Introduction Have you ever heard about ball-bearing units? Or do you want to know about all the basic knowledge associated with ball-bearing units? No matter what the question is, this article will help you know everything that you need to know about ball-bearing units. If you belong to a mechanical industry, you must be aware of the uses of ball bearing units in machine parts available in the market. Ball bearing units, instead of quite important components, aren’t very well known among customers. The reason is that either they don’t know what is it or they don’t have any idea of its importance in their machinery. It is interesting to note that ball bearing units are the most essential and effective components in your machine parts. Ball-bearing units have a higher level of versatility as well as cost-effectiveness. These abilities make them perfect for use in industrial applications. You must be wondering to know about their types, applications, common failures, and key quality points. This article has explained everything perfectly. Want to explore? Continue reading to grab its concept! What Are Ball Bearing Units? There exists an insert bearing mounted in the housing of your ball bearing units. The insert…

Introduction If you belong to the agricultural sector, you must be aware of the importance to use right bearings in agricultural sectors so that the agricultural equipment must be able to withstand, corrosion, vibrations, and hard mechanical influences. Some of the most common bearings used in agricultural sectors are listed below: Deep-Groove Ball Bearings Angular Contact Ball Bearings Tapered Roller Bearings Ball Bearing Units Apart from mechanical influences, your agricultural machinery can also be affected by bad weather conditions. There can be drought, rain, winters, and higher temperature changes. To deal with most of these issues, bearings are recommended in agricultural applications. If you don’t know anything about agricultural bearings. Don’t Worry! Continue reading this blog. Deep-Groove Ball Bearings These bearings are quite similar to traditional bearings. Deep groove ball bearing consists of raceways that can easily fit the dimensions of balls to run in them. In other words, the deep grooves result in stable balls. Moreover, they have got the ability to deal with higher loads. Angular Contact Ball Bearings Angular contact ball bearing possesses outer and inner ring raceways. These raceways got the ability to displace themselves from each other in the bearing axis direction. It is another most…

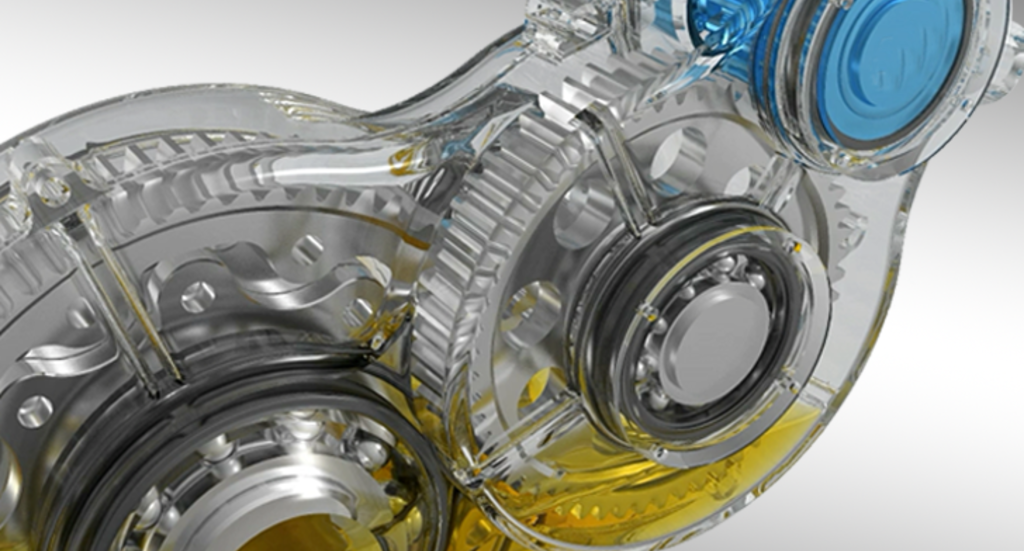

what full-complement cylindrical roller bearings are, common types of full-complement CRBs, those ones popularly used in the gearbox sector, and the reasons and the key quality control points.

“How do we know which lubricant is the most appropriate for the gearbox application?”

Has this question even come to your mind? According to our research, this is the hottest topic our readers pick up for us.