Introduction Have you ever heard about ball-bearing units? Or do you want to know about all the basic knowledge associated with ball-bearing units? No matter what the question is, this article will help you know everything that you need to know about ball-bearing units. If you belong to a mechanical industry, you must be aware of the uses of ball bearing units in machine parts available in the market. Ball bearing units, instead of quite important components, aren’t very well known among customers. The reason is that either they don’t know what is it or they don’t have any idea of its importance in their machinery. It is interesting to note that ball bearing units are the most essential and effective components in your machine parts. Ball-bearing units have a higher level of versatility as well as cost-effectiveness. These abilities make them perfect for use in industrial applications. You must be wondering to know about their types, applications, common failures, and key quality points. This article has explained everything perfectly. Want to explore? Continue reading to grab its concept! What Are Ball Bearing Units? There exists an insert bearing mounted in the housing of your ball bearing units. The insert…

what full-complement cylindrical roller bearings are, common types of full-complement CRBs, those ones popularly used in the gearbox sector, and the reasons and the key quality control points.

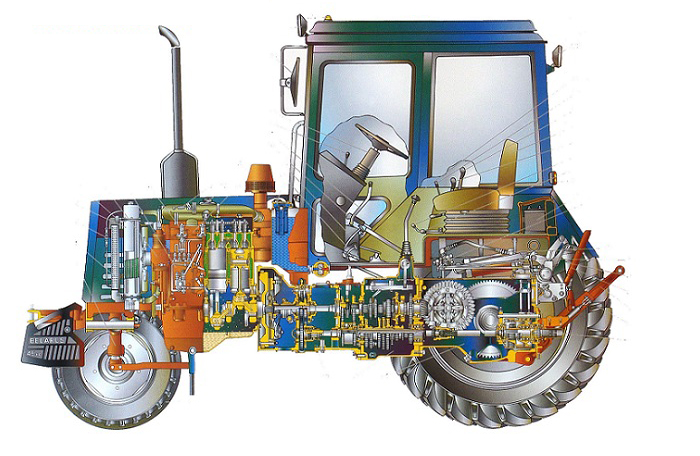

Agricultural engineering involves a wide range of machines, equipment and implements. This ranges from tillage machines, tractors, tedders and balers to powerful harvesting equipment such as forage harvesters or combine harvesters. Even if the machines are very different, the operating conditions are always harsh. In summer, dust and sand place high demands on the bearing seals, whereas during the spring and fall, moisture is a real challenge for farmers. Heavy soils test the mechanical strength of all machine parts to the limit. Constant vibrations and high shocks are loads that occur throughout the entire year. This is why the bearing supports in tillage machines have to be particularly robust. Here we’ll make an introduction about tractor. Although there are many types of agricultural tractors with different structures, they are composed of three parts: engine, chassis and electrical equipment. Following are typical bearing arrangements in agricultural tractors: For further requests on bearings used in agricultural machinery, please make a direct contact with TBB

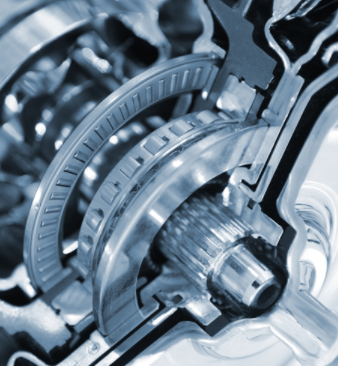

The chassis is the support of construction machinery, which can make the overall unit run in the specified direction at the speed and traction required for operation. According to the characteristics of the traveling system, there are 2 main types of construction machinery chassis: 1.Wheeled chassis, including transmission system, braking system, steering system, traveling system. 2. Tracked chassis, including transmission system, steering system(incl. braking), traveling system, rotary support device(load carrying) Transmission System of Construction Machinery Chassis: The transmission components between the power unit and the driving wheel of construction machinery are collectively referred to as the transmission system. The transmission system is divided into mechanical transmission, hydraulic mechanical transmission, hydraulic transmission and electric transmission. The three main components of transmission system: Gearbox, Differential, Wheel Drive. Gearbox Dual-clutch AT Popular bearing types used: Tapered Roller Bearing Cylindrical Roller Bearing Needle Roller and Cage Assembly 2. AT with hydraulic torque converter Popular bearing types used: Needle Roller and Cage Assembly One-way Clutch Needle Roller Bearing Thrust Needle Roller and Cage Assembly Deep Groove Ball Bearing HK Series Needle Roller Bearing 3. AT with continuously variable transmission Popular bearing types used: Needle Roller and Cage Assembly Tapered Roller Bearing Cylindrical Roller Bearing Deep…

Difference between high-speed and low-speed bearings Many people may misunderstand it, it’s not that the rotation speed of the bearing itself, but its linear speed. Many low speed bearings can reach tens of thousands of revolutions per minute, on the other hand, for some high-speed bearings, the data of rotations per minute maybe only just a few hundred. There are also some other differences between the two. Generally, low-speed bearings have a rougher appearance, and the joints between parts are looser. To ensure its accuracy, the precision of high-speed bearing is generally very smooth on the surface, and the distance between the inner ring and outer ring is minimal, the accuracy is much higher. Many high-speed bearings are also super-precision bearings. It normally use special high speed grease. In terms of material, there is also a slightly difference between high-speed bearing and low-speed bearing. High speed bearings are generally made of very high hardness steel, which can withstand the pressure caused by excessively high speeds. If it’s low, some common materials are used, the requirements for hardness and durability of the material are relatively reduced. What to do if the high-speed bearing is overloaded and hot? 1) In the case…

Bearing Selection Guide The types, structures, and sizes of rolling bearings are diverse. In order to make the mechanical device play the expected performance, it is very important to choose the most suitable bearing. To select a bearing, many factors need to be analyzed. The general sequence is as follows: (1) Understand the operating conditions of mechanical devices and bearings, etc. (2) Clear requirements for bearings (3) Select the type of bearing (4) Select the bearing configuration (5) Select bearing size (6) Select bearing specifications (7) Installation method of selected bearing The location of the bearing, the operating conditions, and the environmental conditions are the prerequisites for choosing a suitable bearing. For this, it is necessary to obtain the following data and information: (1) Function and structure of the mechanical device (2) Where to use the bearing (3) Bearing load (size, direction) (4) Rotation speed (5) Vibration and shock (6) Bearing temperature (ambient temperature, temperature rise) (7) Ambient atmosphere (corrosive, clean, lubricating) How to select the bearing type for your machine? When selecting a bearing type, it is important to fully understand the operating conditions of the bearing. The following table lists the main analysis items:

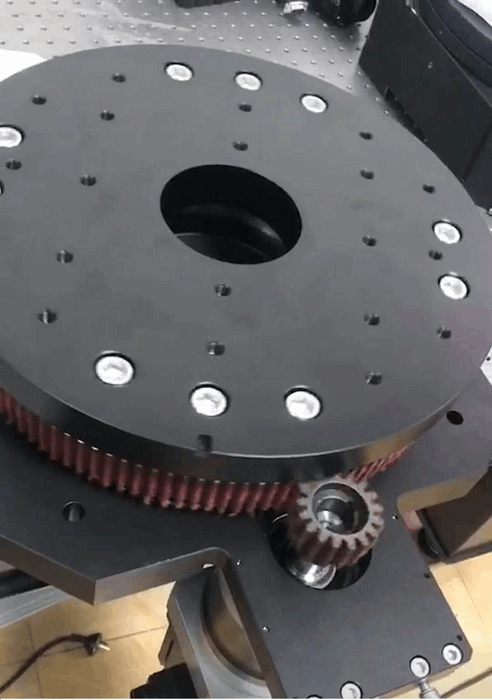

Slewing bearings usually have a diameter ranging from 0.2 to 10 meters. They consist of mounting holes, internal or external ring gears, lubricating oil holes, and sealing devices. The mounting holes are divided into through holes and threaded holes. Different for different industries The slewing bearing has a variety of structural types to meet its requirements, and can meet the needs of the main engine function with different manufacturing accuracy levels. Therefore, the slewing bearing is an indispensable machine on the slewing device of medium and large construction machinery slewing bearing. component. It plays an important role in the machinery industry, construction industry, coal industry and shipbuilding industry. The slewing bearing has toothless type, external tooth type and internal tooth type. The structure types slewing bearing generally include single-volley, double-volley, cross-roller, three-row roller, ball-column combined and other forms, of which single-row ball The slewing bearing has a relatively low cost and excellent overall performance. The double volleyball slewing bearing has certain advantages in service life, strong bearing capacity, small swing resistance, large allowable wear, and strict requirements for the mounting base. Raceway rotation accuracy is low; Crossed roller slewing bearings have high accuracy, long life, and high dynamic load capacity, but have high…

Material Cronidur30ISO Standard: DIN 1.4108Chemical formula: X30CrMoN15-1Advantages: Finer structure, less heat generated, higher permissible contact pressure, much higher fatigue life reliability (10x compared with GCr15 in best case), better corrosion resistance and high temperature resistance Material Ceramic Si3N4Advantages: Excellent tribological properties, lower density to improve the bearing kinematics, lower coefficient of thermal expansion, no magnetism, high current insulation

Bearing in ABEC-7(P4) or ABEC-1(P0) for my application? ●What does Bearing Precision mean? When dealing with rolling bearings, precision is described by tolerance classes which include dimensional accuracy and running accuracy.it is regulated by ISO or other related standards. Dimensional Accuracy includes (the items related to the installation of shaft and outer shell): 1. Allowable deviation (acceptable values) for bore diameter, outer diameter, width and assembled bearing width 2. Bore diameter uniformity as seen in chamfer dimensions 3. Allowable inner ring tapered bore deviation and shape error 4. Average bore diameter variation 5. Outer diameter variation 6. Average outer diameter unevenness 7. Raceway width and height variation (for thrust bearings) Running Accuracy includes (items related to the runout of the rotator): Acceptable values for inner and outer ring radial runout and axial runout Acceptable values for inner ring side runout, and outer ring outer diameter runout Permissible variation of raceway thickness of thrust bearing Permissible deviation and variation of tapered hole Permissible variation of inclination of the outer ring surface Here I attached the comparison table from different countries: The applicable accuracy levels are different according to different types of bearings. The following table shows different types of bearings and their…