Small to midsize OEMs that now source rotating-equipment products and services through multiple vendors may want to consider using a dedicated, local distributor. Distributors have access to a broad product range and can readily supply related items such as bearings, electric motors, belts, and gearboxes. This simple tactic of consolidating your supply source will immediately provide tangible benefits, including one-stop shopping, a single point of accountability, and the preferred services that often come from a close OEM/distributor business relationship. Moreover, distributors can bring the expertise of their suppliers to your organization, including advanced engineering services, ranging from applications engineering, failure and design-life testing, CAD, and vibration/reliability specifications, as well as assembly and warranty information Case in point: A small OEM that builds rope sheaves used in paper-mill dryer sections had recently changed a bearing spec from two single-row, deep-groove ball bearings to a double-row, angular-contact ball bearing. The update looked great on paper, but end users were reporting a significantly shorter bearing service life. The OEM’s distributor brought in SKF to help solve the problem. SKF engineers reviewed the rope-sheave design with computer programs specifically made to analyze bearing operating temperature, loads, raceway positions, and failure modes. The resulting calculations…

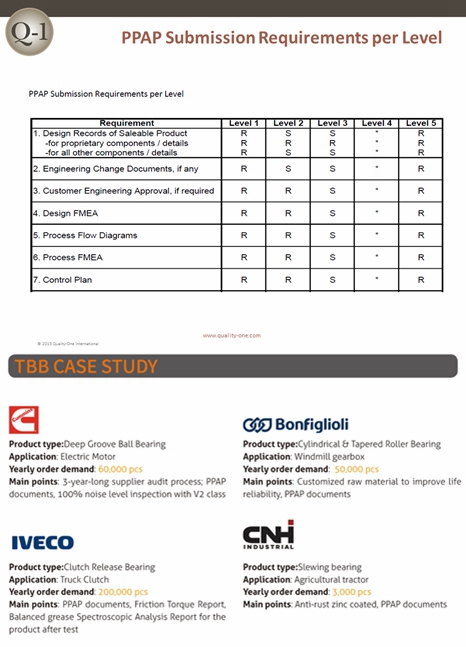

●What is PPAP? PPAP is the abbreviation of Production Part Approval Process, a valuable tool for establishing confidence in component suppliers and their production processes. Initially, PPAP was utilized by the automotive and aerospace industries. PPAP is now being utilized by several industries to improve communication and provide quality products. Within the automotive industry, the ultimate resource for PPAP information is the manual published by the Automotive Industry Action Group (AIAG). PPAP defines the approval process for new or revised parts, or parts produced from new or significantly revised production methods.?It verifies that the supplier understands all customer engineering design specifications and requirements and that the process is capable of consistently producing product meeting those requirements during an actual production run at the quoted production rate. ●How to perform PPAP? The PPAP process consists of 18 elements that may be required for approval of production level parts. Not all of the elements are required for every submission. There are five generally accepted PPAP submission levels. A, 18 elements of PPAP: 1. Design RecordsA copy of the drawing. If the customer is responsible for designing, this is a copy of customer drawing that is sent together with the Purchase Order (PO)….