Introduction If you belong to the agricultural sector, you must be aware of the importance to use right bearings in agricultural sectors so that the agricultural equipment must be able to withsta......

...

Bearing packaging is an important step in bearing export. Improper packaging will bring many problems to bearing products and customers, resulting in unnecessary losses and trouble. Case example: Many......

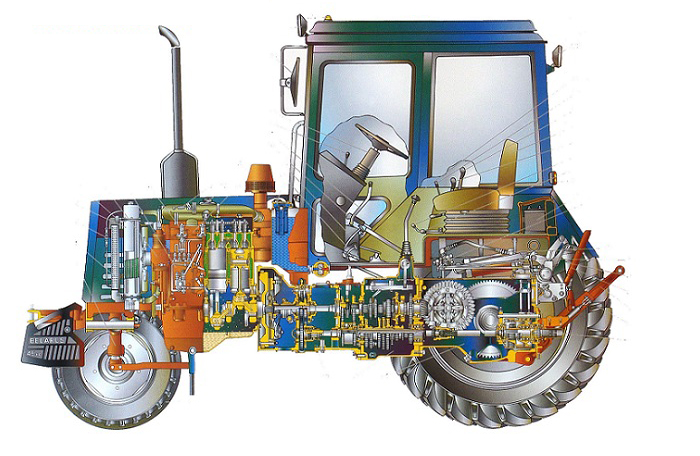

Agricultural engineering involves a wide range of machines, equipment and implements. This ranges from tillage machines, tractors, tedders and balers to powerful harvesting equipment such as forage ha......

The chassis is the support of construction machinery, which can make the overall unit run in the specified direction at the speed and traction required for operation. According to the characteristics ......

Difference between high-speed and low-speed bearings Many people may misunderstand it, it’s not that the rotation speed of the bearing itself, but its linear speed. Many low speed bearings can r......

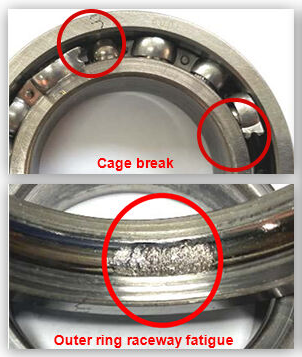

When bearings are 100% inspected with all dimensions on approved drawings based on GB or ISO standard, we confirm bearings are qualified. Here we would like to share you with a case: One day we receiv......

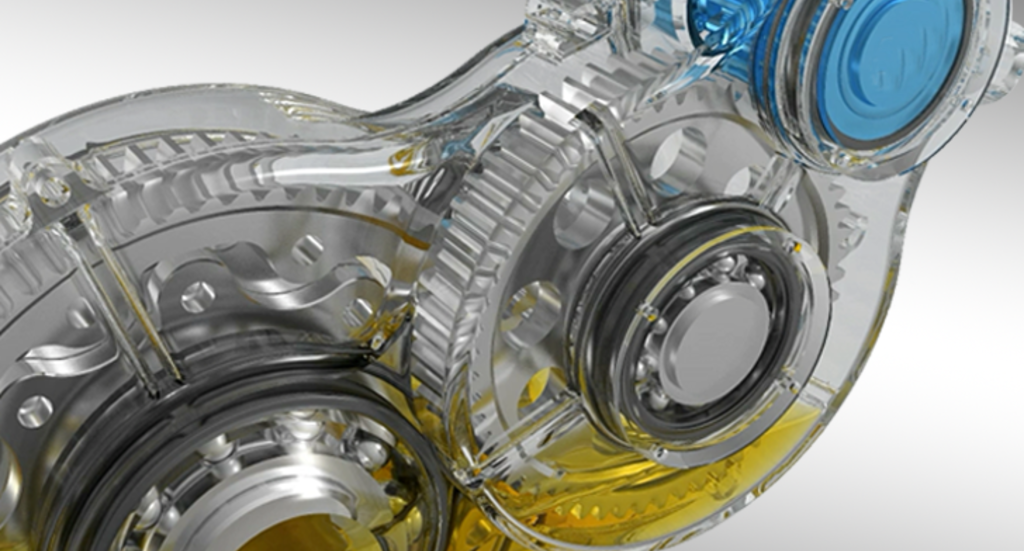

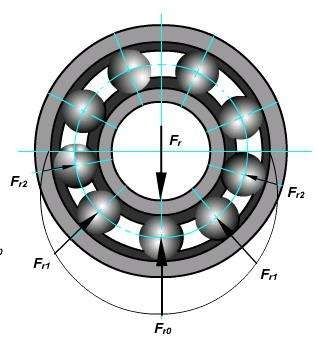

The type of machinery is different, the service conditions of the bearings will be different, and the performance requirements are also different. Generally speaking, there are more than two bearings ......

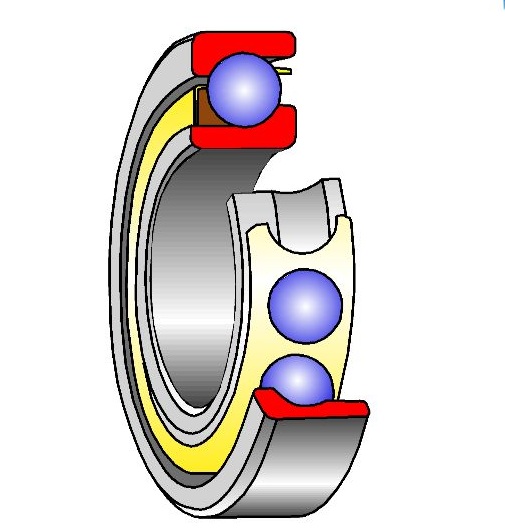

Bearing Selection Guide The types, structures, and sizes of rolling bearings are diverse. In order to make the mechanical device play the expected performance, it is very important to choose the most ......

Have you ever noticed the types of cage guidance of your bearings? Basically, there are 3 types: outer-ring-rib guidance, inner-ring-rib guidance, and rolling-element guidance. Unfortunately, big par......

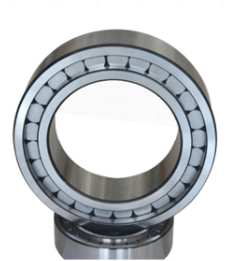

Full complement cylindrical roller bearings are capable of carrying higher radial loads than bearings that utilize a cage and roller design....

There are many types of bearing materials, among which stainless steel is probably one of the most commonly used bearing materials. Compared with ordinary bearing steel (Chrome steel GCr15/100 Cr6/SUJ......

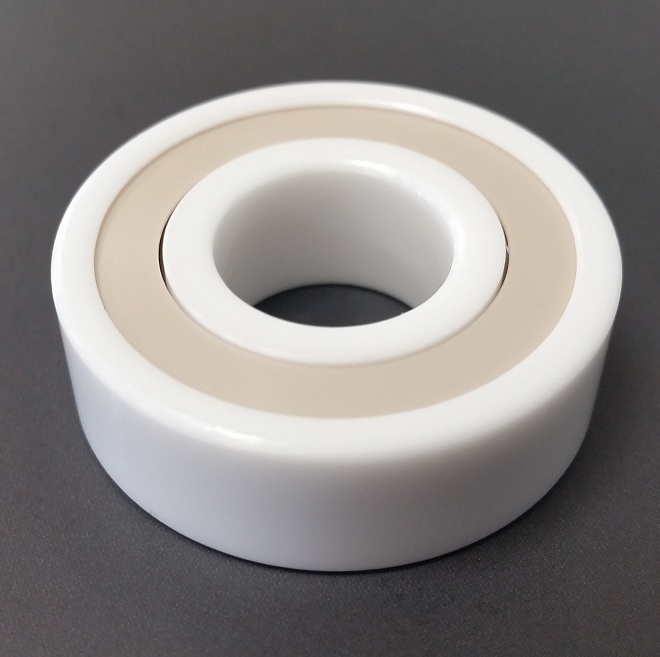

Full ceramic bearings have the characteristics of magnetoelectric insulation, wear resistance, corrosion resistance, oil-free self-lubrication, high temperature and cold resistance, which can be used ......

Apprehensions about a steel shortage in China are unfounded and the recent price increases have largely been a result of short-term market-related factors, experts said. “There is no shortage of......

With the development of mechanical manufacturing industry towards high precision and high speed, the application range of bearings is more and more wide, and the performance requirements of bearings a......

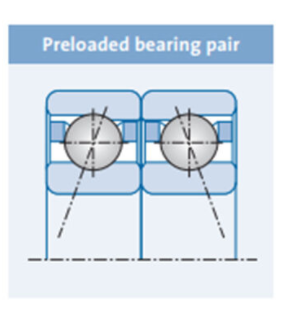

Bearing is an important part of mechanical rotation, and its stiffness and working temperature will directly affect the bearing efficiency on the mechanical operation. In order to provide the rotation......

TBB family is getting bigger and bigger. The only constant 犀利士 is the smile on our faces, and sincerity to our clients....

Since the second half of 2020, affected by multiple factors, bearing raw materials have increased significantly. At the end of the year, the price of bearing steel has increased by nearly 30%. Bearing......

Powder metallurgy (PM) is a technology that uses metal powder or nonmetal powder or its mixture as raw materials to manufacture metal materials, composite materials and various types of products through forming and sintering. Its three core elements are technology, materials and equipment, which are widely used in transportation, machinery, electronics, aerospace and other important industrial fields. It is the most potential and dynami...

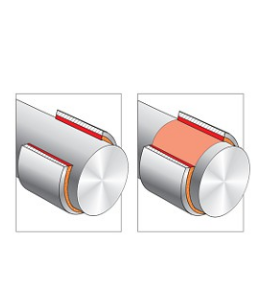

Sealing devices can generally be divided into static seals (fixed seals) and dynamic seals (rotating seals). The former is called gasket seal, and the latter is called gasket seal....

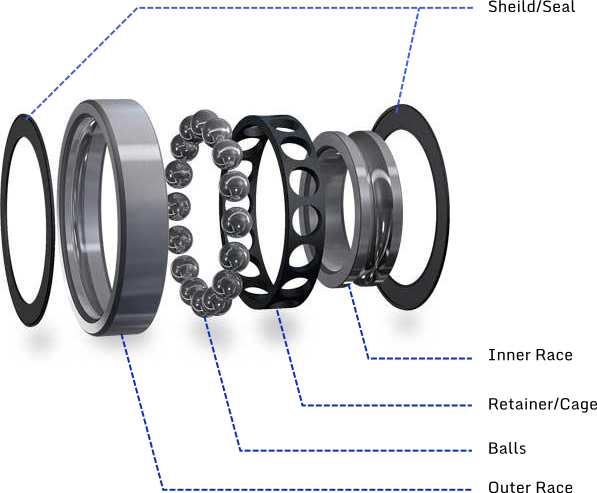

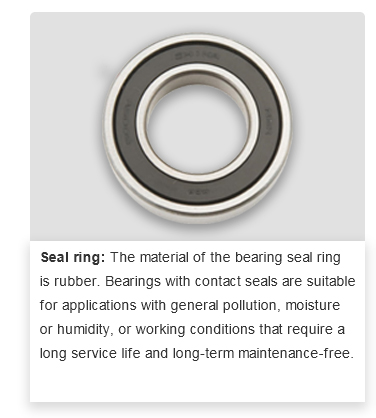

Sealing is indispensable for bearings. Sealing can not only prevent the leakage of lubricant, but also prevent the invasion of harmful foreign bodies. Otherwise, it will cause the abrasive wear of the bearing raceway, reduce the service life of the bearing, and make the bearing parts corroded by harmful gas and moisture, and accelerate the aging of the lubricant. ...

These News About Bearing Industry You Must Know in 2021...

The number of electric and hybrid cars on the road is on the rise leading to innovation in the bearings used on the production line. Nobody could have predicted the huge number of electric and hybrid cars on the road worldwide today....

“Maintenance-free” is an industry-wide term used to describe plain bearings and rod ends with self-lubricating sliding contact surface combinations. These so-called maintenance-free bearings and rod ends offer a number of advantages for OEMs and end users alike. These advantages, which include minimal maintenance and reduced lubricant consumption, quickly compensate for the difference in the initial purchase price. And of course, t...

Here are some examples of applications in which spherical roller bearings might be used: Vibration Screen Bearing, Wind turbine bearings, Papermaking mills bearings, Continuous Caster bearings & etc....

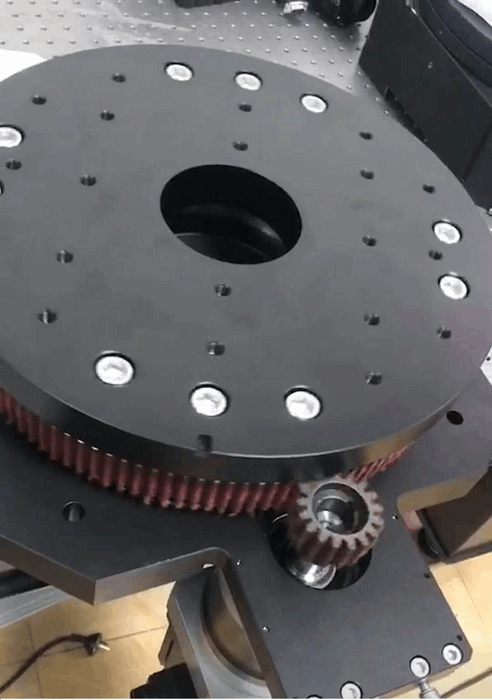

Here you can find some application cases for slewing bearings used in indoor EVs...

Spherical Roller Bearings have many different structures, such as CC type, CA type, E type from SKF and MA type, MB type, E1 type from FAG. Now let me give you a detailed introduction of the difference between these designs....

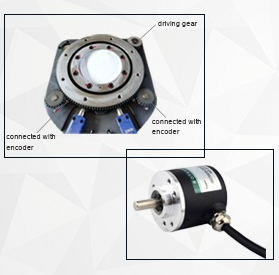

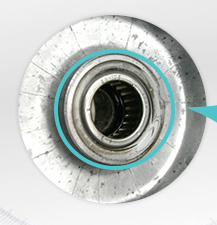

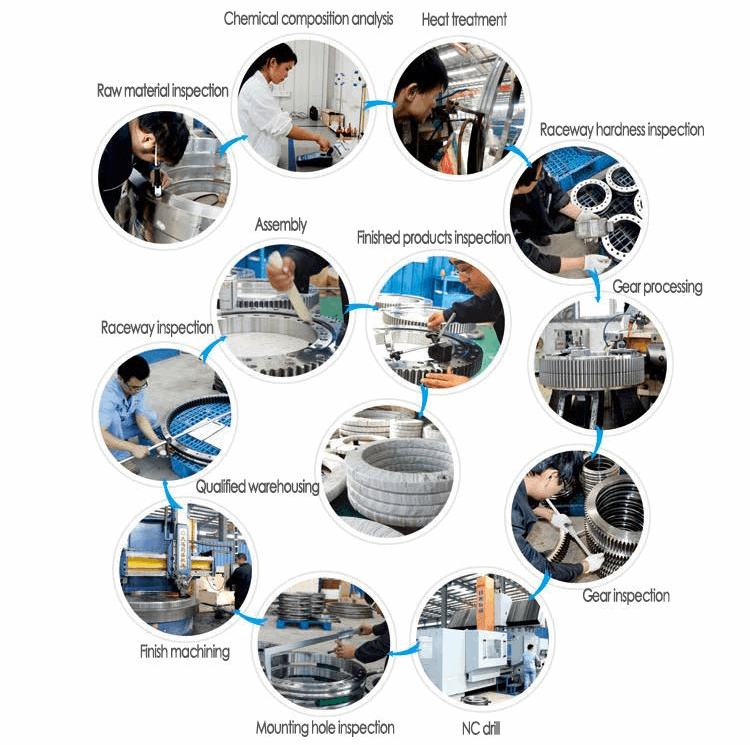

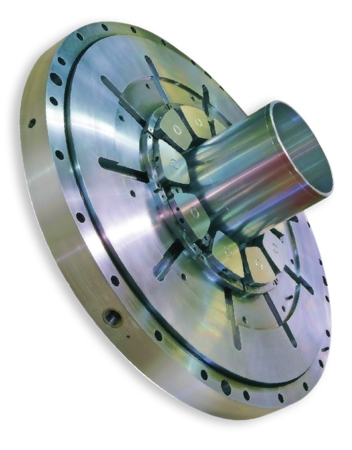

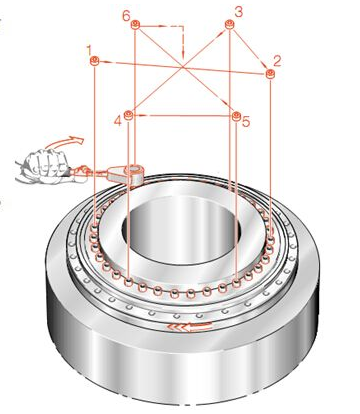

Slewing bearings usually have a diameter ranging from 0.2 to 10 meters. They consist of mounting holes, internal or external ring gears, lubricating oil holes, and sealing devices. The mounting holes ......

Slewing Bearing, also known as slewing ring bearing, turntable bearing, slewing ring, etc, is widely used in modern industries. Types of Slewing Bearing Single-row ball type (01 series, HS series, Q s......

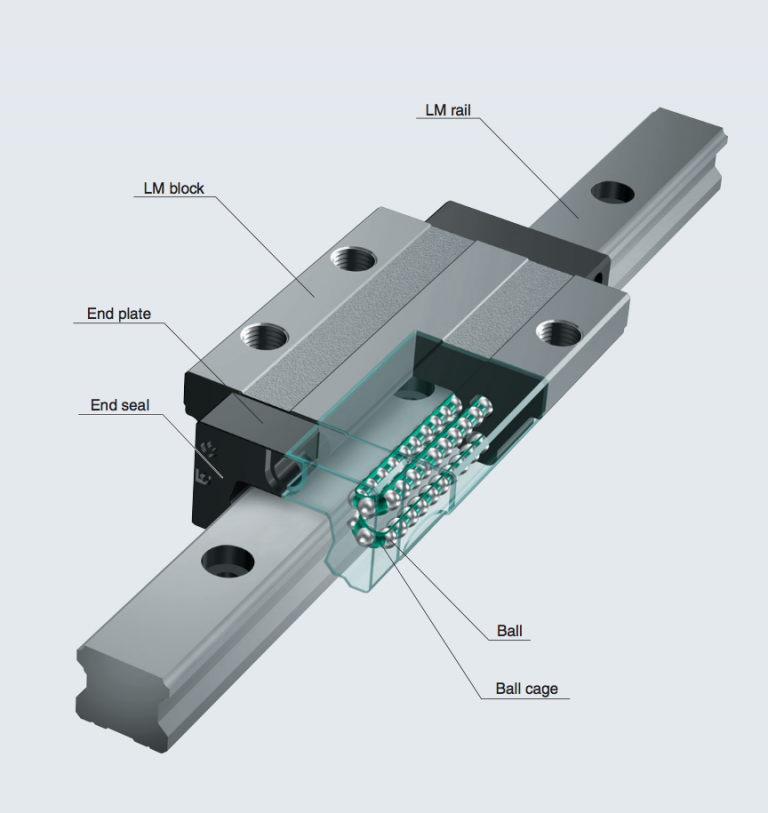

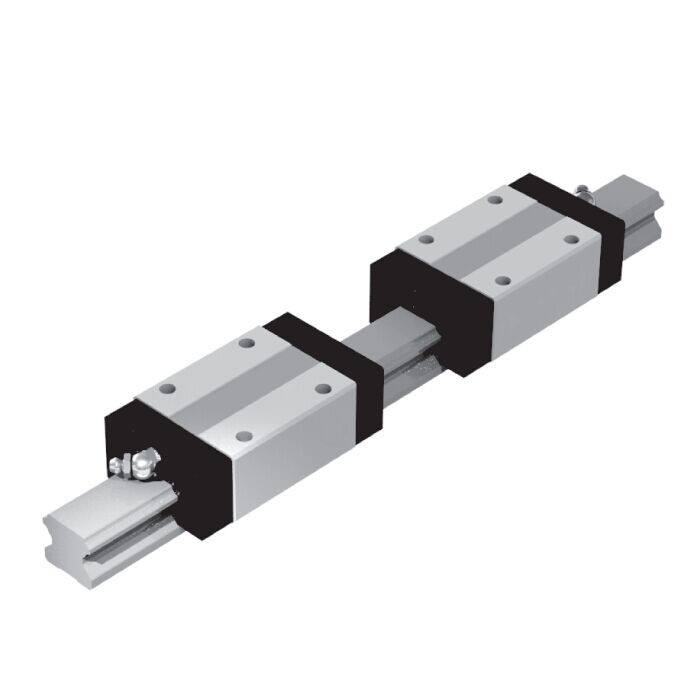

Its construction is simple and cost-effective. The N/O linear guideway assumes the task of being the lateral linear guideway for the table. As the surface guideway is adjusted level with the N/O, the ......

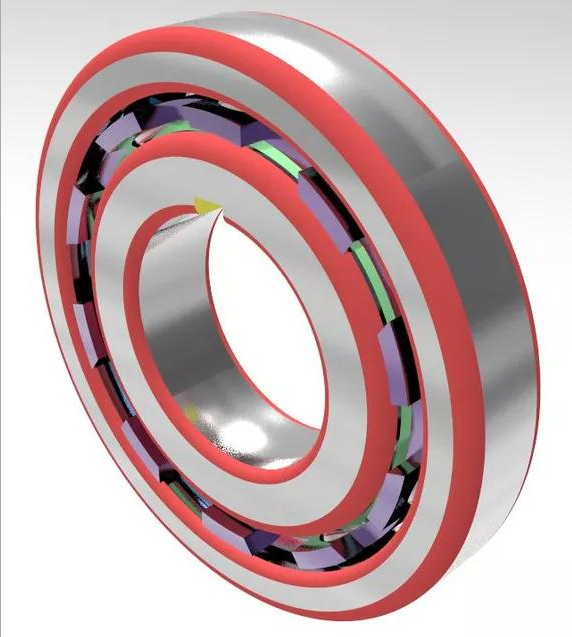

The majority of angular contact bearings use phenolic type cages and these are exceptional good for a wide range of conditions and particularly for high-speed since they are outer ring located. Howeve......

No one knows who invented the planetary gearbox, but it has been in use since the 15th century.Planetary Gearboxes is an old mechanics fundamental that is still being used for new eading innovative te......

/..: Standardized rolling bearings with uncoded inner diameters A: Single row angular contact ball bearing with 30° contact angle AC: Single row angular contact ball bearing with 25° contact angle ACD......

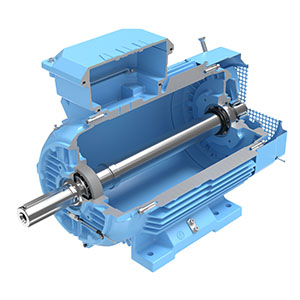

Key Factors of Electric Motor Bearing Design –Outline dimensions–Load size and direction–Speed requirements, constant/variable/high–Material of motor shaft and housing–P......

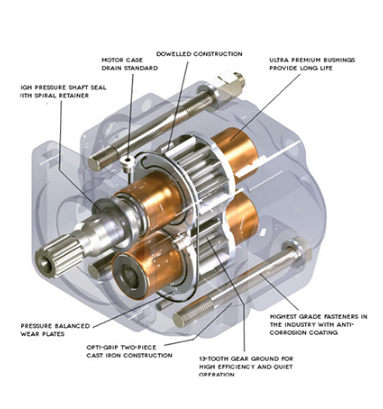

From the elevator you take at work to the dump truck you see rolling by on the street, hydraulics are everywhere. But hydraulic machines are nothing without their hydraulic pumps.The hydraulic pump is......

I was once a piece of iron Coming through a great deal of difficulties Smelting from iron ore Until the billet is formed Continuously quenching from lots of processes Built me an indomitable and undau......

Design Variants To allow the bearings to accept the maximum number of balls, four point contact ball bearings are designed with split inner ring or with split outer ring so these bearings have two bas......

NSK has developed a new ultra-high-speed bearing ideal for electric vehicles, including battery electric, hybrid, and other new energy vehicles. The new bearing enables electric motors to operate at h......

Size from 2mm to 6m Bearings vary in sizes. The smallest “miniature bearing” in the world is with ID 0.6mm× OD 2.0mm× Thickness 0.8mm, which is used in micro motor. The large-size bearing,......

With the wide application of PWM and IGBT in motor, the problems caused by electromagnetic damage such as electric corrosion of bearing are more and more prominent. What causes electromagnetic damage ......

A casual visitor was called Nove壯陽藥 l Coronavirus when we were preparing to celebrate the Spring Festival in January 2020. Because of it, billions of people in our country could not go out, the malls......

What is the preload of crossed roller bearings? Generally, rolling bearings have a certain clearance under working conditions. However, in order to achieve a specific purpose, when the cross roller be......

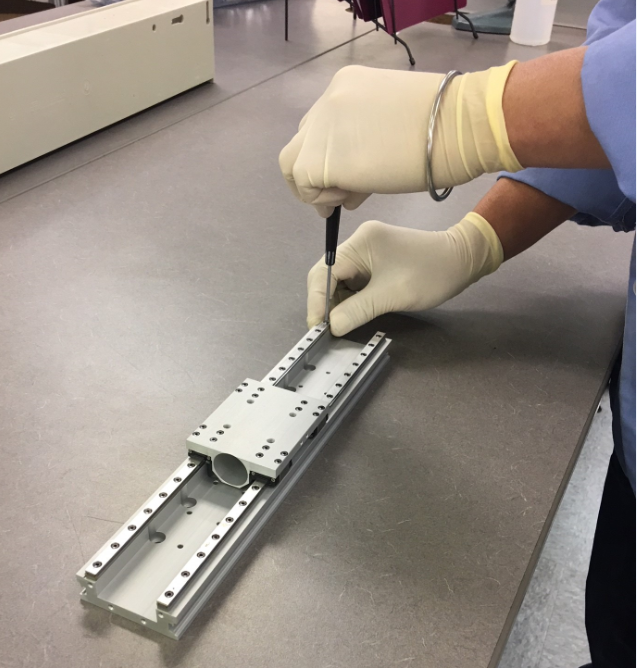

Since bearings are metallic products they rust easily. So their treatment requires certain precautions. 1. When handling bearings, use finger caps, pincers or gloves that do not generate cotton fibers......

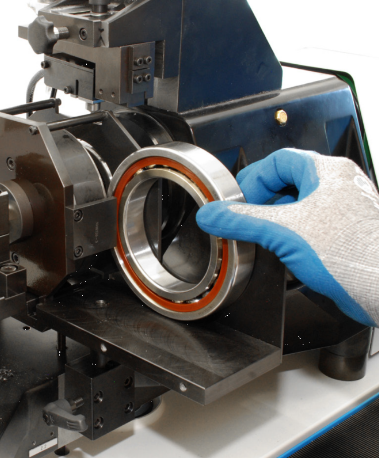

The performance of ball bearings can be critically affected by minute particles. Particles as small as 0.005mm can cause problems. To prevent such problems, we use a class 1,000 clean room throughout ......

Although 2019 was a tough year, TBB have made a lot of achievements with our efforts. We hope in 2020 TBB will win customers’ heart with TBB professionalism, and make greater achievements. In the comi......

After offering we heard many times voice of “Your price is too high” or “Our current price is 50% lower than yours ” …You have explained to customer that how good quality your product is, showed......

5 Reasons to Choose TBB Needle Roller Bearing 1. Years of focusing on bearing, quality guaranteed Estabilished for many years since 1998 and is a p壯陽藥 rofessional supplier of bearings With an a......

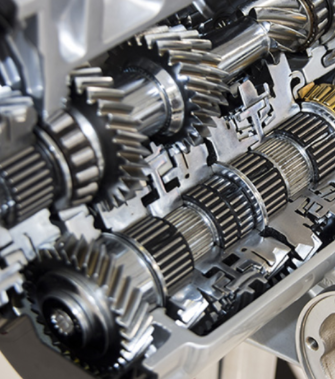

Gearboxes are used in a very wide range of industrial fields. Thanks to the use of gearboxes, a small rotation force (torque) can be used to produce a much greater rotation force, and a slow rate of r......

At this year’s Hannover Messe in Germany, bearing manufacturer NKE Austria GmbH presents bearings with black oxide finish. The protective layer improves run-in and wear characteristics and protects ag......

TBB drawn cup needle roller bearings is formed with thin steel plate through precision punching with very sectional height and big load capacity. This kind of bearings are especially applicable to the......

Material Cronidur30ISO Standard: DIN 1.4108Chemical formula: X30CrMoN15-1Advantages: Finer structure, less heat generated, higher permissible contact pressure, much higher fatigue life reliability (10......

A GROWING NUMBER OF “BARGAIN” BEARINGS&犀利士 nbsp;are being brought into the Heavy Duty Truck and Trailer marketplace by bearing brokers whose primary emphasis is on price. They ignore......

Wheel hub problems are often discovered while ruling out other sources for the squealing and grinding sounds coming from that area of the vehicle or the gradually increasing vibration noticed by the d......

Stainless steel and chrome steel are normally corrosion-resistant, not easy to rust. However, improper storage or handling at high humidity, condensation environment will reduce bearing life. How does......

The manufacturing of metal parts and components is so significant to any economic marketplace, typically, the machine tool industry is utilizing the latest technological advances in manufacturing proc......

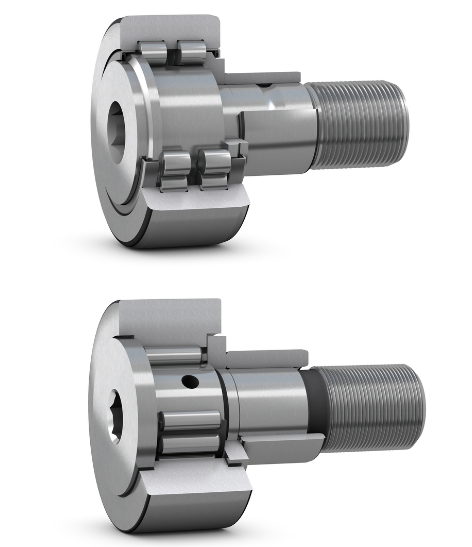

TBB Track Roller is a bearing unit composed of machined thick-wall outer ring, needle rollers or cylindrical roller sets, or cage guidance or full complement needle roller, inner ring or bolt and seal......

Whether you use cam follower bearings for cam followers, or for track, guide, or support rollers, their performance depends largely on the type you select. Important factors include loads, speeds, mis......

From 2009 to 2019, it has been 10 years since TBB Shanghai office estabilished.With 10 years growth, no matter wind or rain, the way we go together, the warmth hidden in the bottom of every TBB member......

Needle bearings are roller bearings with rollers that have high length-to diameter ratios. They are used in farm and construction equipment, automotive transmissions, small gasoline engines, gear pump......

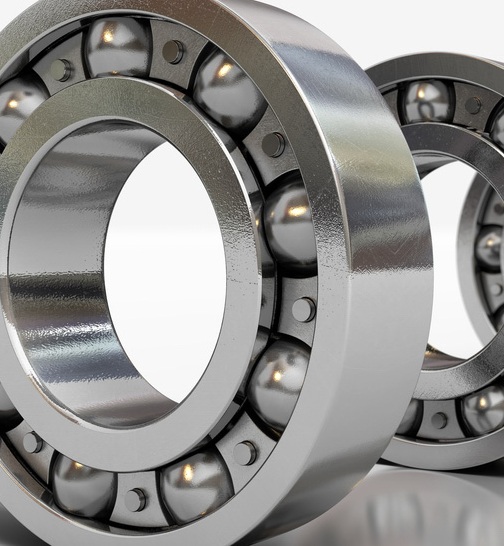

Most rolling-element bearings are either ball or roller bearings. The roller bearing family consists basically of cylindrical, tapered, spherical, and needle bearings. Needle roller bearings are the s......

If you are a cyclist looking to make your bike lighter and help you boost your cycling performance, easily make it possible by upgrading to Ceramic/Hybrid Bearings. TBB Ceramic and Hybrid bearings are......

When bearing steels are in their soft (unhardened) state, metallurgists refer to their structure as being in the pearlite state. In order to harden the steel it must be heated to a very high temperatu......

Self-lubricating bushings are used where the bearing must operate without lubricant or with marginal lubricant. Our focus is on ensuring that the bearing gives the best performance and the longest lif......

In our previous blog entry, we examined static and dynamic load ratings for spherical plain bearings. This week, we continue our look into this bearing segment with some further information on the ope......

Dynamic and static load ratings for spherical plain bearings are important for understanding the life of a bearing, but what do each specify? Read on to learn more about these important classification......

We have assembled a wide variety of frequently asked questions (FAQs) about bearings (e.g. ball bearings, roller bearings, plain bearings, linear bearings) and bearing related products (and bearing se......

1) High carbon chromium bearing steel High carbon chromium bearing steel specified in JIS is used as a general material in bearing rings (inner rings, outer rings) and rolling elements (balls, rollers......

Since the characteristics of materials used for cages greatly influence the performance and reliability of rolling bearings, the choice of materials is of great importance. It is necessary to select c......

In shipping bearings, since they are covered with proper anti-corrosion oil and are wrapped in antitarnish paper, the quality of the bearings is guaranteed as long as the wrapping paper is not damaged......

Periodic and thorough maintenance and inspection are indispensable to drawing full performance from bearings and lengthening their useful life. Besides, prevention of accidents and down time by early ......

It is important for enhancing productivity and profitability, as well as for accident prevention that abnormalities in bearings are detected during operation.Representative detection methods are descr......

In selecting bearings, the most important thing is to fully understand the operating conditions of the bearings. The main factors to be considered are listed below: 1.Installation space Bearing can be......

Bearings with diameters between 36 and 169 in. typically cost a lot and have long lead times, forcing end users to keep spare bearings on hand or face extensive downtime should a bearing fail. Therefo......

Massive rotors in hydroelectric generators, large ball mills, rolling mills, large electric motors, and steam and gas-turbine generators normally operate with great efficiency on oil films in sleeve a......

Caged balls offer several benefits, ranging from minimized wear to reduced maintenance. Let’s look deeper into caged balls, their benefits, and design t犀利士 ips for success. Caged balls are widely dep......

For instrument bearings, certain special considerations should be emphasized: Heavy press fits should be avoided. Accuracy of mounting surfaces should be equal to accuracy of mating bearing surface. M......

Scoring and wiping are two common causes of oil-film bearing failure. Scoring is characterized by circular parallel grooves on the bearing lining surface and are heavier at the load zone. Wiping resul......

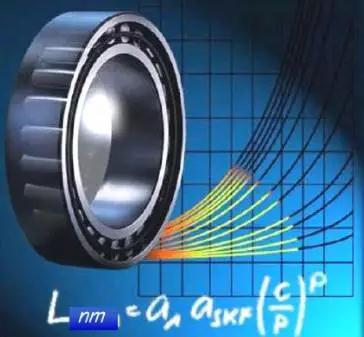

How long will a bearing last? Standardized life equations help to answer. Relative effects of contamination and lubrication condition on bearing life with different load levels. Experience shows seemi......

Approximately 27,000 ceramic tiles cover the exterior of the NASA Space Shuttle—a reusable spacecraft that carries astronauts in a low orbit around Earth. Acting as a thermal barrier to the 1,650°C ge......

Thrust bearing are a type of rotary bearing that permits rotation between parts and is designed to support a high axial load while doing so (parallel to the shaft). 犀利士 We specializes in miniature th......

Small to midsize OEMs that now source rotating-equipment products and services through multiple vendors may want to consider using a dedicated, local distributor. Distributors have access to a broad p......

Get out the surgical gloves when working around the most fragile of bearings. Dynaroll miniature ball bearings make a dime look large. (Left)Grooves make room for adhesive to flow without raising runo......

Limiting speed values for instrument bearings are almost impossible to determine. However, generalizations may be made. Bearing size: Highest speeds may be obtained with the smallest bearing. How......

Heat is generated either by shearing of the oil film or by rubbing contact. In hydrostatic and hydrodynamic bearings, heat generation at running speeds is the result of oil shear, and the amount of te......

Bearing torque is the moment required to overcome internal friction to start or maintain rotation of one ring while the other is stationary. Torque or friction generally increases when: Bearing size i......

In some applications, allowable load seriously influences selection. Major variables affecting load capacity are ball size and number and internal geometry of the bearing. Static:犀利士 Primary co......

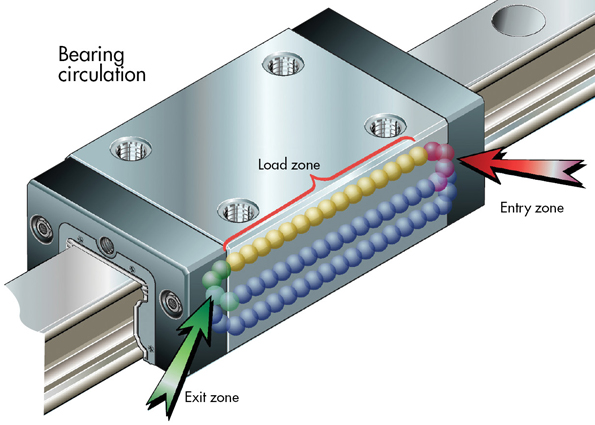

Even with the most-sophisticated motion controller, designers can still find it difficult to attain precise linear motion unless the mechanical components are appropriately designed for the applicatio......

Damaged bearings lead to downtime and lost productivity. Find out how to prevent the damage before it’s too late. The top bearing “killers,” or causes of damage and premature end of bearing life, are ......

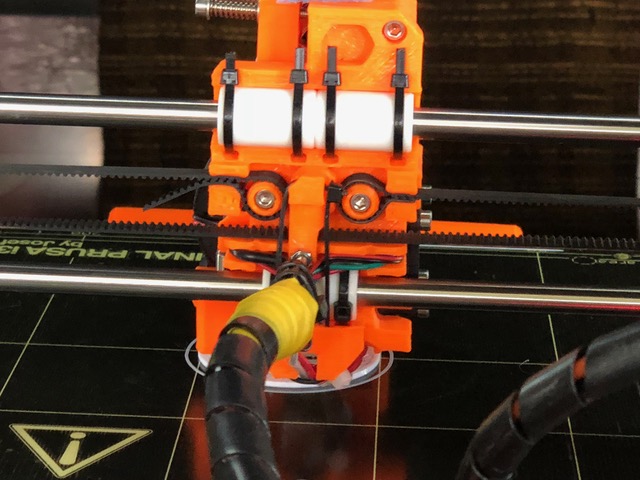

The goal is smooth, jerk-free motion, long-life, durability, and low cost to improve the quality or parts made by 3D printers. Are bearings or bushings best for 3D printers? And how can they be improv......

Whether you use cam follower bearings for cam followers, or for track, guide, or support rollers, their performance depends largely on the type you select. Important factors include loads, speeds, mis......

Linear guides are precision mechanical 壯陽藥 assemblies that operate as part of a system. As such, they can only perform to the degree that they are properly integrated into the overall machine. Merely......

The rolling elements in antifriction bearings are critical components that can affect the overall performance of an entire machine. Engineers must consider their many attributes to get the best bearin......

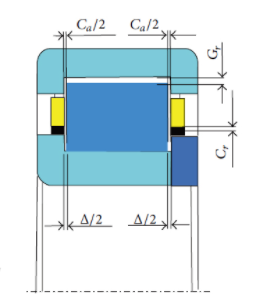

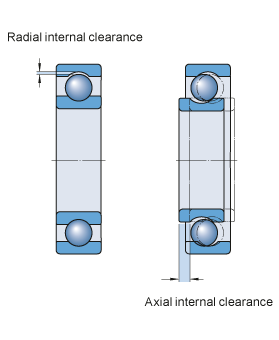

Internal Clearance Internal Radial Clearance of ball and roller bearings is an important parameter in obtaining proper machine operation, optimal bearing life, and a reasonable operating temperature.......

When someone tell you that your bearings are expansive Tell them it is not expansive but WORTHY. When someone 壯陽藥 says your bearings are expansive, answer them like this: Porsche, Land Rover are exp......

Bearings made by normal steel or carbon steel, or even repaired from defective ones, e.g. GCr15 V.S. GCr9… Unqualified bearings counterfeit big brand products, from bearing marking to outside pa......

Custom linear bearings can help solve unique problems. Understanding what situations demand a custom linear bearing is key. Each application is a little bit different. For every load that can be perfe......

“Bearings are as good as their lubrication”. The lubrication is the most important factor for bearing life. Several actual statistics show that incorrect lubrication causes more than 50% o......

Introduction to Six Sigma In today’s information age, news spreads faster than ever. When an event happens halfway around the world it can become common knowledge within hours or even minutes. Compani......

Introduction to Failure Mode and Effects Analysis (FMEA) There are numerous high-profile examples of product recalls resulting from poorly designed products and/or processes. These failures are debate......

Introduction to Problem Solving In the current world market, consumers and organizations have a vast amount of choices regarding the brand or manufacturer of products, parts and materials available to......

Introduction to Corrective Action Preventive Action (CAPA) When illness strikes and we need medical attention, we put our trust in the medical products and care givers to provide relief. We expect the......

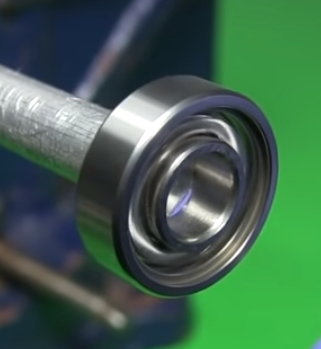

Now we have the correct equipment for the corresponding application and now comes the turn to the installation. An incorrect installation can reduce the useful life of an equipment due to premature fa......

Bearings for Car Gearbox Bearings for Car Air Conditioning Compressor...

Motorcycle壯陽藥 s have become popular all over the world as a convenient means of transportation, and wherever they are found there will always be bearings rotating. Large numbers of bearings are used ......

There’s always a chance that things brea壯陽藥 k. Same with bearings., but it doesn’t mean that we can’t prevent those issues beforehand to avoid further troubles. The below chart will show you how bear......

● What is 8D Problem Solving? When a claim exists and the customer issues you壯陽藥 a corrective action, what should you do? No doubt, you should follow the 8D (Eight Disciplines) problem-sol......

TBB Case of Needle Roller Needle Roller Bearing Used in JAC Gearbox MF70B Heavy Duty Cam Followers – Stud Type Track Rollers Comments from TBB Customer...

Crankshaft, an essencial mechnical part, plays a great role in engine of motorcycle.Motorcycle crankshaft is made of several seperate pieces, today we only focus on the failure analysis of needle roll......

There are many bearings used in various active parts of a motorcycle (such as the direction column, the front and rear wheels, the rear chain plate, the rear gearbox, etc.). Bearings produced by regul......

Riding a bicycle is a common excercise way in our nowaday life. But how much do you know about one of the most important parts in a bicycle–BEARING? Please allow me to show you here. Which......

Case No. 1 TBB optimized products can work under higher load rating with longer lifetime. Case No. 2 Case No. 3 Bearing Durability Test Comparison — Needle Roller Bearing HK1010Application: Auto......

● Significance & Application of CQI-9 HTSA The North American automotive association AIAG (Automotive Industry Action Group) is the publisher of the CQI standards (Continuous Quality Improvement).......

1. TBB Busy Apr壯陽藥 il 2. TBB Handcraft Lesson Look, except bearing, we also had many fun times in office! On the second week, TBB members enjoyed very interesting handcraft lessons at office. The han......

Jaxx Wallet Download vs Competitors In an era of increasing cyber threats, jaxx wallet download provides enterprise-grade security combined with an intuitive interface suitable for both beginners and ......

Jaxx Liberty Wallet Full Review & Features In an era of increasing cyber threats, jaxx liberty wallet provides enterprise-grade security combined with an intuitive interface suitable for both beg......

Download Jaxx Wallet – Best Choice in 2025 Download Jaxx Wallet has emerged as a leading non-custodial cryptocurrency wallet in 2025, trusted by over 5 million users globally for its robust security a......

Vibrating screen bearing is a kind of special bearing designed for vibrating screen equipment, which can maintain stable operation under high-speed vibration, cyclic impact and heavy load conditions, ......

Automotive air conditioning compressor bearings are experiencing the transition from ‘mechanical components’ to ‘intelligent systems’. New energy models of high-pressure, high-temperature, high-freque......

Wheel bearing is one of the key parts of the car, its main role is to carry the weight and provide accurate guidance for the rotation of the wheel hub, which requires it not only to withstand the axia......

Guardian of Motor Performance-Insulated Bearing Motors, as the heart of industry, the stability and durability of their performance is more than ever the key to measuring the performance of the entire......

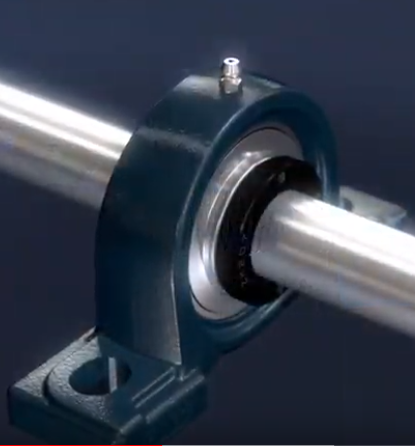

Introduction Have you ever heard about ball-bearing units? Or do you want to know about all the basic knowledge associated with ball-bearing units? No matter what the question is, this article will he......