Internal Clearance

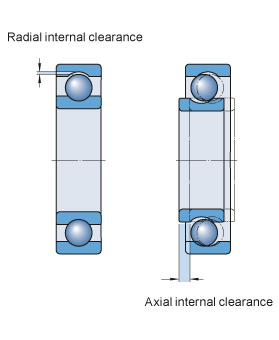

Internal Radial Clearance of ball and roller bearings is an important parameter in obtaining proper machine operation, optimal bearing life, and a reasonable operating temperature. It is the total distance one bearing ring moves relative to the other radially (radial internal clearance) or axially (axial internal clearance).

Categories

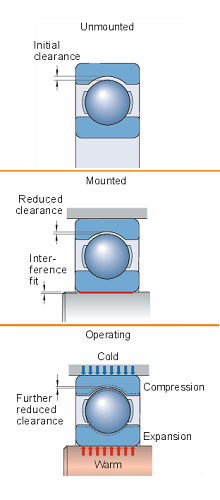

Initial internal clearance:

in the bearing prior to mounting.

Mounted clearance:

in the bearing after mounting but prior to operation.

Operating clearance:

in the bearing when it is in operation and has reached a stable temperature.

Ideally, for optimum bearing life and machine reliability, bearing internal clearance is zero or slightly negative at operating conditions. Initial bearing clearance is chosen during machinery design and bearing selection to reach this goal. And the bearing manufacturer establishes it by controlling bearing internal structure–roller dimension & groove dimension of IR & OR.

Current Standards

GB/T4604.1-2012 [Equal ISO5753.1-2009]: Radial ball bearing–radial clearance

GB/T4604.2-2013 [Equal ISO5753.2-2010]: Four-point-contact ball bearing–axial clearance

GB/T25769-2010: Measuring methods for radial internal clearance

GB/T28698-2012: Deep groove ball bearings for electric motors—Specifications

GB/T32324-2015: Measuring methods for axial clearance of four-point-contact ball bearing

No Comments