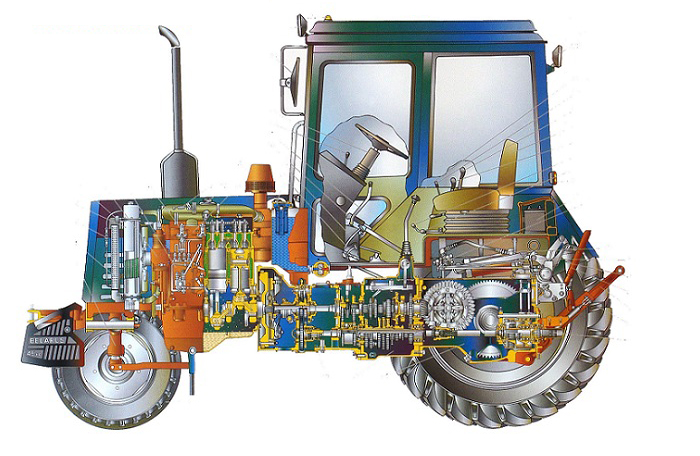

Agricultural engineering involves a wide range of machines, equipment and implements. This ranges from tillage machines, tractors, tedders and balers to powerful harvesting equipment such as forage harvesters or combine harvesters. Even if the machines are very different, the operating conditions are always harsh. In summer, dust and sand place high demands on the bearing seals, whereas during the spring and fall, moisture is a real challenge for farmers. Heavy soils test the mechanical strength of all machine parts to the limit. Constant vibrations and high shocks are loads that occur throughout the entire year. This is why the bearing supports in tillage machines have to be particularly robust. Here we’ll make an introduction about tractor. Although there are many types of agricultural tractors with different structures, they are composed of three parts: engine, chassis and electrical equipment. Following are typical bearing arrangements in agricultural tractors: For further requests on bearings used in agricultural machinery, please make a direct contact with TBB

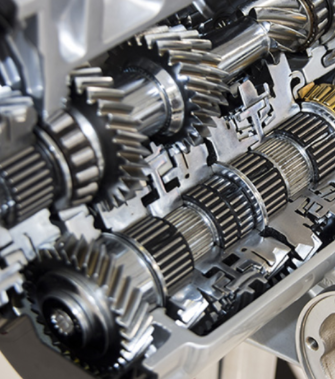

The chassis is the support of construction machinery, which can make the overall unit run in the specified direction at the speed and traction required for operation. According to the characteristics of the traveling system, there are 2 main types of construction machinery chassis: 1.Wheeled chassis, including transmission system, braking system, steering system, traveling system. 2. Tracked chassis, including transmission system, steering system(incl. braking), traveling system, rotary support device(load carrying) Transmission System of Construction Machinery Chassis: The transmission components between the power unit and the driving wheel of construction machinery are collectively referred to as the transmission system. The transmission system is divided into mechanical transmission, hydraulic mechanical transmission, hydraulic transmission and electric transmission. The three main components of transmission system: Gearbox, Differential, Wheel Drive. Gearbox Dual-clutch AT Popular bearing types used: Tapered Roller Bearing Cylindrical Roller Bearing Needle Roller and Cage Assembly 2. AT with hydraulic torque converter Popular bearing types used: Needle Roller and Cage Assembly One-way Clutch Needle Roller Bearing Thrust Needle Roller and Cage Assembly Deep Groove Ball Bearing HK Series Needle Roller Bearing 3. AT with continuously variable transmission Popular bearing types used: Needle Roller and Cage Assembly Tapered Roller Bearing Cylindrical Roller Bearing Deep…

The type of machinery is different, the service conditions of the bearings will be different, and the performance requirements are also different. Generally speaking, there are more than two bearings that would be used on a shaft. In order to facilitate axial positioning, most of the bearings are used as fixed-end bearings, and the rest are used as floating-end bearings. The following table lists the choice of fixed end and floating end bearing structure.

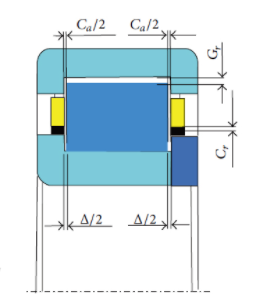

Have you ever noticed the types of cage guidance of your bearings? Basically, there are 3 types: outer-ring-rib guidance, inner-ring-rib guidance, and rolling-element guidance. Unfortunately, big part of Chinese factories, including big brands, don’t put their eyes on cage guidance. They believe various types of cage guidance are interchangeable. You may get NU2310 with MA brass cage with outer-ring-rib guidance, even though you order “NU2310M” with clear requirement of rolling-element guidance. In some cases, it may lead to a serious claim. All these 3 types of cage guidance probably appear in various types of bearings, with performance reasons, bearing design reasons and manufacturing reasons. Attention should be paid to the different performances of different types of cage guidance. The performance difference of these 3 types of cage guidance is mainly reflected in the speed performance under different lubrication conditions. During our research on cage guidance, we got to know something interesting as extra: 1. Brass cage is widely used in high-speed application. 2. There are 4 kinds of gaps between components: radial clearance (Gr), roller gap (△), cage guidance gap (Cr), cage axial gap (Ca), respectively. These gaps are defined as the maximum possible displacements between relative components in radial/axial…

Full complement cylindrical roller bearings are capable of carrying higher radial loads than bearings that utilize a cage and roller design.