what full-complement cylindrical roller bearings are, common types of full-complement CRBs, those ones popularly used in the gearbox sector, and the reasons and the key quality control points.

Powder metallurgy (PM) is a technology that uses metal powder or nonmetal powder or its mixture as raw materials to manufacture metal materials, composite materials and various types of products through forming and sintering. Its three core elements are technology, materials and equipment, which are widely used in transportation, machinery, electronics, aerospace and other important industrial fields. It is the most potential and dynamic branch of new materials science.

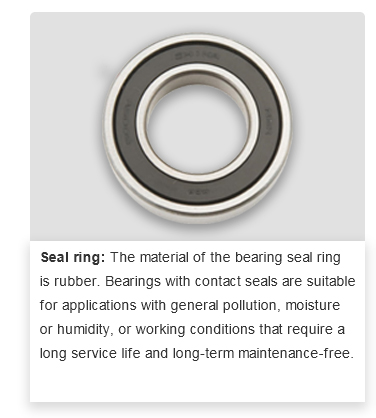

Sealing devices can generally be divided into static seals (fixed seals) and dynamic seals (rotating seals).

The former is called gasket seal, and the latter is called gasket seal.

Sealing is indispensable for bearings. Sealing can not only prevent the leakage of lubricant, but also prevent the invasion of harmful foreign bodies. Otherwise, it will cause the abrasive wear of the bearing raceway, reduce the service life of the bearing, and make the bearing parts corroded by harmful gas and moisture, and accelerate the aging of the lubricant.

These News About Bearing Industry You Must Know in 2021

/..: Standardized rolling bearings with uncoded inner diameters A: Single row angular contact ball bearing with 30° contact angle AC: Single row angular contact ball bearing with 25° contact angle ACD: Single row angular contact ball bearing, optimised internal design, 25° contact angle ADA: Double row full complement cylindrical roller bearing with wide snap ring grooves in outer ring, two inner ring halves held together by U-shaped retaining ring AS: Needle roller bearing with lubrication hole(s) in outer ring. A figure following the AS indicates the number of holes ASR: Needle roller bearing with annular groove and lubrication hole(s) in outer ring. A figure following the ASR indicates the number of holes Axx(x): A combined with a two or three-figure number identifies variants of the standard design, which cannot be identified by generally applicable suffixes B: Deviating or modified internal design with same boundary dimensions. As a rule the significance of the letter is bound to the particular bearing or bearing series Examples: 7210 B Single row angular contact ball bearing with 40° contact angle 32210 B Taper roller bearing with steep contact angle (steeper than 32210) BE: Single row angular contact ball bearing with 40° contact angle and optimised…

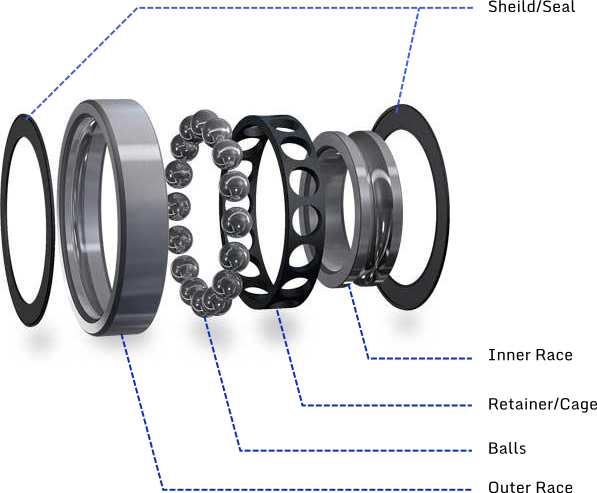

The performance of ball bearings can be critically affected by minute particles. Particles as small as 0.005mm can cause problems. To prevent such problems, we use a class 1,000 clean room throughout our bearing assembly operation. “Keeping bearings clean” is the most important rule of bearing use. Avoid exposing bearings to any environment where particles may be present. Once inside a bearing, such particles can cause raceway scratches, abrasion and shortened life. They can also generate acoustic noise and vibration. We use shields or seals to keep particles out. But there is still a gap between the shield and inner ring of shields and non-contact seals. This gap may permit particle entry. So it is important to observe the following procedures carefully. 1. Keep your bearing handling area as clean as possible. 2. Do not remove the bearings from their packaging until just before use. If you move the bearings to a container, be sure the container is clean. Its lid should be kept closed and it should be cleaned every day to prevent particle accumulation. 3. Never use a bearing that has been 壯陽藥 dropped. It may be brinelled (race track dented). In use, a brinelled bearing will generate…

Gearboxes are used in a very wide range of industrial fields. Thanks to the use of gearboxes, a small rotation force (torque) can be used to produce a much greater rotation force, and a slow rate of revolution can be speeded up. In many industries, the gearbox, which is the equipment that transmits mechanical power, is an essential piece of equipment. This step-up unit is the: heart of a wind turbine transmission in an automobile the reduction gears in a Ferris wheel By supplying bearings for gearboxes such as these in support of their most important function: “revolving,” we believe that it can even be said to be supporting the world. However, because there are many instances where the breakdown of a gearbox would have serious implications, extremely high reliability is demanded. 犀利士 Naturally, we seek to ensure that its designs closely match customer needs, and the company is always aiming to enhance product quality. We supply bearings that offer long life to reduce equipment maintenance costs, can handle high load capacities, and are extremely reliable. We will continue to pool our comprehensive strengths. With environmental issues firmly in its sights, our company will continue product development efforts so that…

At this year’s Hannover Messe in Germany, bearing manufacturer NKE Austria GmbH presents bearings with black oxide finish. The protective layer improves run-in and wear characteristics and protects against environmental effects. Especially in critical applications such as wind turbine gear boxes, black oxide finish is a cost-effective and technically viable means of prolonging the service life and performance of rolling bearings. The black oxide finish forms a protective layer for steel parts. In a multistage chemical process, the surface layer of the treated parts is converted into a 1 to 2 micrometer thin mixed ferrous oxide layer that causes the characteristic black appearance. Black oxide finished bearing components feature a set of special technical characteristics, especially in the case of components that move relative to each other. Multiple protective effects can be achieved if only one functional element (typically the rolling elements) is treated. For best effect, however, all functional surfaces of a rolling element bearing, including the inner and outer ring as well as the rolling elements, should be black oxide finished. Black oxide finishing is already an established method in other industries. NKE uses this technology to further improve the technical properties of rolling bearings. The method has…