In selecting bearings, the most important thing is to fully understand the operating conditions of the bearings.

The main factors to be considered are listed below:

1.Installation space

Bearing can be installed in target equipment

When a shaft is designed, its rigidity and strength are considered essential; therefore, the shaft diameter, i.e., bore diameter, is determined at start.

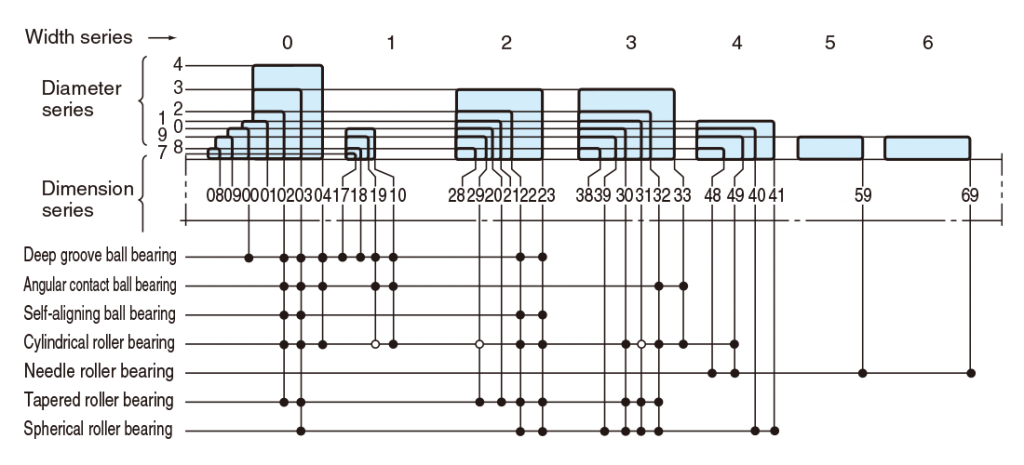

For rolling bearings, since wide variety with different dimensions are available, the most suitable bearing type should be selected.

2.Load

Load magnitude, type and direction which applied

(Load resistance of bearing is specified in terms of the basic load rating, and its value is specified in the bearing specification table.)

Since various types of load are applied to bearings, load magnitude, types (radial or axial) and direction of application (both directions or single direction in the case of axial load), as well as vibration and impact must be considered in order to select the proper bearing.

The following is the general order for radial resistance ;

(deep groove ball bearings < angular contact ball bearings < cylindrical roller bearings < tapered roller bearings < spherical roller bearings)

3.Rational speed

Response to rotational speed of equipment in which bearings will be installed

(The limiting speed for bearing is expressed as allowable speed, and this value is specified in the bearing specification table.)

Since the allowable speed differs greatly depend-ing not only upon bearing type but on bearing size, cage, accuracy, load and lubrication, all factors must be considered in selecting bearings.

In general, the following bearings are the most widely used for high speed operation.

(deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings)

4.Running accuracy

Accurate rotation delivering required performance

(Dimension accuracy and running accuracy of bearings are provided by JIS, etc.)

Performance required differs depending on equipment in which bearings are installed : for instance, machine tool spindles require high running accuracy, gas turbines require high speed rotation, and control equipment requires low friction. In such cases, bearings of tolerance class 5 or higher are required.

The following are the most widely used bearings.

(deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings)

5.Rigidity

Rigidity that delivers the bearing performance required

(When load is applied to a bearing, elastic deformation occurs at the point where its rolling elements contact the raceway surface.

The higher the rigidity that bearings possess, the better they control elastic deformation.)

In machine tool spindles and automobile final drives, bearing rigidity as well as rigidity of equipment itself must be enhanced.

Elastic deformation occurs less in roller bearings than in ball bearings.

Rigidity can be enhanced by providing preload.

This method is suitable for use with angular contact ball bearings and tapered roller bearings.

6. Misalignment (aligning capability)

Operating conditions which cause misalignment (shaft deflection caused by load, inaccuracy of shaft and housing, mounting errors) can affect bearing performance

(Allowable misalignment (in angle) for each bearing type is described in the section before the bearing specification table, to facilitate determination of the self-aligning capability of bearings.)

Internal load caused by excessive misalignment damages bearings. Bearings designed to absorb such misalignment should be selected.

The higher the self-aligning capability that bearings possess, the larger the angular misalignment that can be absorbed. The following is the general order of bearings when comparing allowable angular misalignment :

(cylindrical roller bearings < tapered rollerbearings < deep groove ball bearings, angular contact ball bearings < spherical rollerbearings, self-aligning ball bearings)

7. Mounting and dismounting

Methods and frequency of mounting and dismounting required for periodic inspection

Cylindrical roller bearings, needle roller bearings and tapered roller bearings, with separable inner and outer rings, are recommended for applications in which mounting and dismounting is conducted frequently.

Use of sleeve eases the mounting of self-aligning ball bearings and spherical roller bearings with tapered bore.

Koyo

No Comments