Introduction

Have you ever heard about ball-bearing units? Or do you want to know about all the basic knowledge associated with ball-bearing units? No matter what the question is, this article will help you know everything that you need to know about ball-bearing units. If you belong to a mechanical industry, you must be aware of the uses of ball bearing units in machine parts available in the market.

Ball bearing units, instead of quite important components, aren’t very well known among customers. The reason is that either they don’t know what is it or they don’t have any idea of its importance in their machinery. It is interesting to note that ball bearing units are the most essential and effective components in your machine parts.

Ball-bearing units have a higher level of versatility as well as cost-effectiveness. These abilities make them perfect for use in industrial applications. You must be wondering to know about their types, applications, common failures, and key quality points. This article has explained everything perfectly. Want to explore? Continue reading to grab its concept!

What Are Ball Bearing Units?

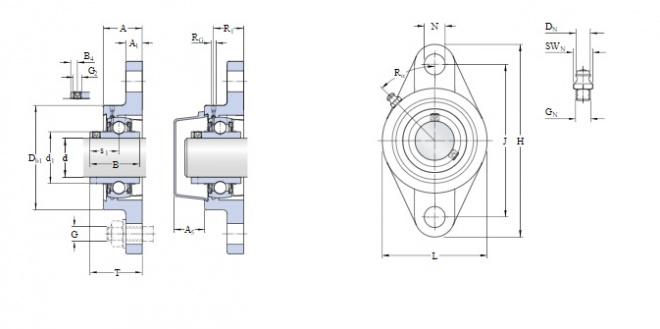

There exists an insert bearing mounted in the housing of your ball bearing units. The insert bearing consists of the deep groove ball bearing. Furthermore, it has a surface that is sphered outside. An extended inner ring is also included in this system. All these parts together include a process that helps to lock the unit into the shaft.

Note that the housings have a concave bore. It is interesting to note that different manufacturers or suppliers can provide you with different locking methods, housing shapes, bearings, and seals. It is also important that your ball-bearing units must follow the particular standards of manufacturing according to your country.

Warning:

When you use these units in a design where the environment, safety, and health are at risk, you should contact the manufacturing facility or company while designing.

Some common benefits and features of ball bearing units are listed below:

✓Quick locking on shaft

✓Efficient locking options for low vibration and high speeds.

✓Ready to mount

✓A large variety is available for housing shapes, locking methods, and housing materials.

✓Sealed and lubricated bearings

What Are Applications Of Ball Bearing Units?

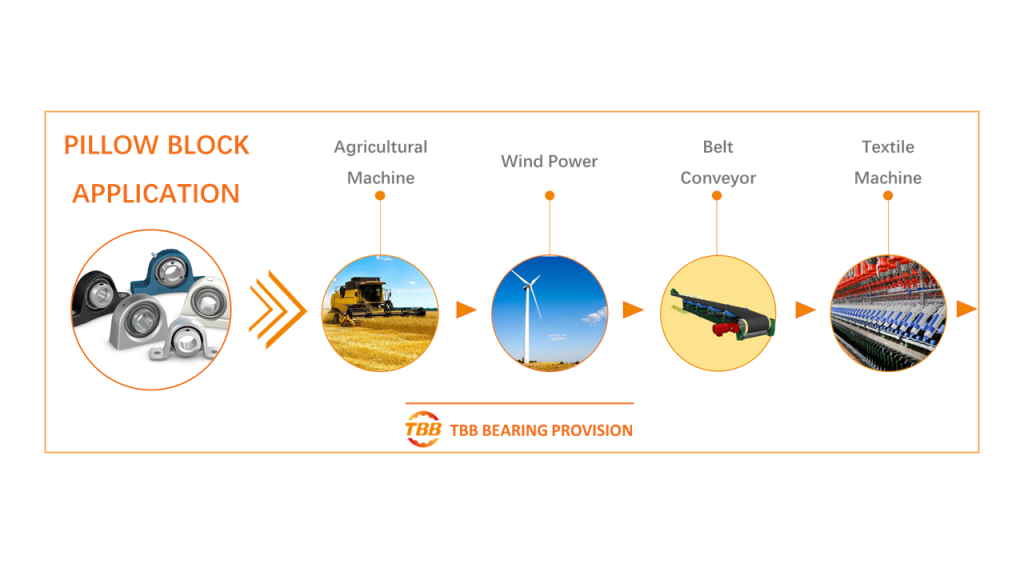

Ball bearing units are most commonly used for industrial applications. The applications of ball bearing units also vary with their varying types. Most people largely use ball bearing units in general machinery and transmission equipment. These bearing units are also used for roll support and a conveyance or carrier equipment.

What Are Common Types Of Ball Bearing Units?

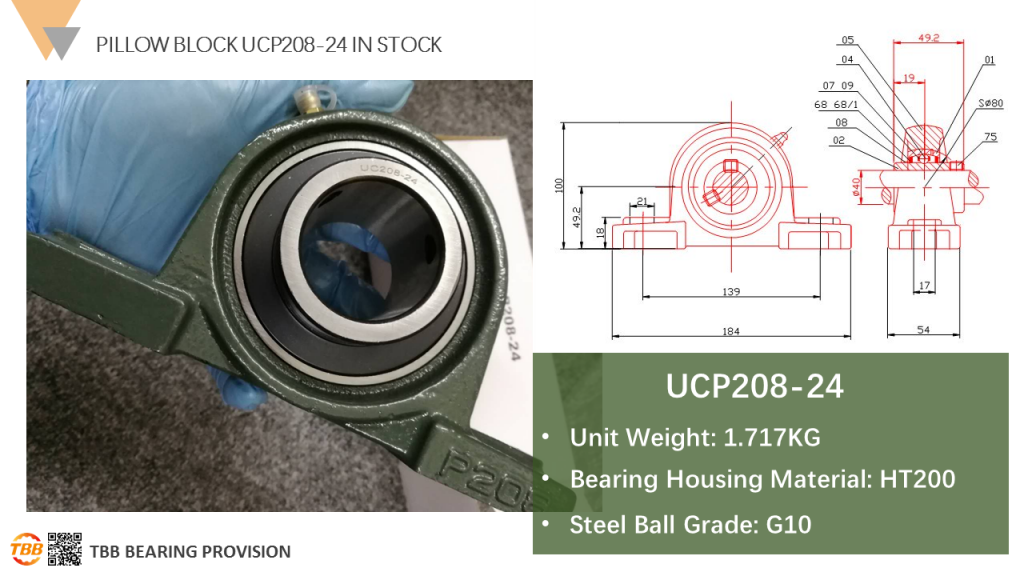

Pillow Blocks

These bearing units are also known as plumber blocks. The pillow blocks bearing units are the most common ball bearing units. It features a bearing mounted in rigid and simple housing. You can see most of its applications in general machinery parts as well as transmission equipment.

Features

✅You can ask your supplier to give you this bearing unit with a customizable material. The companies may have different materials available based on the standards and requirements of customers.

✅It also exists in various types and shapes of housing. You can choose the one that perfectly matches your machine requirements.

Applications

✅Extensively used for roll support and carrier equipment.

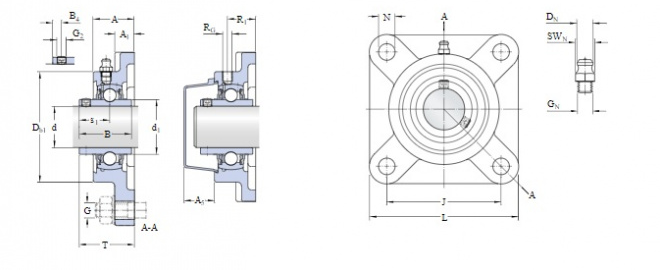

Square Flanged Units

These types of ball bearing units consist of square flangs that you can easily attach to a machine with four bolts. Since they have a simple mounting face, they are widely used across the globe. Note that you can get them designed according to the outer ring of bearings.

Features

✅Simple and easy to use

✅Customizable designs

✅Exists in various types

Applications

✅It is most widely used in conveyance equipment and other roll support and general applications.

Oval Flanged Units

This type of bearing unit features a diamond-shaped flange. It allows easy mounting to the side walls or machine base with two bolts. You can see its usage in machine parts where the distance between shafts and the mounting space is small. In simple words, these bearings are most suitable for places where there is no horizontal frame.

Features

✅Reduce misalignment

✅Save time

✅Easily mountable

✅Customizable

✅Several types and designs

Applications

✅As mentioned earlier, these bearing units are most commonly used in parts where there is limited mounting space. Moreover, these are also used extensively for carrier equipment or roll support just like other ball bearing units.

What Are Key Quality Control Points Of Ball Bearing Units?

You can determine the key quality control points of ball-bearing units from several factors. However, there are a few common factors and things that help to make this process very simple. As you know that ball bearing units are extensively used in multiple industries and various machine parts. These units are important because they help to carry heavy loads.

Now suppose that your ball-bearing units aren’t even capable of carrying loads, you will definitely consider them low-quality ball-bearing units. This case happens only when your ball-bearing units are composed of low-quality material. The quality of your ball-bearing units depends upon the material that is used to manufacture them.

There are multiple raw materials used for the production of ball-bearing units. You have to use a particular grade for a particular material. For example, if you choose grey cast iron then HT200 is a good grade of grey cast iron. On the other hand, HT130 is known as low-quality grey cast iron. Therefore, it is recommended to use HT200 or HT170 for high-quality units.

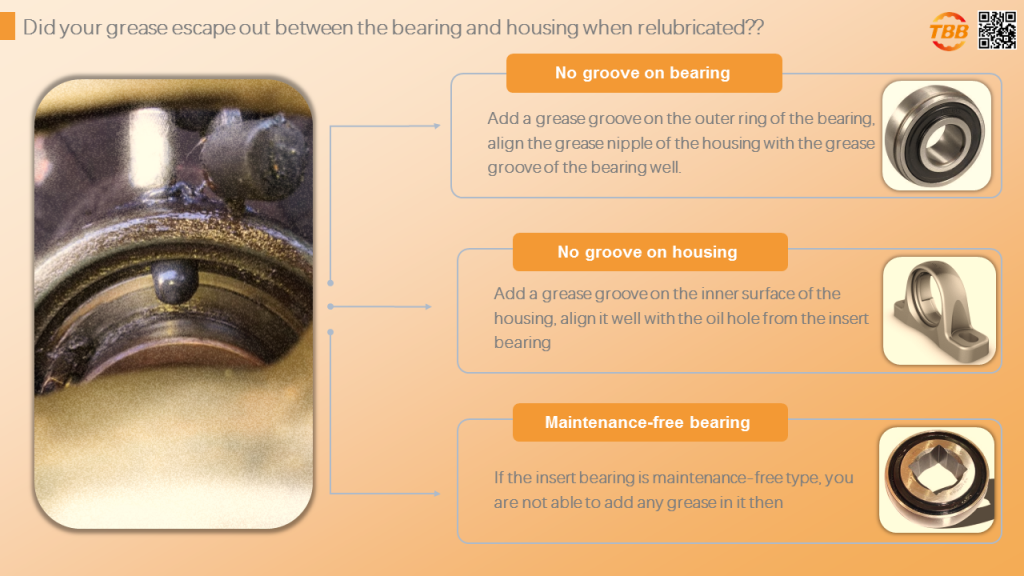

What Are Common Failures In Ball Bearing Units?

The common failures of ball bearing units occur mostly due to low-quality manufacturing material. The re-lubrication capacity and housing materials having low strengths are the common failures. If your ball-bearing units are having these failures, they will not be able to afford heavier loads.

Make sure your supplier gives you a ball-bearing unit manufactured with high-quality material.

Conclusion

Ball bearing units play an important roll in proper functioning of your machinery. It is you who need to decide which quality and which supplier you should choose. If you are looking for a reliable and trustable supplier from China, look no further. You can Contact Us now. We provide maximum customer satisfaction through our skills and experience.

We also prefer the customer feedback and give the best after-sale and pre-sale services.

No Comments