Bearing packaging is an important step in bearing export. Improper packaging will bring many problems to bearing products and customers, resulting in unnecessary losses and trouble. Case example: Many bearing suppliers will encounter the problem of bearing packaging, especially large bearings. We learned about this case of bearing packaging complaint from a produc犀利士 er. Bearing type:24044CA.W33.S1,Product weight:39kg,Packaging method: three layers of wrapping packaging, 10 products stacked in a wooden box. Customer complaint: because the product is too heavy, 10 products are stacked in a wooden box, which can not be taken out and moved with the help of tools. Manual handling is not safe, and it is also easy to cause product damage. Large bearing packaging of TBB Therefore, for large bearings, packaging is very important. TBB was considerate in requiring suppliers to pack these large bearings, which not only solved the risk of bearing damage, but also eliminated customers’ safety concerns and greatly improved customers’ satisfaction. The following are the packaging methods and examples of TBB for large bearings. For bearings heavier than 40kg: they are wrapped in three layers. If multiple quantities are stacked in one wooden box, cross wooden frame shall be used to separate each product….

Difference between high-speed and low-speed bearings Many people may misunderstand it, it’s not that the rotation speed of the bearing itself, but its linear speed. Many low speed bearings can reach tens of thousands of revolutions per minute, on the other hand, for some high-speed bearings, the data of rotations per minute maybe only just a few hundred. There are also some other differences between the two. Generally, low-speed bearings have a rougher appearance, and the joints between parts are looser. To ensure its accuracy, the precision of high-speed bearing is generally very smooth on the surface, and the distance between the inner ring and outer ring is minimal, the accuracy is much higher. Many high-speed bearings are also super-precision bearings. It normally use special high speed grease. In terms of material, there is also a slightly difference between high-speed bearing and low-speed bearing. High speed bearings are generally made of very high hardness steel, which can withstand the pressure caused by excessively high speeds. If it’s low, some common materials are used, the requirements for hardness and durability of the material are relatively reduced. What to do if the high-speed bearing is overloaded and hot? 1) In the case…

When bearings are 100% inspected with all dimensions on approved drawings based on GB or ISO standard, we confirm bearings are qualified. Here we would like to share you with a case: One day we received an urgent request from our customer, that they asked us to deliver one SL bearing (full complement cylindrical roller bearing) to them in short time, reason was that the bearings delivered from their current supplier were rejected by their end user. The problem was the flatness of the end face of outer ring. End user inspected the flatness of the end face of outer ring by ZEISS Coordinate Measuring Machine, result was 0.14mm, thus bearings were rejected due to too big flatness 0.14mm. All other parameters are qualified based on GB/ISO standard. For us such problem is the first time to hear, so what is the flatness of the end face of outer ring? See below sketch: This parameter is generally marked on assembly drawing or not? See below sketch: We go further to analyze this issue, following facts were found: There is no GB/ISO standard of the parameter “flatness of end face of outer ring” for any kinds of bearings, so on assembly…

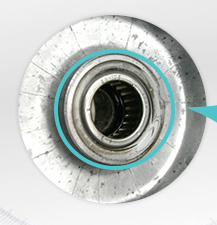

Its construction is simple and cost-effective. The N/O linear guideway assumes the task of being the lateral linear guideway for the table. As the surface guideway is adjusted level with the N/O, the linear guideway systems can be interchanged – depending on whether the grinding spindle is mounted to the right or left.

From the elevator you take at work to the dump truck you see rolling by on the street, hydraulics are everywhere. But hydraulic machines are nothing without their hydraulic pumps.The hydraulic pump is the component of the hydraulic system that takes mechanical energy and converts it into fluid energy in the form of oil flow. This mechanical energy is taken from what is called the prime mover (a turning force) such as the power take-off or directly from the truck engine. The hydraulic pumps market was valued at USD 9.78 billion in 2019 and is expected to reach USD 12.59 billion by 2025, at a CAGR of 4.3% over the forecast period 2020 – 2025. TBB and DANA cooperated to develop the needle roller bearing BH1412, which the bearing surface carburization with special loading. Hydraulic-oil pumps and motors fitted by bearings are developed for the most diverse applications. Needle Roller Bearing No. F45397.2 , F52521.2 , F5083 which are cage every pocket fitted double needles same as INA designation.

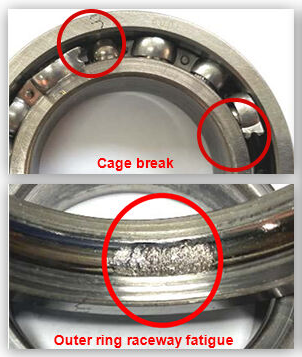

After offering we heard many times voice of “Your price is too high” or “Our current price is 50% lower than yours ” …You have explained to customer that how good quality your product is, showed your testing reports with thousands times, because you know clearly the difference between products of different price level. How do you prove it? Yes, taken inspection for these different products is a good method . TBB did so.However, the testing of basic data such as size, clearance, precision, vibrate. Sometimes there have very big different on measurement, but sometimes there do not have very obvious different on data. What is the deep reason for big price gap? To end the confusion, TBB did further testing- Life Reliability Comparison Test at National Bearing Testing & Inspection Institute.A group of 4 piece of deep groove ball bearings, after rigorous and reasonable experimental process: Firstly, can you guess how the bearings performed ? Here comes some pictures to show how it performance. Secondly, 犀利士 can you guess how many hours the bearings lasting? Here comes the testing results. #1 bearing from TBB OEM product, it lasting for 121.5 hours till the testing ended with good condition.#2 bearing from world well-known…