Caged balls offer several benefits, ranging from minimized wear to reduced maintenance. Let’s look deeper into caged balls, their benefits, and design tips for success.

Caged balls are widely deployed in motion systems throughout industry. Whether used in ball bearings, linear guides, or ballscrew actuators, caged balls bring both performance and practicality. The addition of the cage minimizes wear, reduces noise, and extends maintenance intervals. The technology also significantly boosts the lifetime of the device compared to non-cage versions. These attributes have made caged balls the go-to technology for a variety of applications.

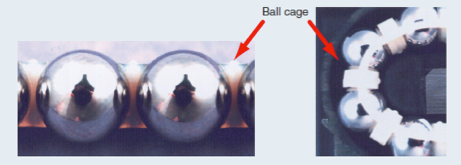

The image above highlights different use cases of caged ball bearings.

Bearing cages consist of polymer structures that are molded to precise shapes. When the bearing is assembled, the balls are loaded into the cages. The cage surrounds the balls, separating them from one another.

Ball cages provide a number of benefits, including:

- Minimizing metal-to-metal contact

- Ensuring orderly ball movement

- Improving high-speed performance

- Retaining grease for longer lifetime

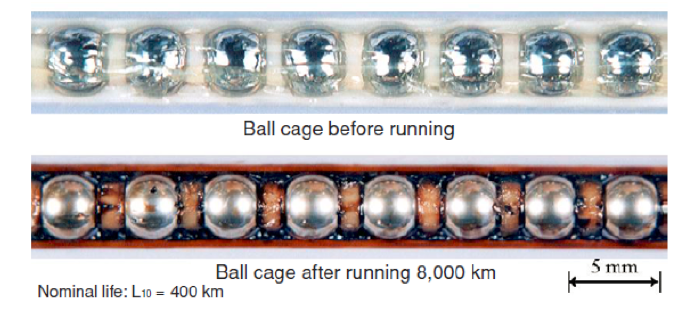

In an extended durability test of THK’s LM guide, a significant amount of the grease originally packed into the bearing (top) remains after the device runs 8,000 km (bottom). (Courtesy of THK)

THK developed caged ball technology and is the premier supplier of caged-ball linear guides and ballscrews in the world.

Proper Specification

Caged balls bring great value to motion systems. In the Motion Solutions Engineering Services Group, caged bearings are our first choice. The following example shows why.

We built a heavy-duty vertical lift for a semiconductor equipment manufacturer. The unit was designed for 24/7 operation with loads on the order of 700 lb. We chose caged-ball linear guides and ballscrews for the design. The actuator operated for an entire year without any maintenance. At the end of that time, we were amazed to see that there was still lubricant left on the balls of both the linear guides and the ballscrew.

The ability to retain lubricant reduces maintenance, decreases unscheduled downtime, and enhances performance. It is also useful from a business standpoint. OEMs typically specify lubrication intervals for their equipment, but end-users often don’t comply. Designing in caged balls means that even if the asset owner doesn’t follow proper maintenance procedures, the OEM can still have confidence that the equipment will operate as expected.

Caged balls are not always a perfect fit, of course. In a few cases, non-caged balls may be a better fit:

- Applications with temperatures over 80°C

- High-vacuum applications

- Extreme-radiation environments

- Applications with extremely light loads, for which the friction introduced by ball cages can present issues

An example of the latter case is a simulator we built for an OEM developing a solar-panel deployment system. The simulator needed to mimic motion in a zero-gravity environment. In this case, the bearing cage would have presented too much friction. We chose to go with a non-caged version.

Tips for Success

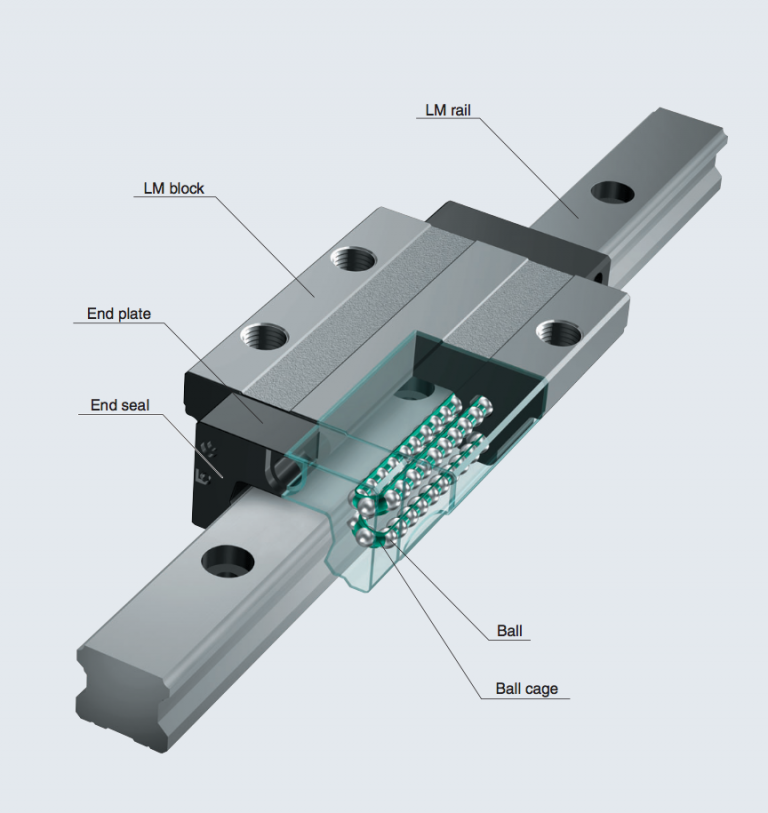

The linear guide shown above demonstrates how caged ball bearings can be used in a guiderail.

Success with caged balls starts with following best practices. Changing lubricants should be approached with caution. The wrong lubricant may degrade the cage material, leading to early failure. It is essential to use a lubricant that has been approved for use with the cage material. An extensive list of lubricants has been approved for use with THK cages; contact Motion Solutions for details.

There are a few misconceptions around caged balls that can discourage machine builders and end-users from working with what is a very effective technology. First, some assume that the additional materials and complexity increase the price compared to non-caged balls. In reality, the cost differential is minimal. Meanwhile, caged balls can deliver great savings by virtue of their grease-holding ability. The lubrication interval is nominally considered to be up to 10 times longer than for a non-caged ball; in practice, we have discovered that under certain circumstances, caged balls can run almost indefinitely between lubrication cycles.

Unfortunately, many designers mistakenly think that caged balls are more expensive, and they will specify a non-caged bearing in hopes of shaving a few dollars off the budget. It is only later that they realize that the small amount they might save with a non-caged design is dwarfed by the higher cost of ownership. For a machine with caged-ball devices, the maintenance interval might be increased from one to five years. More importantly, there is a much lower likelihood of unscheduled downtime, which can cost between thousands and hundreds of thousands of dollars per hour, depending on the application.

Another mistake is to assume that the cage adds a point of failure, decreasing reliability. Certainly, cages do fail on rare occasions, but when properly specified and maintained, this is a rarity. Here, too, the benefits of the extended lubrication intervals far outweigh the chances of the cage coming apart and causing an issue.

Probably the biggest mistake of all is to not use a caged ball if the application is a good fit. Considering all factors, OEMs should specify caged balls whenever possible. The cost difference is negligible and the benefits greatly outweigh any possible difference. In most cases, the result will be vastly reduced maintenance requirements, longer life, and better performance.

Machine Design

No Comments