Key Factors of Electric Motor Bearing Design

–Outline dimensions

–Load size and direction

–Speed requirements, constant/variable/high

–Material of motor shaft and housing

–Power take-off transmission form

–Motor installation form

–Vibration level requirements

–Noise level requirements

–Temperature requirements

–Bearing life

–Lubrication form

–Maintenance

–Condition monitoring

–Sealing and protection

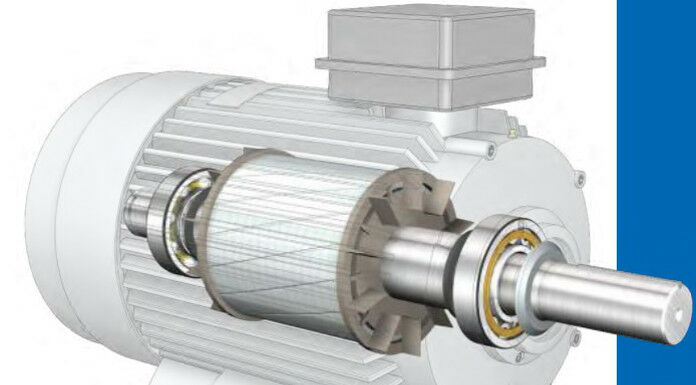

Common Configuration of Electric Motor Bearing

–Horizontal Motor

1. DGBB+DGBB

Cross positioning configuration, suitable for small and medium-sized motors, low maintenance requirements, axial guidance is not a key parameter, non positioning bearings have spring preloading

2. Sealed DGBB + CRB

Suitable for large motors, with heavy load on the drive side and axial expansion inside the bearing

3. CRB + A pair of Angular Contact Ball Bearing Face to Face

For motors with bidirectional axial load and heavy radial load, or for occasions with strict requirements on axial displacement

4. DGBB + A pair of Angular Contact Ball Bearing Face to Face

It is used for small motors with axial load and moderate radial load, or for occasions with strict requirements on axial movement. Deep groove ball bearing is with spring preload

5. CRB + CRB & DGBB

For large motors. The deep groove ball bearing is free in radial direction, and the O-ring is used to prevent the outer ring from rotating

6. SRB + SRB

For extra large motors and heavy load occasion

–Vertical Motor

1. DGBB + DGBB

For small and medium-sized motors, the floating end of the upper bearing is added with pre tightening spring on the end face, and the lower bearing is the fixed end (output end), which bears two smaller axial forces

2. Angular Contact Ball Bearing + DGBB

For large motor, the upper part is angular contact ball bearing, which bears medium size one-way axial force, the lower deep groove ball bearing is floating end (output end), and pre tightening spring is added on the end face

3. A pair of Angular Contact Ball Bearings Tandem Position + DGBB

For large motors, the upper part is equipped with two angular contact ball bearings in tandem position, bearing large one-way axial force, the lower deep groove ball bearing is floating end (output end), and the end surface is added with pre tightening spring

4. A pair of Angular Contact Ball Bearing Face to Face + DGBB

For large motor, it can bear two-way and medium axial load. The upper part (fixed end) is equipped with matched angular contact ball bearing, bearing two-way axial force. The lower deep groove ball bearing is floating end (output end), and the end face is added with pre tightening spring

5. CRB + Trust Spherical Roller Bearing

For large motors, it can bear large unidirectional axial load. The upper part (floating end) is cylindrical roller bearing, which can absorb axial floating and the lower thrust spherical roller bearing (output end)

TBB Motor Bearing Characteristics

1. Motor Deep Groove Ball Bearing

–Higher manufacturing accuracy level

–Up to V2 vibration level and can be upgraded to V3 or V4 as required

–Suitable for high-speed, silent, high-precision applications

–Variable types of grease can be provided according to requests

2. Spherical Roller Bearing

–Multiple cage guide options

–Higher grade raw materials

–High manufacturing accuracy, high rotation accuracy

–Stricker roller grouping

–Optimized internal design to have higher carrying capacity

–SRB with seals can be provided according to requests

3. Cylindrical Roller Bearing

–Various cage structures and materials are available

–Higher grade raw materials

–High manufacturing accuracy, high rotation accuracy

–Stricker roller grouping

–Optimized internal design to have higher carrying capacity

–Can be used in high speed condition

4. Angular Contact Ball Bearing

–Various cage structures and materials are available

–Higher grade raw materials

–High manufacturing accuracy, high rotation accuracy

–Stricker ball grouping

–Optimized internal design to have higher carrying capacity

–Universal matched angular contact ball bearings can be provided

5 Comments

Simple and clear! Excellent!

Very useful content, I collect it

A CARB bearing is another solution for replacing CRB or SRB. But not for both side, only for free side.

yeah, that’s right~

Nice Article Thanks for share this.