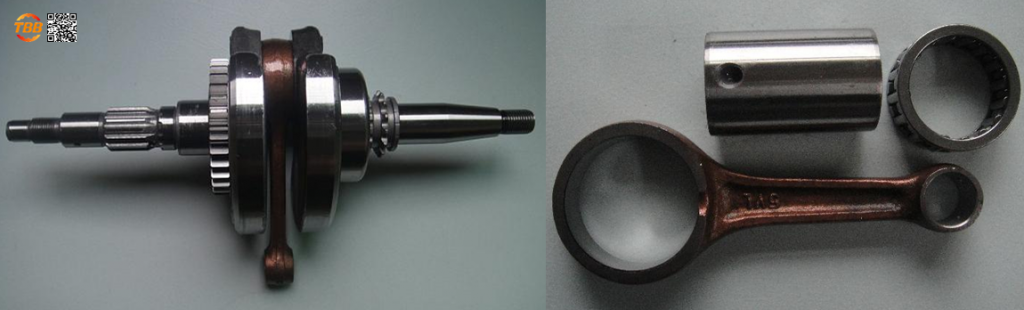

Crankshaft, an essencial mechnical part, plays a great role in engine of motorcycle.

Motorcycle crankshaft is made of several seperate pieces, today we only focus on the failure analysis of needle roller bearings used in crankshaft.

- Cause of crankshaft damage

Generally it is because the oil’s not replaced in time. There are bearings in crankshafts. The bearing will wear seriously without oil or with poor lubrictaion, a gap may occur, the crankshaft will shake, and the engine will produce abnormal noise

- FIVE reasons cause bearing failure in crankshaft

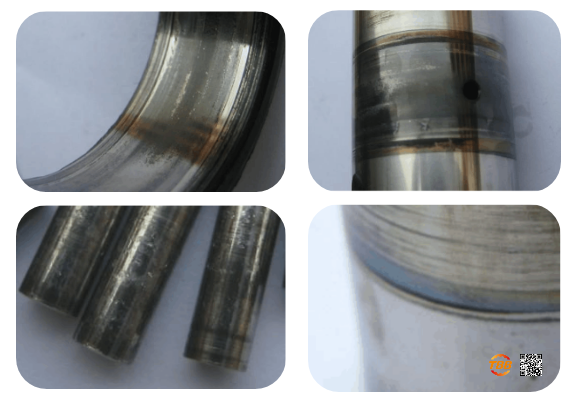

1. Pitting

Reason: defects on metal surface, particle contamination, or lubricating oil contaminated with metal particles

After the bearing pitting occurs, strong vibration, noise and heat usually happen when operation

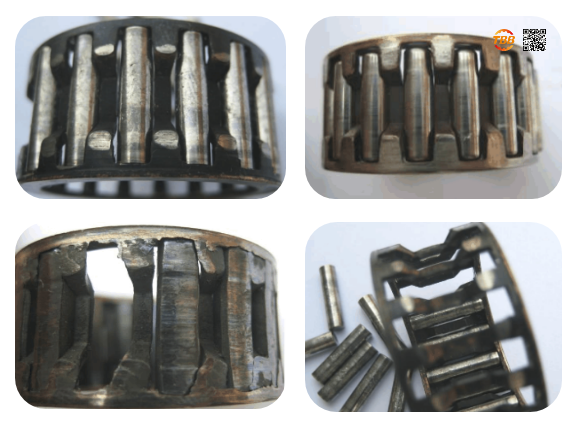

2. Fatigue peeling off

It is caused by excessive impact loads, such as rough road condition or overloads

After several impacts for some time, the sheet-like fatigue spalling occurs at the indentation. In that case there may follow noise, vibration and additional torque, which will seriously affect the running stability and accuracy of the bearing

Influence factors:

- Material smelting quality

- Heat treatment status

- Surface processing accuracy

- Surface residual stress

- Lubricating oil, plastic deformation of contact surface

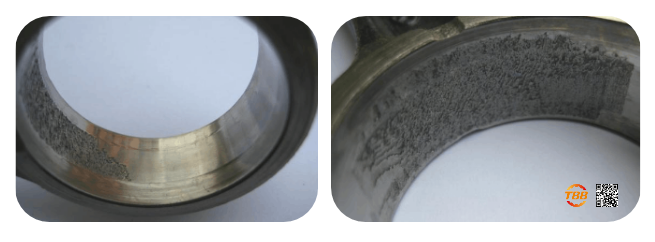

3. Wearing failure

Extrusion of external hard particles or microscopic protrusions of the friction surface between the friction surfaces of the bearing parts, cause the friction surface wearing and leave fine groove marks

4. Burning Damage

The needle roller bearing is poorly lubricated, excessive load or preload is too large, too fast engine speed, too large clearance, water and foreign matter invading; poor accuracy of the connecting rod, etc

5. Plastic deformation failure

- Why not disassemble the motorcycle crankshaft rashly

The maintenance of the crankshaft is complicated. Under normal circumstances, do not dismantle it, unless it is found that the big end of the connecting rod is excessively loose during maintenance (mostly is due to excessive usage of the engine or lack of lubricating oil for a long time, which cause serious damage upon the connecting rod big hole, roller and crankshaft). Decomposition of the crankshaft is quite difficult (some crankshaft connecting rods are indestructible since manufactured), requiring not only higher technology but also certain decomposing equipments. Therefore, under normal circumstances, do not disassemble the crankshaft. Even if it is decomposed, try to avoid repeated disassemble, which is because each time it is decomposed, the possibility of crankshaft damage increases. Practice has proved that some crankshafts are not serious in the original malfunction, improper decomposition not only can not eliminate the original malfunction, it adds new malfunction and even causes the crankshaft to be scrapped.

One Comment

Like!! I blog quite often and I genuinely thank you for your information. The article has truly peaked my interest.