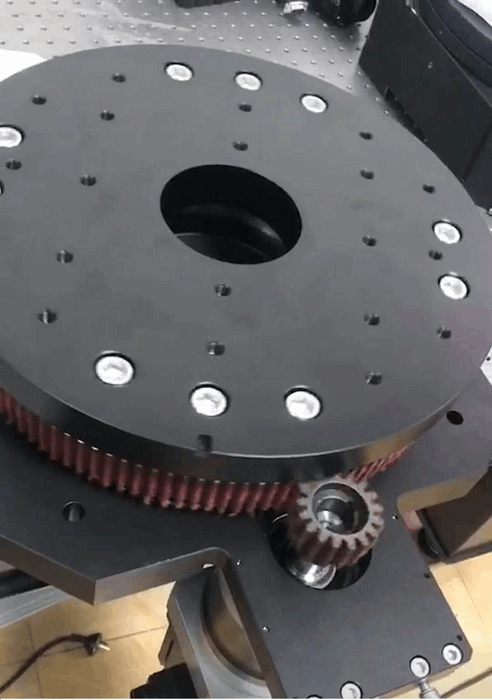

Slewing bearings usually have a diameter ranging from 0.2 to 10 meters. They consist of mounting holes, internal or external ring gears, lubricating oil holes, and sealing devices. The mounting holes are divided into through holes and threaded holes. Different for different industries The slewing bearing has a variety of structural types to meet its requirements, and can meet the needs of the main engine function with different manufacturing accuracy levels. Therefore, the slewing bearing is an indispensable machine on the slewing device of medium and large construction machinery slewing bearing. component. It plays an important role in the machinery industry, construction industry, coal industry and shipbuilding industry. The slewing bearing has toothless type, external tooth type and internal tooth type. The structure types slewing bearing generally include single-volley, double-volley, cross-roller, three-row roller, ball-column combined and other forms, of which single-row ball The slewing bearing has a relatively low cost and excellent overall performance. The double volleyball slewing bearing has certain advantages in service life, strong bearing capacity, small swing resistance, large allowable wear, and strict requirements for the mounting base. Raceway rotation accuracy is low; Crossed roller slewing bearings have high accuracy, long life, and high dynamic load capacity, but have high…

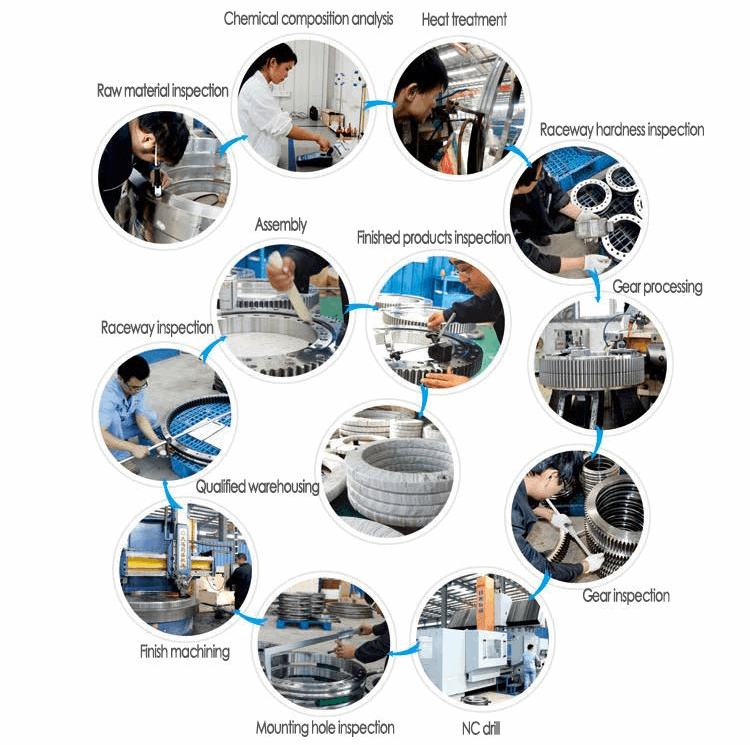

Slewing Bearing, also known as slewing ring bearing, turntable bearing, slewing ring, etc, is widely used in modern industries. Types of Slewing Bearing Single-row ball type (01 series, HS series, Q series)Double-row ball type (02 series)Three-row roller type (13 series)Single-row cross roller type (11 series)Double-row ball type (07 series) )Light and non-standard specifications series slewing bearing Manufacturing Processing Raw material inspection Chemical composition analysis Heat treatment Raceway hardness inspection Gearing processing Gear inspection CNC drilling processing Mounting hole inspection Turning processing Raceway inspection Assembly Finished product inspection Qualified stock In the entire cycle of slewing bearings from forgings to finished products to the hands of customers, the tooth processing technology takes the longest time, and the length of the delivery period depends greatly on the timeliness of the slewing gear processing. Hobbing machining accounts for about 45% of the entire slewing bearing processing volume, or even a larger proportion. For large diameter and large modulus slewing bearing machining, milling gear machining also reflects the characteristics of good machining accuracy, high efficiency, and convenient programming. In recent years, in order to adapt to the improvement of machining precision and production efficiency requirements of slewing bearing processing, the hobbing technology has continuously…