There have a new bearing steel GCr9 appeared in the market,which supplying for Turkey, Poland and some other Europe countries after-market, let’s get the details of what material as below. From the bearing appearance, there is no difference between GCR9 and GCR15, but for the product performance, there have obvious difference. From the bearing appearance, there is no difference between GCR9 and GCR15, but for the product performance, there have obvious difference. Due to the difference of Cr element content, GCr15 have a better performance of wear resistance than GCr9, usually bearing of GCr15 material working life will be longer. . DANA and TBB have a project of needle roller bearing which applied for hydraulic motor. DANA technical and engineer person have inspected TBB Changzhou factory twice on Feb-26th and last December , and our factory satisfied their high quality OE market requests. . . The bearing world has become quite different in 2018 with the introduction of tariffs, price increase of steel in China, closure of factories due to environment issue and also sudden demand increase. Even though the demand levels have now come back to normal with the easing of steel supply as compared to before the cost…

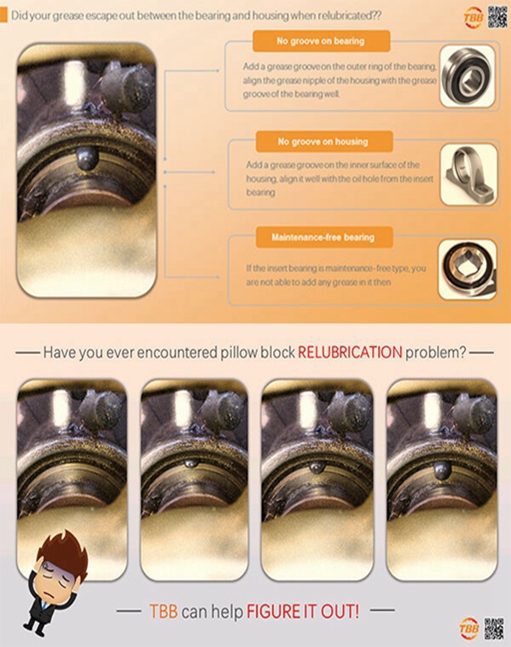

● Functions of a lubricant If rolling bearings are to operate reliably they must be adequately lubricated to prevent metal-to-metal contact between the rolling elements, raceways and cages. Separation of the surfaces in the bearing is the primary function of the lubricant, which must also inhibit wear and protect the bearing surfaces against corrosion. In some applications the lubricant is also used to carry away heat. The choice of a suitable lubricant and method of lubrication for each individual bearing application is therefore important, as is correct maintenance. Lubricants for rolling bearings serve the following functions: * Separate the rolling contact surfaces in the bearing; * Separate the sliding contact surfaces in the bearing; * Protect highly finished bearing surfaces from corrosion; * Provide sealing against contaminants (in the case of grease); * Provide a heat transfer medium (in the case of oil). ● Re-lubrication of pillow block The purpose of any bearing, housed or not, is to reduce the amount of friction between connected or interacting components. The right bearings also reduce the amount of wear-and-tear on the equipment. This, in turn, increases the longevity and operational capabilities of the machinery which requires some form of lubrication. A single…

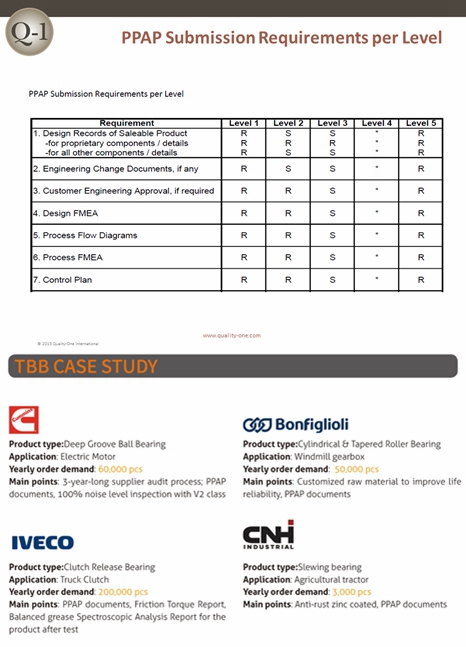

●What is PPAP? PPAP is the abbreviation of Production Part Approval Process, a valuable tool for establishing confidence in component suppliers and their production processes. Initially, PPAP was utilized by the automotive and aerospace industries. PPAP is now being utilized by several industries to improve communication and provide quality products. Within the automotive industry, the ultimate resource for PPAP information is the manual published by the Automotive Industry Action Group (AIAG). PPAP defines the approval process for new or revised parts, or parts produced from new or significantly revised production methods.?It verifies that the supplier understands all customer engineering design specifications and requirements and that the process is capable of consistently producing product meeting those requirements during an actual production run at the quoted production rate. ●How to perform PPAP? The PPAP process consists of 18 elements that may be required for approval of production level parts. Not all of the elements are required for every submission. There are five generally accepted PPAP submission levels. A, 18 elements of PPAP: 1. Design RecordsA copy of the drawing. If the customer is responsible for designing, this is a copy of customer drawing that is sent together with the Purchase Order (PO)….