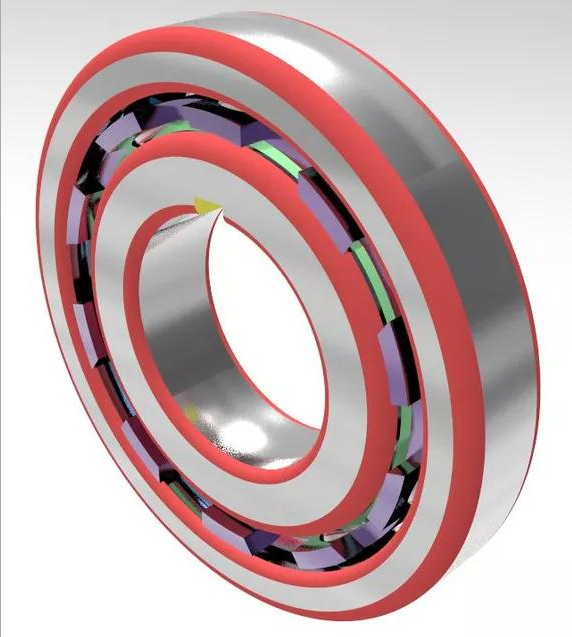

Introduction If you belong to the agricultural sector, you must be aware of the importance to use right bearings in agricultural sectors so that the agricultural equipment must be able to withstand, corrosion, vibrations, and hard mechanical influences. Some of the most common bearings used in agricultural sectors are listed below: Deep-Groove Ball Bearings Angular Contact Ball Bearings Tapered Roller Bearings Ball Bearing Un...

...

Bearing packaging is an important step in bearing export. Improper packaging will bring many problems to bearing products and customers, resulting in unnecessary losses and trouble. Case example: Many bearing suppliers will encounter the problem of bearing packaging, especially large bearings. We learned about this case of bearing packaging complaint from a producer. Bearing type:24044CA.W33.S1,Product weight:39kg,Packaging me...

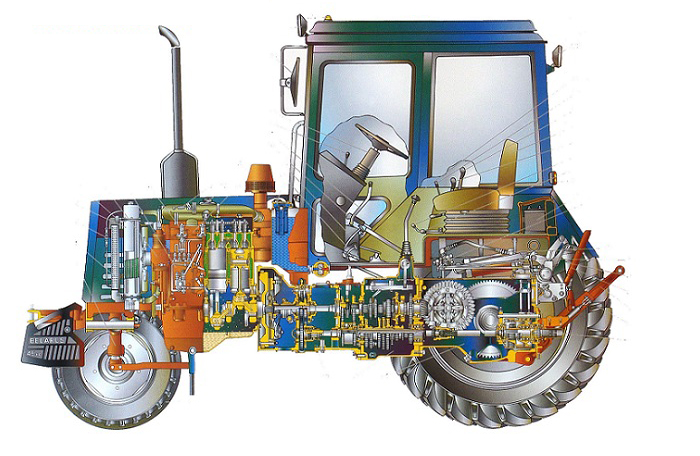

Agricultural engineering involves a wide range of machines, equipment and implements. This ranges from tillage machines, tractors, tedders and balers to powerful harvesting equipment such as forage harvesters or combine harvesters. Even if the machines are very different, the operating conditions are always harsh. In summer, dust and sand place high demands on the bearing seals, whereas during the spring and fall, moisture is a real cha...

The chassis is the support of construction machinery, which can make the overall unit run in the specified direction at the speed and traction required for operation. According to the characteristics of the traveling system, there are 2 main types of construction machinery chassis: 1.Wheeled chassis, including transmission system, braking system, steering system, traveling system. 2. Tracked chassis, including transmission system, steer...

Difference between high-speed and low-speed bearings Many people may misunderstand it, it’s not that the rotation speed of the bearing itself, but its linear speed. Many low speed bearings can reach tens of thousands of revolutions per minute, on the other hand, for some high-speed bearings, the data of rotations per minute maybe only just a few hundred. There are also some other differences between the two. Generally, low-speed b...

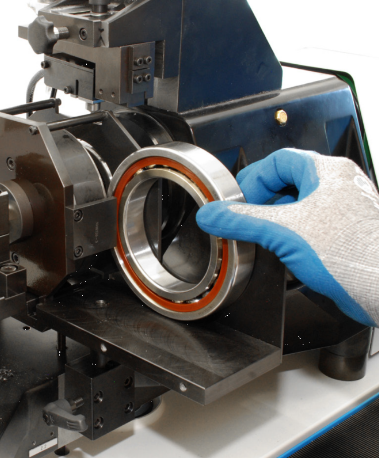

When bearings are 100% inspected with all dimensions on approved drawings based on GB or ISO standard, we confirm bearings are qualified. Here we would like to share you with a case: One day we received an urgent request from our customer, that they asked us to deliver one SL bearing (full complement cylindrical roller bearing) to them in short time, reason was that the bearings delivered from their current supplier were rejected by the...

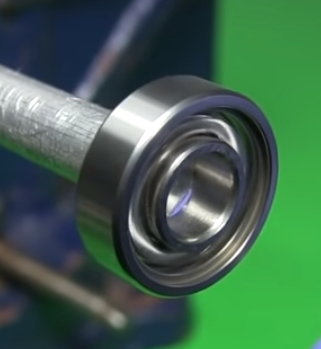

The type of machinery is different, the service conditions of the bearings will be different, and the performance requirements are also different. Generally speaking, there are more than two bearings that would be used on a shaft. In order to facilitate axial positioning, most of the bearings are used as fixed-end bearings, and the rest are used as floating-end bearings. The following table lists the choice of fixed end and floating end...

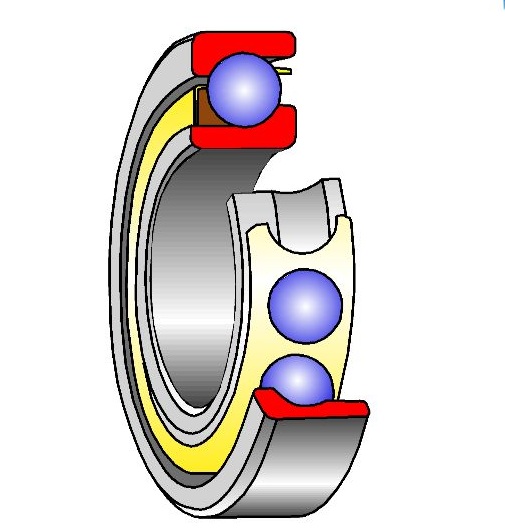

Bearing Selection Guide The types, structures, and sizes of rolling bearings are diverse. In order to make the mechanical device play the expected performance, it is very important to choose the most suitable bearing. To select a bearing, many factors need to be analyzed. The general sequence is as follows: (1) Understand the operating conditions of mechanical devices and bearings, etc. (2) Clear requirements for bearings (3) Select the...

Have you ever noticed the types of cage guidance of your bearings? Basically, there are 3 types: outer-ring-rib guidance, inner-ring-rib guidance, and rolling-element guidance. Unfortunately, big part of Chinese factories, including big brands, don’t put their eyes on cage guidance. They believe various types of cage guidance are interchangeable. You may get NU2310 with MA brass cage with outer-ring-rib guidance, even though y...

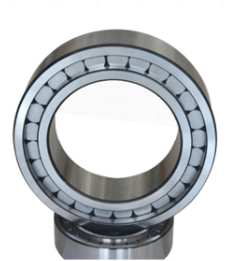

Full complement cylindrical roller bearings are capable of carrying higher radial loads than bearings that utilize a cage and roller design....

There are many types of bearing materials, among which stainless steel is probably one of the most commonly used bearing materials. Compared with ordinary bearing steel (Chrome steel GCr15/100 Cr6/SUJ2), stainless steel bearing not only have obvious advantages in material, but also much strict in process and precision control than ordinary bearing. It is more stable, has low noise and stronger anti-rust and anti-corrosion properties, it...

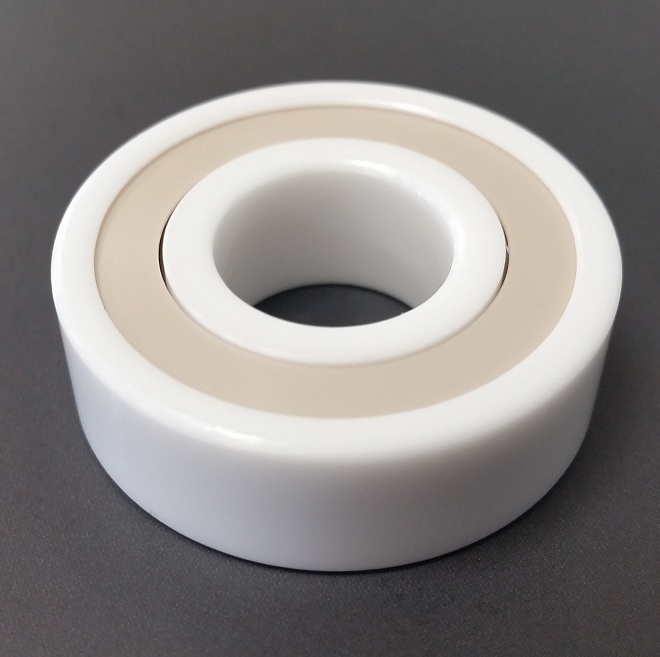

Full ceramic bearings have the characteristics of magnetoelectric insulation, wear resistance, corrosion resistance, oil-free self-lubrication, high temperature and cold resistance, which can be used in extremely harsh environment and special working conditions. Material ZrO2 has perfect properties such like suitable for low and high temperatures, high load capacity, corrosion resistance, nonmagnetic insultated and self-lubrication. Thu...

Apprehensions about a steel shortage in China are unfounded and the recent price increases have largely been a result of short-term market-related factors, experts said. “There is no shortage of supplies. The price surge is not an exact reflection of the current supply and demand situation,” said Wang Jing, an analyst with the Lange Steel Information Research Center. On Monday, steel product prices, tracked by the center, ro...

With the development of mechanical manufacturing industry towards high precision and high speed, the application range of bearings is more and more wide, and the performance requirements of bearings are also higher and higher, especially in some special working environment, metal bearings can not adapt to the demand, or even can not work at all. Because of its low density, high modulus of elasticity, low coefficient of linear expansion,...

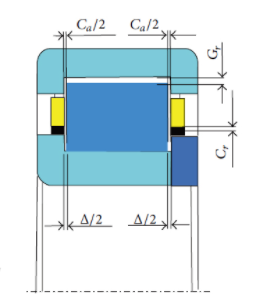

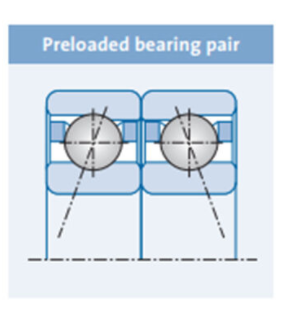

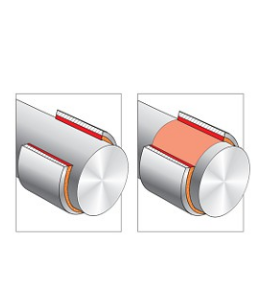

Bearing is an important part of mechanical rotation, and its stiffness and working temperature will directly affect the bearing efficiency on the mechanical operation. In order to provide the rotation accuracy of the bearing, increase the rigidity of the bearing device, and reduce the vibration of the shaft when the machine is working, the preloaded rolling bearing is often used, such as the spindle bearing of machine tool. The bearing ...

TBB family is getting bigger and bigger. The only constant is the smile on our faces, and sincerity to our clients....

Since the second half of 2020, affected by multiple factors, bearing raw materials have increased significantly. At the end of the year, the price of bearing steel has increased by nearly 30%. Bearing steel has a net increase of 1300 yuan per ton, while bearing steel pipe has a net increase of 2800 yuan per ton. By the end of January 2021, bearing steel has increased by another 300 yuan per ton, with an increase of 35.6%. Coupled with t...

Powder metallurgy (PM) is a technology that uses metal powder or nonmetal powder or its mixture as raw materials to manufacture metal materials, composite materials and various types of products through forming and sintering. Its three core elements are technology, materials and equipment, which are widely used in transportation, machinery, electronics, aerospace and other important industrial fields. It is the most potential and dynami...

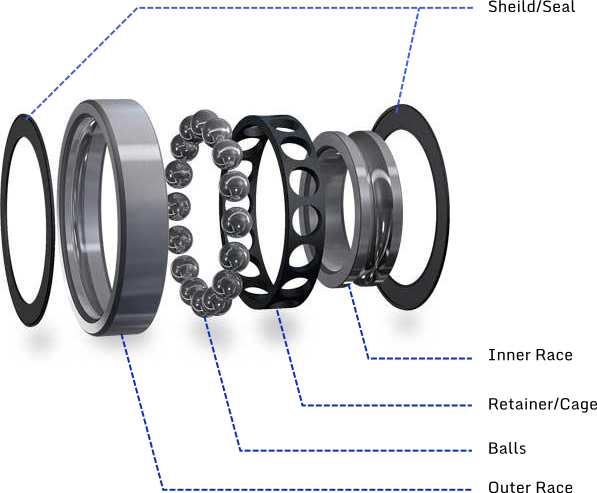

Sealing devices can generally be divided into static seals (fixed seals) and dynamic seals (rotating seals). The former is called gasket seal, and the latter is called gasket seal....

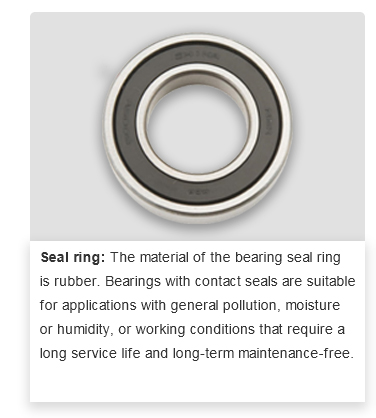

Sealing is indispensable for bearings. Sealing can not only prevent the leakage of lubricant, but also prevent the invasion of harmful foreign bodies. Otherwise, it will cause the abrasive wear of the bearing raceway, reduce the service life of the bearing, and make the bearing parts corroded by harmful gas and moisture, and accelerate the aging of the lubricant. ...

These News About Bearing Industry You Must Know in 2021...

The number of electric and hybrid cars on the road is on the rise leading to innovation in the bearings used on the production line. Nobody could have predicted the huge number of electric and hybrid cars on the road worldwide today....

“Maintenance-free” is an industry-wide term used to describe plain bearings and rod ends with self-lubricating sliding contact surface combinations. These so-called maintenance-free bearings and rod ends offer a number of advantages for OEMs and end users alike. These advantages, which include minimal maintenance and reduced lubricant consumption, quickly compensate for the difference in the initial purchase price. And of course, t...

Here are some examples of applications in which spherical roller bearings might be used: Vibration Screen Bearing, Wind turbine bearings, Papermaking mills bearings, Continuous Caster bearings & etc....

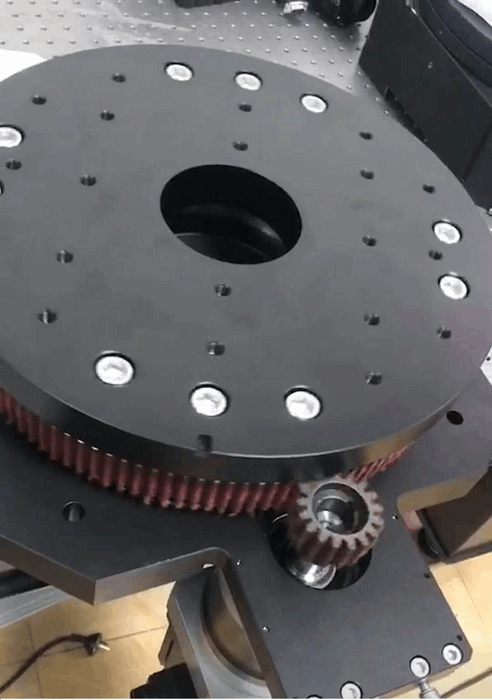

Here you can find some application cases for slewing bearings used in indoor EVs...

Spherical Roller Bearings have many different structures, such as CC type, CA type, E type from SKF and MA type, MB type, E1 type from FAG. Now let me give you a detailed introduction of the difference between these designs....

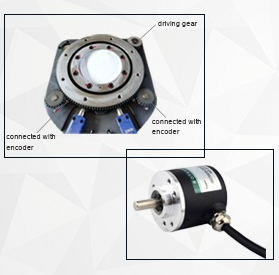

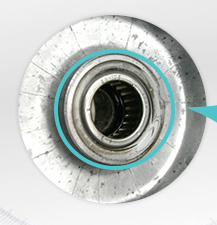

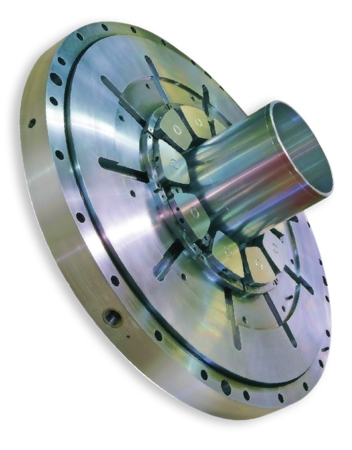

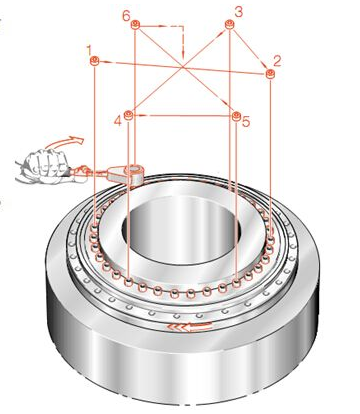

Slewing bearings usually have a diameter ranging from 0.2 to 10 meters. They consist of mounting holes, internal or external ring gears, lubricating oil holes, and sealing devices. The mounting holes are divided into through holes and threaded holes. Different for different industries The slewing bearing has a variety of structural types to meet its requirements, and can meet the needs of the main engine function with different manufact...

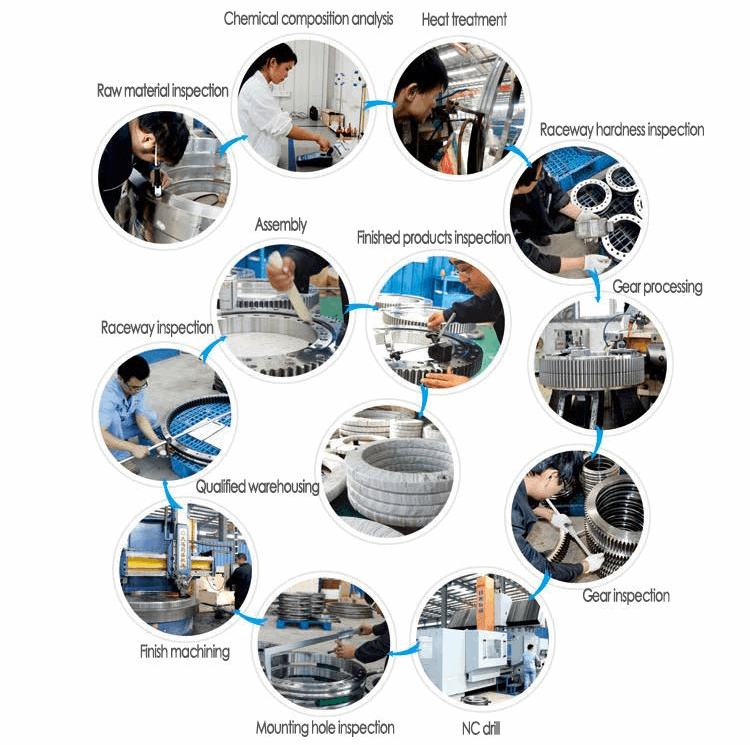

Slewing Bearing, also known as slewing ring bearing, turntable bearing, slewing ring, etc, is widely used in modern industries. Types of Slewing Bearing Single-row ball type (01 series, HS series, Q series)Double-row ball type (02 series)Three-row roller type (13 series)Single-row cross roller type (11 series)Double-row ball type (07 series) )Light and non-standard specifications series slewing bearing Manufacturing Processing Raw mater...

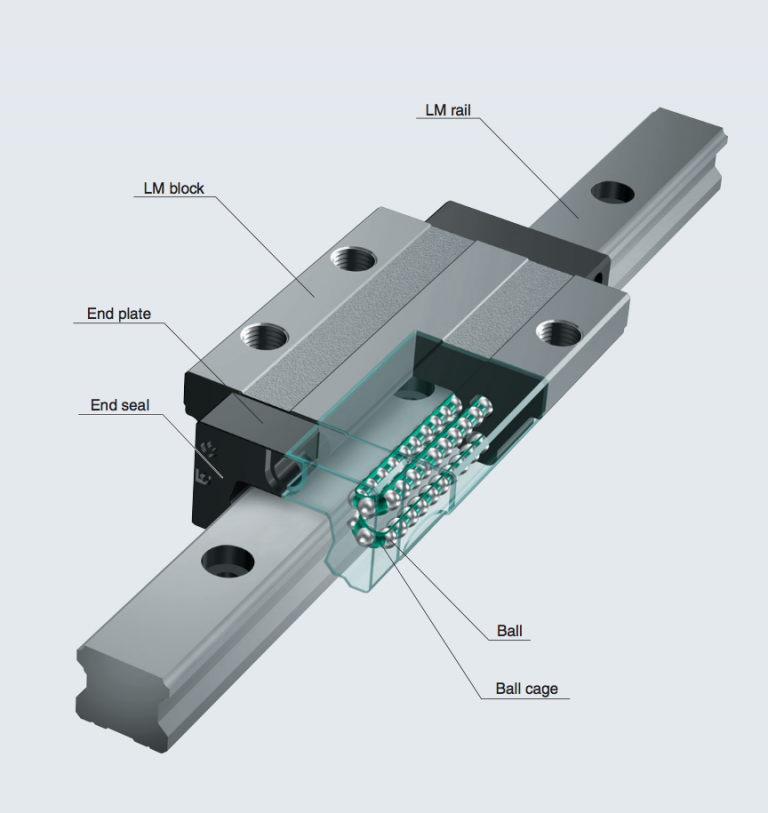

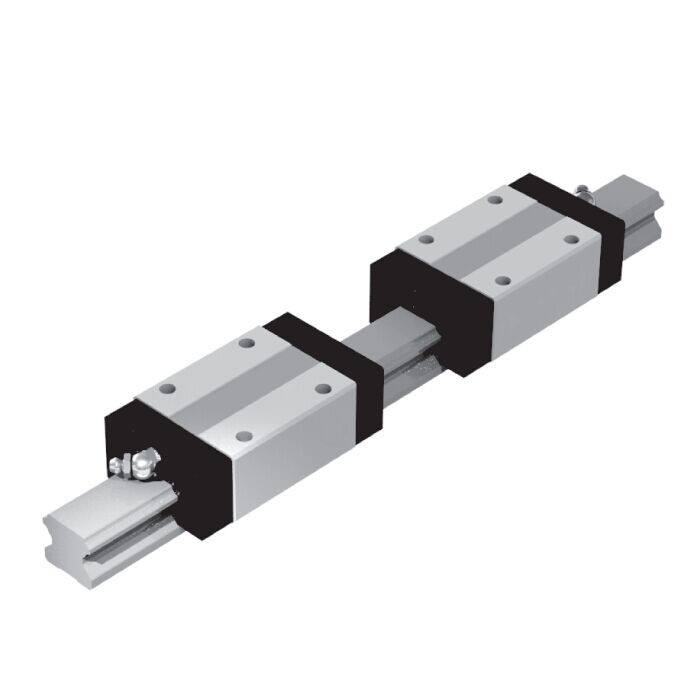

Its construction is simple and cost-effective. The N/O linear guideway assumes the task of being the lateral linear guideway for the table. As the surface guideway is adjusted level with the N/O, the linear guideway systems can be interchanged – depending on whether the grinding spindle is mounted to the right or left....

The majority of angular contact bearings use phenolic type cages and these are exceptional good for a wide range of conditions and particularly for high-speed since they are outer ring located. However, there are advantages to using TYN cages in certain applications, particularly in grease lubrication. TYN is a polyamide material and this cage is designed to be ball guided. Reduced Cage Noise In certain applications cage noise can occur...

No one knows who invented the planetary gearbox, but it has been in use since the 15th century.Planetary Gearboxes is an old mechanics fundamental that is still being used for new eading innovative technology like 3D printing, and new methods of transport. Planetary gearbox consist of an internal toothed ring gear to which are set 3 planets mounted on the planet carrier engaging also with the sun gear and reduced output speed is taken t...

/..: Standardized rolling bearings with uncoded inner diameters A: Single row angular contact ball bearing with 30° contact angle AC: Single row angular contact ball bearing with 25° contact angle ACD: Single row angular contact ball bearing, optimised internal design, 25° contact angle ADA: Double row full complement cylindrical roller bearing with wide snap ring grooves in outer ring, two inner ring halves held together by U-shaped...

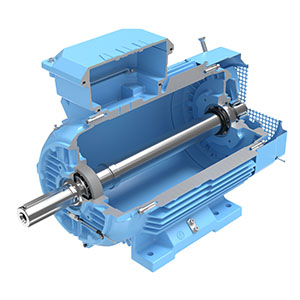

Key Factors of Electric Motor Bearing Design –Outline dimensions–Load size and direction–Speed requirements, constant/variable/high–Material of motor shaft and housing–Power take-off transmission form–Motor installation form–Vibration level requirements–Noise level requirements–Temperature requirements–Bearing life–Lubrication form–Maintenance–Condition mon...

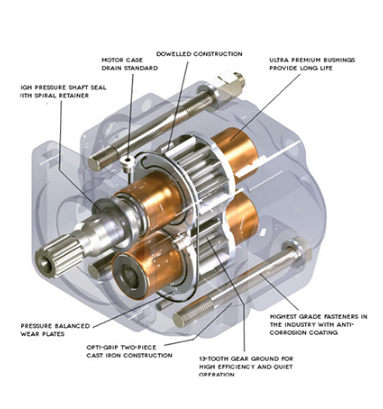

From the elevator you take at work to the dump truck you see rolling by on the street, hydraulics are everywhere. But hydraulic machines are nothing without their hydraulic pumps.The hydraulic pump is the component of the hydraulic system that takes mechanical energy and converts it into fluid energy in the form of oil flow. This mechanical energy is taken from what is called the prime mover (a turning force) such as the power take-off ...

I was once a piece of iron Coming through a great deal of difficulties Smelting from iron ore Until the billet is formed Continuously quenching from lots of processes Built me an indomitable and undaunted spirit And was toughened and hardened into steel. I have thought it would be free of suffering from now on But with a big BANG I was thrown into the furnace again The burning of fire The beating of a hammer Forged me into a ring That m...

Design Variants To allow the bearings to accept the maximum number of balls, four point contact ball bearings are designed with split inner ring or with split outer ring so these bearings have two basic types, one is featured two half inner ring(QJ series), the other is featured two half outer ring(QJF series). TBB four point contact ball bearings have the contact angle of 35°. We can both provide QJ series and QJF series on request. T...

NSK has developed a new ultra-high-speed bearing ideal for electric vehicles, including battery electric, hybrid, and other new energy vehicles. The new bearing enables electric motors to operate at higher speeds, improving fuel economy (reducing power consumption per unit distance), increasing maximum vehicle range, and contributing to enhanced user comfort. NSK is targeting 10 billion yen in sales by 2030. 1. Development Background Pr...

Size from 2mm to 6m Bearings vary in sizes. The smallest “miniature bearing” in the world is with ID 0.6mm× OD 2.0mm× Thickness 0.8mm, which is used in micro motor. The large-size bearing, with an outer diameter of 6m and a weight of more than 15 tons, is used in the large shield machine for tunneling. This kind of large bearing is used when excavating the cross sea tunnel under the Dover strait connecting Britain and Fran...

With the wide application of PWM and IGBT in motor, the problems caused by electromagnetic damage such as electric corrosion of bearing are more and more prominent. What causes electromagnetic damage of bearing? Common mode voltage is the main cause electromagnetic damage. When the bearing is running at high speed, there will be a fluid oil with strong insulation between the roller and the inner & outer raceways. Due to the constant...

A casual visitor was called Novel Coronavirus when we were preparing to celebrate the Spring Festival in January 2020. Because of it, billions of people in our country could not go out, the malls were all closed. Many medical personnels rushed to the front line of the battlefield, here we show our most sincerety to all the medical staff and volunteers who rushed to the front line. Although the epidemic is terrible, lovely Chinese people...

What is the preload of crossed roller bearings? Generally, rolling bearings have a certain clearance under working conditions. However, in order to achieve a specific purpose, when the cross roller bearing is assembled, apply a certain internal load through adjustment of the clearance to achieve negative clearance. This method is called preload. What are the benefits of preload of crossed roller bearings? 1.Improve the Rotation Accuracy...

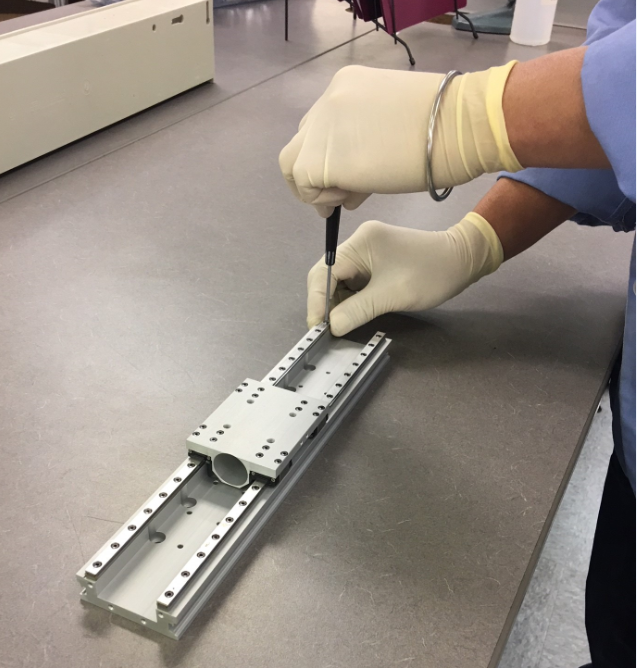

Since bearings are metallic products they rust easily. So their treatment requires certain precautions. 1. When handling bearings, use finger caps, pincers or gloves that do not generate cotton fibers. 2. When you must use naked fingers, first make sure they are clean and free from perspiration and dust. Then apply a quality mineral oil to the fingertips before touching the bearings. Do not use hand cream, as it may induce rust. 3. If a...

The performance of ball bearings can be critically affected by minute particles. Particles as small as 0.005mm can cause problems. To prevent such problems, we use a class 1,000 clean room throughout our bearing assembly operation. “Keeping bearings clean” is the most important rule of bearing use. Avoid exposing bearings to any environment where particles may be present. Once inside a bearing, such particles can cause racew...

Although 2019 was a tough year, TBB have made a lot of achievements with our efforts. We hope in 2020 TBB will win customers’ heart with TBB professionalism, and make greater achievements. In the coming May, TBB will join 2020 China International Bearing Industry Exhibition. We will be there waiting for you!...

After offering we heard many times voice of “Your price is too high” or “Our current price is 50% lower than yours ” …You have explained to customer that how good quality your product is, showed your testing reports with thousands times, because you know clearly the difference between products of different price level. How do you prove it? Yes, taken inspection for these different products is a good method . TBB did so.How...

5 Reasons to Choose TBB Needle Roller Bearing 1. Years of focusing on bearing, quality guaranteed Estabilished for many years since 1998 and is a professional supplier of bearings With an annual output of tens of millions of bearings, the production capacity is sufficient 2. Strict production process Recognized by many famous companies in the world, such as Bonfiglioli, Iveco, Cummins, Carraro, etc. Bearing accessories for w...

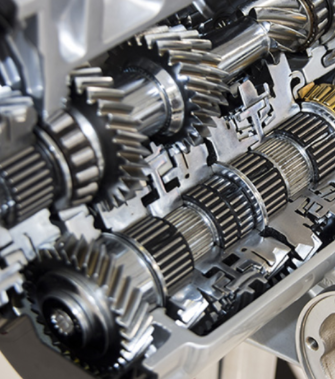

Gearboxes are used in a very wide range of industrial fields. Thanks to the use of gearboxes, a small rotation force (torque) can be used to produce a much greater rotation force, and a slow rate of revolution can be speeded up. In many industries, the gearbox, which is the equipment that transmits mechanical power, is an essential piece of equipment. This step-up unit is the: heart of a wind turbine transmission in an automobile the re...

At this year’s Hannover Messe in Germany, bearing manufacturer NKE Austria GmbH presents bearings with black oxide finish. The protective layer improves run-in and wear characteristics and protects against environmental effects. Especially in critical applications such as wind turbine gear boxes, black oxide finish is a cost-effective and technically viable means of prolonging the service life and performance of rolling bearings. The ...

TBB drawn cup needle roller bearings is formed with thin steel plate through precision punching with very sectional height and big load capacity. This kind of bearings are especially applicable to the big quantity production with economic demands. Stable combination is used between the needle bearings and the bearing cage. No axle fixture is required. Even under high speed and heavy load condition, the bearing functions can be fully mai...

Material Cronidur30ISO Standard: DIN 1.4108Chemical formula: X30CrMoN15-1Advantages: Finer structure, less heat generated, higher permissible contact pressure, much higher fatigue life reliability (10x compared with GCr15 in best case), better corrosion resistance and high temperature resistance Material Ceramic Si3N4Advantages: Excellent tribological properties, lower density to improve the bearing kinematics, lower coefficient of th...

A GROWING NUMBER OF “BARGAIN” BEARINGS are being brought into the Heavy Duty Truck and Trailer marketplace by bearing brokers whose primary emphasis is on price. They ignore the critical issues of product integrity, performance, and supplier support. Initially the price has some attraction, but testing performed by Hyatt and other major suppliers has proven that a much superior performance is achieved from a quality pro...

Wheel hub problems are often discovered while ruling out other sources for the squealing and grinding sounds coming from that area of the vehicle or the gradually increasing vibration noticed by the driver. Because such symptoms – odd noises, vibration, deterioration in handling, etc. – The common to a variety of suspension and steering system parts, it is often through the process of elimination that the need to replace this part i...

Stainless steel and chrome steel are normally corrosion-resistant, not easy to rust. However, improper storage or handling at high humidity, condensation environment will reduce bearing life. How does the corrosion of bearings happen? If the bearing is prolonged exposure to water can cause rust. With the passage of time can cause peeling and crack formation, which are premature bearing failures. In addition, if the bearing is too loose ...

The manufacturing of metal parts and components is so significant to any economic marketplace, typically, the machine tool industry is utilizing the latest technological advances in manufacturing processes. Here we’d like to talk about machine tool SPINDLE BEARING Most spindles use a combination of angular-contact ball bearings and cylindrical roller bearings. The angular-contact types install at a spindle work end because they ha...

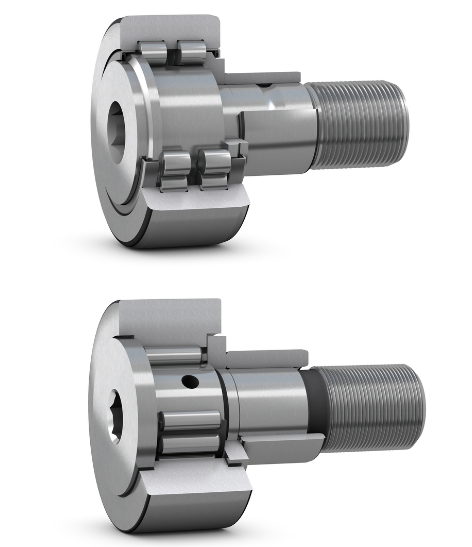

TBB Track Roller is a bearing unit composed of machined thick-wall outer ring, needle rollers or cylindrical roller sets, or cage guidance or full complement needle roller, inner ring or bolt and seal. Featuring multiple compact structure, high rotating accuracy, large varieties, broad adaptability and easy installation, it can bear high radial load and certain shock load and is widely used in machine tool, metallurgical, textile and pr...

Whether you use cam follower bearings for cam followers, or for track, guide, or support rollers, their performance depends largely on the type you select. Important factors include loads, speeds, misalignment, installation, and lubrication. Cam follower bearings are used mainly in three types of applications: following the surface of a cam, supporting linear motion components, or laterally locating components during linear movement. Of...

From 2009 to 2019, it has been 10 years since TBB Shanghai office estabilished.With 10 years growth, no matter wind or rain, the way we go together, the warmth hidden in the bottom of every TBB member’s heart. Lisa, Sales General Manager in TBB, also the elder sister of TBB lady team. Under her leadership, TBB Bearing Provision is moving forward steadily. Let’s see what Lisa wants to say at this special occasion Heidi, Customer Mark...

Needle bearings are roller bearings with rollers that have high length-to diameter ratios. They are used in farm and construction equipment, automotive transmissions, small gasoline engines, gear pumps, small appliance and tool motors, alternators, and aircraft controls. Needle bearings are roller bearings with rollers that have high length-to diameter ratios. They are used in farm and construction equipment, automotive transmissions, s...

Most rolling-element bearings are either ball or roller bearings. The roller bearing family consists basically of cylindrical, tapered, spherical, and needle bearings. Needle roller bearings are the smallest and lightest of the roller bearing family. That gives them specific advantages for certain applications, particularly those requiring reduced weight and space. The high roller length-to-diameter ratio helped give the bearings their ...

If you are a cyclist looking to make your bike lighter and help you boost your cycling performance, easily make it possible by upgrading to Ceramic/Hybrid Bearings. TBB Ceramic and Hybrid bearings are specially designed for bicycle related applications such as wheel hubs, bottom brackets, and chain tensioner pulleys, etc. They have been proved to reduce riders pedalling watts. We use G5 grade ceramic balls, to meet up to highest cycling...

When bearing steels are in their soft (unhardened) state, metallurgists refer to their structure as being in the pearlite state. In order to harden the steel it must be heated to a very high temperature and then cooled very rapidly. When heated in the heat treat furnace to 1,750°F, the structure transforms from pearlite to what is known as austenite. After quenching (very rapid cooling), the structure then transforms from austenite to ...

Self-lubricating bushings are used where the bearing must operate without lubricant or with marginal lubricant. Our focus is on ensuring that the bearing gives the best performance and the longest life under various conditions. The working principle of self-lubricating bearings is that, during the initial run-in period of the bearing, there will be a solid lubricating film created by the transfer of a small amount of material from the...

In our previous blog entry, we examined static and dynamic load ratings for spherical plain bearings. This week, we continue our look into this bearing segment with some further information on the operating life of spherical plain bearings, and factors which can shorten or extend their use. The service life of a spherical plain bearing operated under mixed or dry friction conditions is determined by the increase in bearing clearance o...

Dynamic and static load ratings for spherical plain bearings are important for understanding the life of a bearing, but what do each specify? Read on to learn more about these important classifications. Dynamic Load Rating for Spherical Plain Bearings Dynamic load rating is used for calculations when the spherical plain bearing is subjected to dynamic stress. It represents the load, constant in magnitude and direction, under which a bas...

We have assembled a wide variety of frequently asked questions (FAQs) about bearings (e.g. ball bearings, roller bearings, plain bearings, linear bearings) and bearing related products (and bearing services too). Just refer to the question you’re interested in below and you will be taken to a remarkably succinct, straight-forward, and accurate answer: Q1: Can bearings be refurbished? Yes, but it depends… Generally speaking, for ...

1) High carbon chromium bearing steel High carbon chromium bearing steel specified in JIS is used as a general material in bearing rings (inner rings, outer rings) and rolling elements (balls, rollers).Their chemical composition classified by steel type is given in “Table 13-1 Chemical composition of high carbon chromium bearing steel”.Among these steel types, SUJ 2 is generally used. SUJ 3, which contains additional Mn and...

Since the characteristics of materials used for cages greatly influence the performance and reliability of rolling bearings, the choice of materials is of great importance. It is necessary to select cage materials in accordance with required shape, ease of lubrication, strength, and abrasion resistance. Typical materials used for metallic cages are shown in Tables 13-3 and 13-4. In addition, phenolic resin machined cages and other synth...

In shipping bearings, since they are covered with proper anti-corrosion oil and are wrapped in antitarnish paper, the quality of the bearings is guaranteed as long as the wrapping paper is not damaged. If bearings are to be stored for a long time, it is advisable that the bearings be stored on shelves set higher than 30cm from the floor, at a humidity less than 65%, and at a temperature around 20℃. Avoid storage in places exposed dire...

Periodic and thorough maintenance and inspection are indispensable to drawing full performance from bearings and lengthening their useful life. Besides, prevention of accidents and down time by early detection of failures through maintenance and inspection greatly contributes to the enhancement of productivity and profitability. Cleaning Before dismounting a bearing for inspection, record the physical condition of the bearing, including...

It is important for enhancing productivity and profitability, as well as for accident prevention that abnormalities in bearings are detected during operation.Representative detection methods are described in the following section. 1)Noise checking Since the detection of abnormalities in bearings from noises requires ample experience, sufficient training must be given to inspectors. Given this, it is recommended that specific persons b...

In selecting bearings, the most important thing is to fully understand the operating conditions of the bearings. The main factors to be considered are listed below: 1.Installation space Bearing can be installed in target equipment When a shaft is designed, its rigidity and strength are considered essential; therefore, the shaft diameter, i.e., bore diameter, is determined at start.For rolling bearings, since wide variety with different ...

Bearings with diameters between 36 and 169 in. typically cost a lot and have long lead times, forcing end users to keep spare bearings on hand or face extensive downtime should a bearing fail. Therefore, it can make sense to replace a bearing before it degrades. Bearings removed this way often make good candidates for repair or refurbishment. But what qualifies a bearing as repairable? How are repairs carried out? And what kind of resul...

Massive rotors in hydroelectric generators, large ball mills, rolling mills, large electric motors, and steam and gas-turbine generators normally operate with great efficiency on oil films in sleeve and thrust bearings. But trouble arises when rotational speed is too low, as it is at starting and stopping, to generate a complete oil film. Then frictional drag and wear increase with metal-to-metal contact between the bearing and rotating...

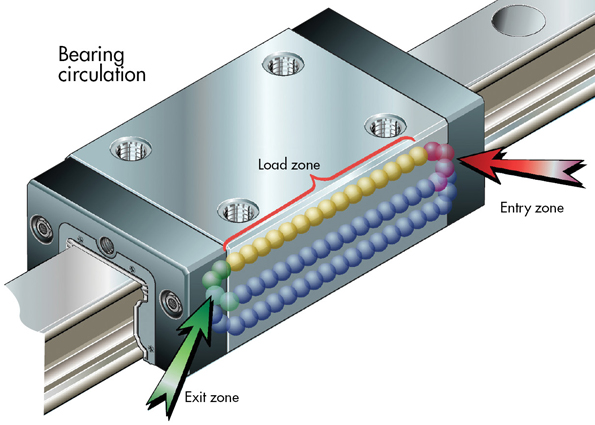

Caged balls offer several benefits, ranging from minimized wear to reduced maintenance. Let’s look deeper into caged balls, their benefits, and design tips for success. Caged balls are widely deployed in motion systems throughout industry. Whether used in ball bearings, linear guides, or ballscrew actuators, caged balls bring both performance and practicality. The addition of the cage minimizes wear, reduces noise, and extends mainten...

For instrument bearings, certain special considerations should be emphasized: Heavy press fits should be avoided. Accuracy of mounting surfaces should be equal to accuracy of mating bearing surface. Misalignment for low torque and running accuracy should not exceed 1/4°. Loading across the bearing during assembly should be avoided. Axial positioning: Accurate axial positioning of the shaft relative to the housing requires shoulder...

Scoring and wiping are two common causes of oil-film bearing failure. Scoring is characterized by circular parallel grooves on the bearing lining surface and are heavier at the load zone. Wiping results in the displacement of babbitt from one location to another. If you see air-moving equipment, chances are oil-film bearings lie at the heart of centrifugal and axial fans. Serious damage can result to the entire unit should these bearing...

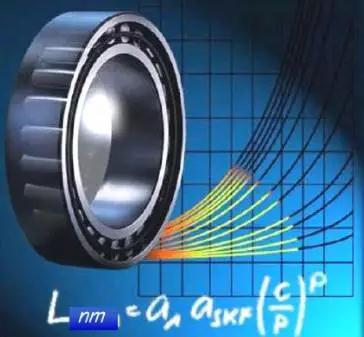

How long will a bearing last? Standardized life equations help to answer. Relative effects of contamination and lubrication condition on bearing life with different load levels. Experience shows seemingly identical rolling bearings operated under identical conditions may not last the same amount of time. In most cases, it is impractical to test a statistically significant number of bearings, so engineers rely on standardized bearing-lif...

Approximately 27,000 ceramic tiles cover the exterior of the NASA Space Shuttle—a reusable spacecraft that carries astronauts in a low orbit around Earth. Acting as a thermal barrier to the 1,650°C generated by atmospheric re-entry, the tiles illustrate the impressive resistance of ceramic materials. The impressive properties of ceramics are also being used in bearings. Ceramics are primarily used in bearings due to the material’s ...

Thrust bearing are a type of rotary bearing that permits rotation between parts and is designed to support a high axial load while doing so (parallel to the shaft). We specializes in miniature thrust bearings and small thrust bearings. Our ball thrust bearing metric series start with bores as small as 2.0 mm with flat raceways and 3.0 mm with grooved raceways with outside diameters of 6.0 mm and 8.0 mm respectively. Some important facto...

Small to midsize OEMs that now source rotating-equipment products and services through multiple vendors may want to consider using a dedicated, local distributor. Distributors have access to a broad product range and can readily supply related items such as bearings, electric motors, belts, and gearboxes. This simple tactic of consolidating your supply source will immediately provide tangible benefits, including one-stop shopping, a sin...

Get out the surgical gloves when working around the most fragile of bearings. Dynaroll miniature ball bearings make a dime look large. (Left)Grooves make room for adhesive to flow without raising runout. (Right)Make sure the shoulder rim clears the opposing ring when locating a bearing against a shoulder in a mating part: Maximum shaft shoulder diameter = Outer ring land diameter – clearance Minimum housing diameter = Inner ring l...

Limiting speed values for instrument bearings are almost impossible to determine. However, generalizations may be made. Bearing size: Highest speeds may be obtained with the smallest bearing. However, extremely small miniature bearings usually have a thin, weak retainer and their maximum speed is less than medium-size miniatures. Load: Limiting speed is directly affected by the magnitude of applied load. Heavy loads result in ...

Heat is generated either by shearing of the oil film or by rubbing contact. In hydrostatic and hydrodynamic bearings, heat generation at running speeds is the result of oil shear, and the amount of temperature rise can be estimated if oil viscosity and shear rates are known. Temperature can be regulated by controlling the oil flow through the bearing or by using external cooling. Heat is generated either by shearing of the oil film or b...

Bearing torque is the moment required to overcome internal friction to start or maintain rotation of one ring while the other is stationary. Torque or friction generally increases when: Bearing size is increased because a larger ball and retainer must be moved. Load is increased because of greater deformation and resistance to rolling motion. Speed is increased because of increased lubricant drag. Lubrication type is a critical torque f...

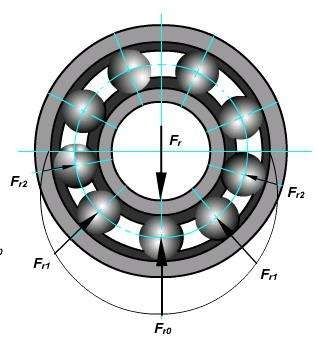

In some applications, allowable load seriously influences selection. Major variables affecting load capacity are ball size and number and internal geometry of the bearing. Static: Primary consideration is given to static ratings. A bearing may be deformed permanently by high loads on nonrotating bearings or severe instantaneous loads on rotating bearings. Radial static capacity for instrument bearings is defined as the load ca...

Even with the most-sophisticated motion controller, designers can still find it difficult to attain precise linear motion unless the mechanical components are appropriately designed for the application. Here are six mechanical and structural factors that affect control-engineering performance. Armed with even with the most-sophisticated motion controller, engineers can still find it difficult to attain precise linear motion unless the m...

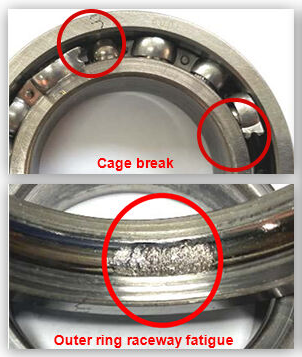

Damaged bearings lead to downtime and lost productivity. Find out how to prevent the damage before it’s too late. The top bearing “killers,” or causes of damage and premature end of bearing life, are inadequate lubrication, contamination, overload, and improper handling and installation. They affect cylindrical, spherical, needle, tapered, and ball bearings. When they strike, they force companies to pay for repairing and replacing...

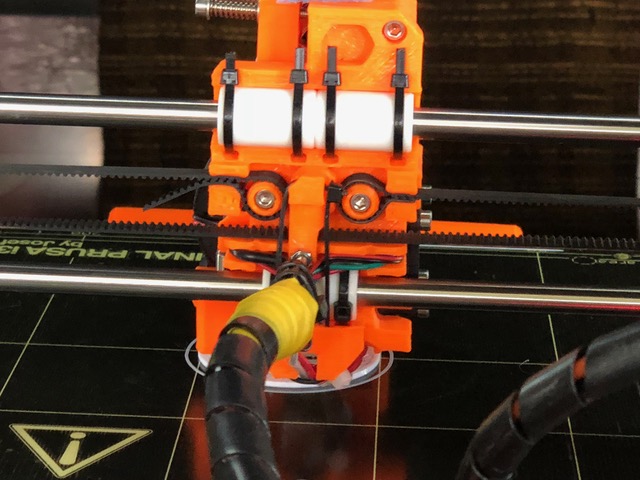

The goal is smooth, jerk-free motion, long-life, durability, and low cost to improve the quality or parts made by 3D printers. Are bearings or bushings best for 3D printers? And how can they be improved so that 3D printers can more quickly and reliably turn out parts of higher quality? Although increasing the quality and speed of 3D printers involves all the components used in them, a good place to start are the bearings and bushings th...

Whether you use cam follower bearings for cam followers, or for track, guide, or support rollers, their performance depends largely on the type you select. Important factors include loads, speeds, misalignment, installation, and lubrication. Cam follower bearings are used mainly in three types of applications: following the surface of a cam, supporting linear motion components, or laterally locating components during linear movement. Of...

Linear guides are precision mechanical assemblies that operate as part of a system. As such, they can only perform to the degree that they are properly integrated into the overall machine. Merely specifying the appropriate guide is not enough. Building a system that operates as intended requires a clear understanding of how to specify, design, install, and test the linear guide. Here, we discuss several of the most common errors made by...

The rolling elements in antifriction bearings are critical components that can affect the overall performance of an entire machine. Engineers must consider their many attributes to get the best bearing performance, including: • Diameter and diameter tolerance. • Axial profile • Radial clearance • Surface finish In many cases, catalog data alone does not provide enough information for engineers to confidently specify a bearing an...

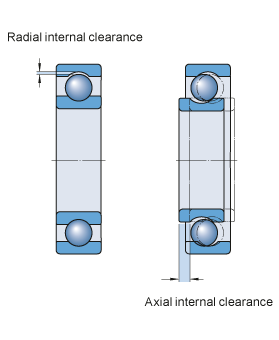

Internal Clearance Internal Radial Clearance of ball and roller bearings is an important parameter in obtaining proper machine operation, optimal bearing life, and a reasonable operating temperature. It is the total distance one bearing ring moves relative to the other radially (radial internal clearance) or axially (axial internal clearance). Categories Initial internal clearance: in the bearing prior to mounting. Mounted clearan...

When someone tell you that your bearings are expansive Tell them it is not expansive but WORTHY. When someone says your bearings are expansive, answer them like this: Porsche, Land Rover are expansive, but more and more people drive them.Santana is cheap, but it is eliminated by more and more peopleNokia is cheap, Iphone is expansive, but more and more people use Iphone and it made Apple the most valuable company in the world, while a...

Bearings made by normal steel or carbon steel, or even repaired from defective ones, e.g. GCr15 V.S. GCr9… Unqualified bearings counterfeit big brand products, from bearing marking to outside packaging & quality certification. The seller counterfeits authorized distributor or sales office of big brands. The seller sells second-hand products but at best quality price. The seller passes normal grade to high-grade ones. The selle...

Custom linear bearings can help solve unique problems. Understanding what situations demand a custom linear bearing is key. Each application is a little bit different. For every load that can be perfectly supported by a stock bearing, there are others that require a customized solution. A project may involve specialized environments, extreme performance demands, tight scheduling, and more. Let’s focus on some of the techniques enginee...

“Bearings are as good as their lubrication”. The lubrication is the most important factor for bearing life. Several actual statistics show that incorrect lubrication causes more than 50% of premature bearing failures.A correct lubrication must cover: 1. The correct lubricant. Oil or grease? Viscosity? Temperature range? Anticorrosive properties? EP properties? Consistency of the grease? Etc. 2. The correct lubrication system...

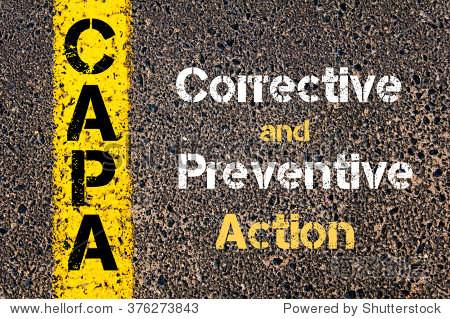

Introduction to Six Sigma In today’s information age, news spreads faster than ever. When an event happens halfway around the world it can become common knowledge within hours or even minutes. Companies must guard their reputation for producing quality products. A single, significant quality incident could result in irreparable damage to brand equity and consumers trust. While there are many quality systems in use today, one methodolo...

Introduction to Failure Mode and Effects Analysis (FMEA) There are numerous high-profile examples of product recalls resulting from poorly designed products and/or processes. These failures are debated in the public forum with manufacturers, service providers and suppliers being depicted as incapable of providing a safe product. Failure Mode and Effects Analysis, or FMEA, is a methodology aimed at allowing organizations to anticipate fa...

Introduction to Problem Solving In the current world market, consumers and organizations have a vast amount of choices regarding the brand or manufacturer of products, parts and materials available to them. In order to not merely survive but thrive in this ever increasingly competitive market, an organization must provide the most value and the highest quality possible. Most organizations have effective quality systems in place. Unfortu...

Introduction to Corrective Action Preventive Action (CAPA) When illness strikes and we need medical attention, we put our trust in the medical products and care givers to provide relief. We expect the care we receive is without fault. Fortunately, failure is not experienced frequently in healthcare and medical devices. When failure does occur, we demand a rigorous process of investigation be initiated to identify why it occurred. Correc...

Now we have the correct equipment for the corresponding application and now comes the turn to the installation. An incorrect installation can reduce the useful life of an equipment due to premature failure caused by several defects. The effects are shown in the following graph: The most common errors in the installation of equipment that reduce the life of the bearings are: 1. Misalignment of the shaft in relation to the driving equipme...

Bearings for Car Gearbox Bearings for Car Air Conditioning Compressor...

Motorcycles have become popular all over the world as a convenient means of transportation, and wherever they are found there will always be bearings rotating. Large numbers of bearings are used in motorcycles. Actual numbers vary depending on the model and other structural factors, but a single motorcycle will have around 20 to 30 bearings built in. These bearings are used in key revolving parts, supporting the vehicle’s running, inc...

There’s always a chance that things break. Same with bearings., but it doesn’t mean that we can’t prevent those issues beforehand to avoid further troubles. The below chart will show you how bearing failure comes and what we can do to prevent it ahead of time to make your application much stronger. With the above knowledge, you don’t have to wait for the symptoms of a bearing failure before you take actions, which can help sa...

● What is 8D Problem Solving? When a claim exists and the customer issues you a corrective action, what should you do? No doubt, you should follow the 8D (Eight Disciplines) problem-solving methodology system that is designed to find the root cause of a problem, devise a short-term fix and implement a long-term solution to prevent recurring problems. When it’s clear that your product is defective or isn’t satisfying you...

TBB Case of Needle Roller Needle Roller Bearing Used in JAC Gearbox MF70B Heavy Duty Cam Followers – Stud Type Track Rollers Comments from TBB Customer...

Crankshaft, an essencial mechnical part, plays a great role in engine of motorcycle.Motorcycle crankshaft is made of several seperate pieces, today we only focus on the failure analysis of needle roller bearings used in crankshaft. Cause of crankshaft damage Generally it is because the oil’s not replaced in time. There are bearings in crankshafts. The bearing will wear seriously without oil or with poor lubrictaion, a gap may occur, t...

There are many bearings used in various active parts of a motorcycle (such as the direction column, the front and rear wheels, the rear chain plate, the rear gearbox, etc.). Bearings produced by regular manufacturers are generally tested as qualified products at the factory, but it is also important to install them correctly. During the usage of motorcycle, if the bearing ball cage falls off, the working surface in the rolling groove wi...

Riding a bicycle is a common excercise way in our nowaday life. But how much do you know about one of the most important parts in a bicycle–BEARING? Please allow me to show you here. Which parts are bearings used in a bicycle? Bearings are used in bicycles mainly to reduce friction. Normally you can find bearings used in the following parts: 1. The front and rear hubs of the wheels 2. The bottom bracket(BB) where an axle con...

Case No. 1 TBB optimized products can work under higher load rating with longer lifetime. Case No. 2 Case No. 3 Bearing Durability Test Comparison — Needle Roller Bearing HK1010Application: Automotive automatic gearboxTest purpose and method: Bearings run a test continuously under constant radial load. The durability test component level test were run on both TBB and INA, the test results:1, Total test time is about 2870hours and...

● Significance & Application of CQI-9 HTSA The North American automotive association AIAG (Automotive Industry Action Group) is the publisher of the CQI standards (Continuous Quality Improvement). CQI-9 Heat Treatment System Assessment is a self-assessment of the heat treatment system and must be carried out at least once a year.This standard is an appendix to ISO TS 16949 (IATF 16949) under ?customer-specific requirements“ and ...

1. TBB Busy April 2. TBB Handcraft Lesson Look, except bearing, we also had many fun times in office! On the second week, TBB members enjoyed very interesting handcraft lessons at office. The handmade Husky card-bag was so cute! The purse also looked great! Maybe the new year gift of 2020 you get would be our handmade something. 3. TBB Take Action on Earth Day ● Lessen Paper User Try using email, PDF’s, electronic documents, CD-ROM�...

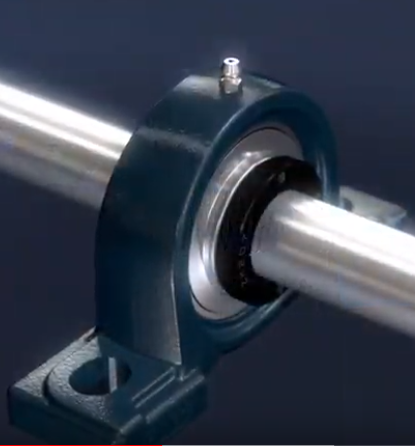

Introduction Have you ever heard about ball-bearing units? Or do you want to know about all the basic knowledge associated with ball-bearing units? No matter what the question is, this article will help you know everything that you need to know about ball-bearing units. If you belong to a mechanical industry, you must be aware of the uses of ball bearing units in machine parts available in the market. Ball bearing units, instead of quit...

what full-complement cylindrical roller bearings are, common types of full-complement CRBs, those ones popularly used in the gearbox sector, and the reasons and the key quality control points....

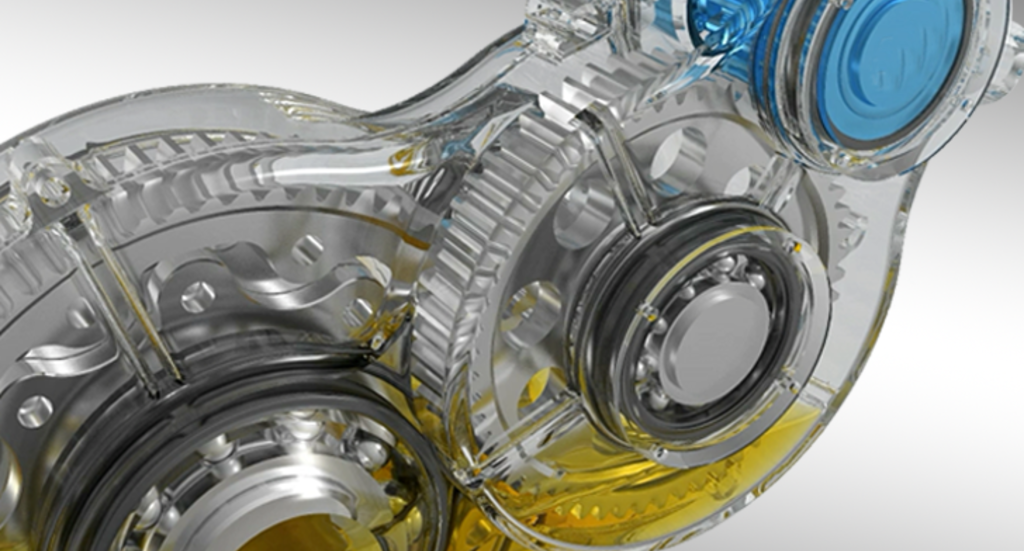

“How do we know which lubricant is the most appropriate for the gearbox application?” Has this question even come to your mind? According to our research, this is the hottest topic our readers pick up for us....