With the wide application of PWM and IGBT in motor, the problems caused by electromagnetic damage such as electric corrosion of bearing are more and more prominent. What causes electromagnetic damage of bearing? Common mode voltage is the main cause electromagnetic damage. When the b犀利士 earing is running at high speed, there will be a fluid oil with strong insulation between the roller and the inner & outer raceways. Due to the constant change of common mode voltage, fluid film is charging and discharging, leading to currents. It has a continuous thermal effect on the lubricant, which will cause deterioration, deficiency, carbonization of lubricant, thus affecting the life of bearing. Under the deficiency of lubricant, the shaft current directly passes through the bearing and discharges on the contact surface of the bearing, which will cause teeth electric erosion along the rolling direction. When the common mode voltage on both sides of the fluid film is too large, the fluid film will be broken down, resulting in EMD currents. It will cause electrical erosion pits on the raceway, which usually need to be observed under the microscope. And the raceway appears dim and tarnished. Solution In PWM Frequency Modulation Motor, EMD…

A casual visitor was called Nove壯陽藥 l Coronavirus when we were preparing to celebrate the Spring Festival in January 2020. Because of it, billions of people in our country could not go out, the malls were all closed. Many medical personnels rushed to the front line of the battlefield, here we show our most sincerety to all the medical staff and volunteers who rushed to the front line. Although the epidemic is terrible, lovely Chinese people will not be afraid. Take a look at the interesting things happened during the epidemic. 1. Attitude changes 2. About Divorce Continue: A few years later, the son came back from school and asked the father, “Why are so many people born in the same month same year as me, papa?” The father sighed and told his son, “Son, It all starts with a bat…” 3. Right Time for Contribution 4. A Good Idea I have an idea: 15 masks, take turns to use, one piece a day, and then seal the used one. By the 15th day, use the first one again, because the new coronavirus on the first one should be dead after 14 days, so it’s a safe mask again. How…

The performance of ball bearings can be critically affected by minute particles. Particles as small as 0.005mm can cause problems. To prevent such problems, we use a class 1,000 clean room throughout our bearing assembly operation. “Keeping bearings clean” is the most important rule of bearing use. Avoid exposing bearings to any environment where particles may be present. Once inside a bearing, such particles can cause raceway scratches, abrasion and shortened life. They can also generate acoustic noise and vibration. We use shields or seals to keep particles out. But there is still a gap between the shield and inner ring of shields and non-contact seals. This gap may permit particle entry. So it is important to observe the following procedures carefully. 1. Keep your bearing handling area as clean as possible. 2. Do not remove the bearings from their packaging until just before use. If you move the bearings to a container, be sure the container is clean. Its lid should be kept closed and it should be cleaned every day to prevent particle accumulation. 3. Never use a bearing that has been 壯陽藥 dropped. It may be brinelled (race track dented). In use, a brinelled bearing will generate…

Although 2019 was a tough year, TBB have made a lot of achievements with our efforts. We hope in 2020 TBB will win customers’ heart with TBB professionalism, and make greater achievements. In the coming May, TBB will join 2020 China International Bearing Industry Exhibition. We will be there waiting for you!

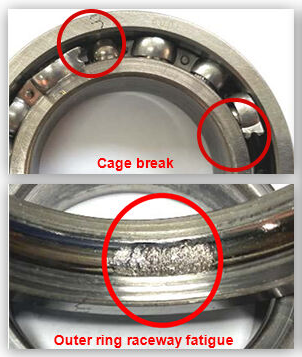

After offering we heard many times voice of “Your price is too high” or “Our current price is 50% lower than yours ” …You have explained to customer that how good quality your product is, showed your testing reports with thousands times, because you know clearly the difference between products of different price level. How do you prove it? Yes, taken inspection for these different products is a good method . TBB did so.However, the testing of basic data such as size, clearance, precision, vibrate. Sometimes there have very big different on measurement, but sometimes there do not have very obvious different on data. What is the deep reason for big price gap? To end the confusion, TBB did further testing- Life Reliability Comparison Test at National Bearing Testing & Inspection Institute.A group of 4 piece of deep groove ball bearings, after rigorous and reasonable experimental process: Firstly, can you guess how the bearings performed ? Here comes some pictures to show how it performance. Secondly, 犀利士 can you guess how many hours the bearings lasting? Here comes the testing results. #1 bearing from TBB OEM product, it lasting for 121.5 hours till the testing ended with good condition.#2 bearing from world well-known…

5 Reasons to Choose TBB Needle Roller Bearing 1. Years of focusing on bearing, quality guaranteed Estabilished for many years since 1998 and is a p壯陽藥 rofessional supplier of bearings With an annual output of tens of millions of bearings, the production capacity is sufficient 2. Strict production process Recognized by many famous companies in the world, such as Bonfiglioli, Iveco, Cummins, Carraro, etc. Bearing accessories for world-renowned companies throughout the year Obtained the quality management system certification 3. Variety of specifications Can also provide customized solutions With comprehensive bearing R & D capabilities, covering all important aspects of bearing industry chain and can provide customers with cost-effective solutions 4. 90% of the basic products can be shipped within 4 weeks guarantees your productivity 5. Quality after-sales service Professional one-on-one guidance consultants, let you worry free after sales With more than 1000 sets of molds to choose from, the cost and time of mold opening can be saved Technical guidance consultants are provided to support your application of bearings Asking for more information, contact us.

Gearboxes are used in a very wide range of industrial fields. Thanks to the use of gearboxes, a small rotation force (torque) can be used to produce a much greater rotation force, and a slow rate of revolution can be speeded up. In many industries, the gearbox, which is the equipment that transmits mechanical power, is an essential piece of equipment. This step-up unit is the: heart of a wind turbine transmission in an automobile the reduction gears in a Ferris wheel By supplying bearings for gearboxes such as these in support of their most important function: “revolving,” we believe that it can even be said to be supporting the world. However, because there are many instances where the breakdown of a gearbox would have serious implications, extremely high reliability is demanded. 犀利士 Naturally, we seek to ensure that its designs closely match customer needs, and the company is always aiming to enhance product quality. We supply bearings that offer long life to reduce equipment maintenance costs, can handle high load capacities, and are extremely reliable. We will continue to pool our comprehensive strengths. With environmental issues firmly in its sights, our company will continue product development efforts so that…

The manufacturing of metal parts and components is so significant to any economic marketplace, typically, the machine tool industry is utilizing the latest technological advances in manufacturing processes. Here we’d like to talk about machine tool SPINDLE BEARING Most spindles use a combination of angular-contact ball bearings and cylindrical roller bearings. The angular-contact types install at a spindle work end because they handle both axial and radial loads. The other end houses a cylindrical roller bearing which, by design, floats or slips axially to compensate for spindle thermal expansion yet operates with zero radial clearance for rigidity. The basic requirements for spindle: High running accuracy High speed Wide range of speed High rigidity Low temperature rise High reliability Some of the above requirements are in confrontation, so it’s almost impossible for spindle to meet all the above requirements simultaneously. Therefore, the main performance of spindle should be taken into consideration when designing spindle supp犀利士 orting. Bearing types and matched method depend on machine tool different performances.

Needle bearings are roller bearings with rollers that have high length-to diameter ratios. They are used in farm and construction equipment, automotive transmissions, small gasoline engines, gear pumps, small appliance and tool motors, alternators, and aircraft controls. Needle bearings are roller bearings with rollers that have high length-to diameter ratios. They are used in farm and construction equipment, automotive transmissions, small gasoline engines, gear pumps, small appliance and tool motors, alternators, and aircraft controls. Needle bearings are usually lubricated with grease, but oil or oil-mist lubrication is preferred for heavy-duty or high-speed applications. Many light-duty bearings never require relubrication, but high loads or speeds demand it. Compared with other roller bearings, needle bearings have much smaller rollers for a given bore size. They have the highest load capacity for a given radial space of all rolling-element bearings, but their use is limited to bore diameters less than 10 in. All needle bearings are variations of two basic designs. The first, full complement, has a full complement of needles and contains no retainer. The second, caged needle, contains a retainer or cage for roller guidance and spacing. Caged bearings have smaller roller complements and lower load capacities than full-complement bearings. Their…