...

Bearing packaging is an important step in bearing export. Improper packaging will bring many problems to bearing products and customers, resulting in unnecessary losses and trouble. Case example: Many bearing suppliers will encounter the problem of bearing packaging, especially large bearings. We learned about this case of bearing packaging complaint from a producer. Bearing type:24044CA.W33.S1,Product weight:39kg,Packaging me...

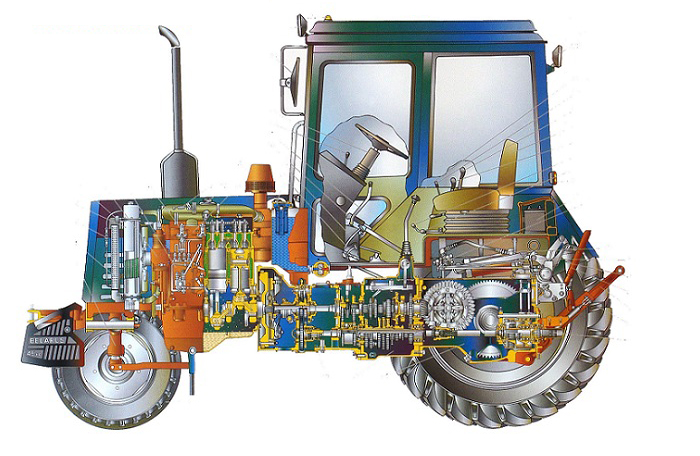

Agricultural engineering involves a wide range of machines, equipment and implements. This ranges from tillage machines, tractors, tedders and balers to powerful harvesting equipment such as forage harvesters or combine harvesters. Even if the machines are very different, the operating conditions are always harsh. In summer, dust and sand place high demands on the bearing seals, whereas during the spring and fall, moisture is a real cha...

The chassis is the support of construction machinery, which can make the overall unit run in the specified direction at the speed and traction required for operation. According to the characteristics of the traveling system, there are 2 main types of construction machinery chassis: 1.Wheeled chassis, including transmission system, braking system, steering system, traveling system. 2. Tracked chassis, including transmission system, steer...

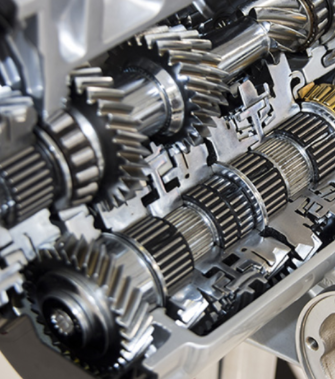

Difference between high-speed and low-speed bearings Many people may misunderstand it, it’s not that the rotation speed of the bearing itself, but its linear speed. Many low speed bearings can reach tens of thousands of revolutions per minute, on the other hand, for some high-speed bearings, the data of rotations per minute maybe only just a few hundred. There are also some other differences between the two. Generally, low-speed b...

When bearings are 100% inspected with all dimensions on approved drawings based on GB or ISO standard, we confirm bearings are qualified. Here we would like to share you with a case: One day we received an urgent request from our customer, that they asked us to deliver one SL bearing (full complement cylindrical roller bearing) to them in short time, reason was that the bearings delivered from their current supplier were rejected by the...

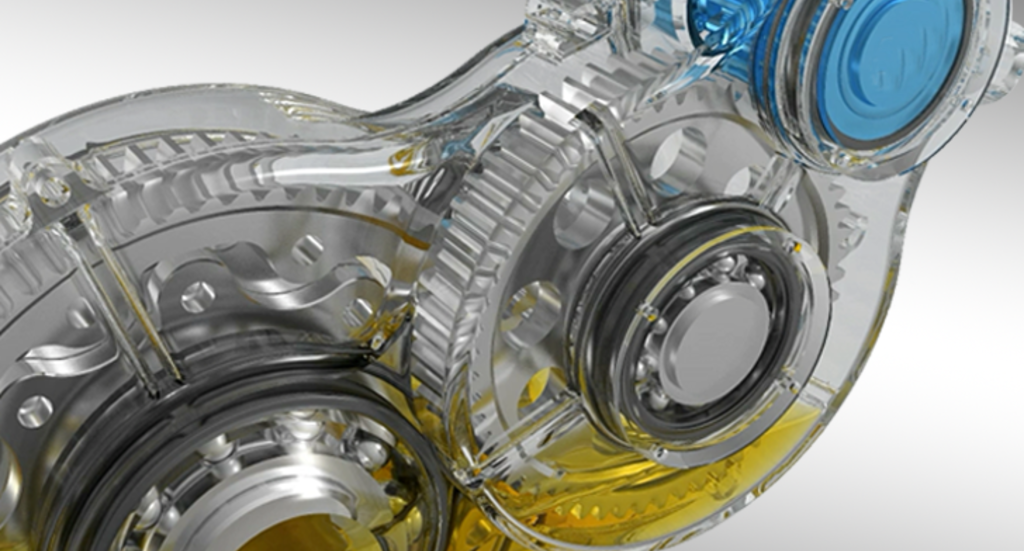

The type of machinery is different, the service conditions of the bearings will be different, and the performance requirements are also different. Generally speaking, there are more than two bearings that would be used on a shaft. In order to facilitate axial positioning, most of the bearings are used as fixed-end bearings, and the rest are used as floating-end bearings. The following table lists the choice of fixed end and floating end...