“How do we know which lubricant is the most appropriate for the gearbox application?”

Has this question even come to your mind? According to our research, this is the hottest topic our readers pick up for us.

To answer this question, often we may simply search the maintenance manual or select a lubricant from a list of lubrication products.

However, we all have the knowledge that this approach does not always give us the best choice, because we must consider many factors beyond that, including lubricant availability, gearbox operating conditions, ease of purchase, and even cost effectiveness.

Choosing the right lubricant is a prerequisite for a well-lubricated gearbox.

Although some gearbox manufacturers have given us general specifications for the parameters related to lubrication selection, this is only a “general specification” and in some cases does not even take into account the different operating temperatures. Therefore, for the technical engineer responsible for selecting the lubricant, it is necessary to know how to make the correct selection.

For all technicians:

1. need to understand and be able to explain well why equipment manufacturers give such general specifications.

2. to be able to adapt these general specifications to the operating conditions when necessary.

So, first we need to understand what determines the choice of lubrication, so that we can follow uniform criteria in selecting the right lubricant to get the best results.

VISCOSITY

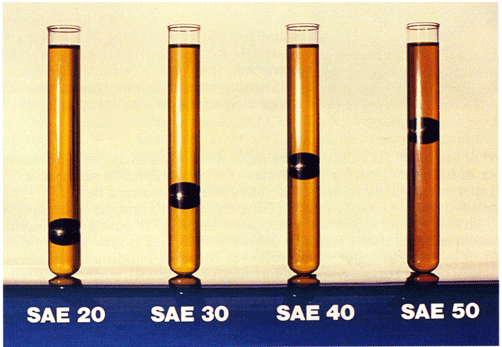

It is often considered the most important characteristic of a lubricant.

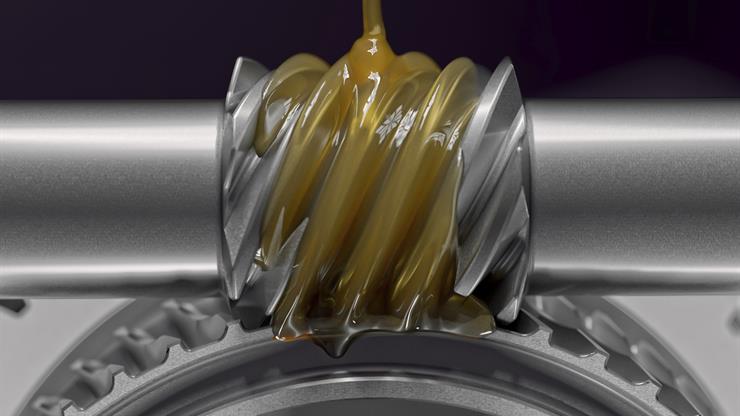

To ensure good lubrication, the lubricant needs to provide a lubricant film of sufficient thickness between the two metal surfaces in contact. This film, which should be thick enough to avoid metal-to-metal contact, but not too thick that would instead introduce more friction from the lubricant itself.

Also, the suitable thickness needs to be considered for a given speed and load.

Choosing the right viscosity level is not a very complicated matter, we can choose a suitable viscosity lubricant mainly by understanding the technical parameters of the lubricated parts. However, before doing so, it is important to understand how viscosity is selected and the factors that influence the requirements.

The viscosity of the lubricant is needed not only to ensure that all mechanisms inside the machinery are properly lubricated, but also that the flow of the lubricant allows it to flush out to each part.

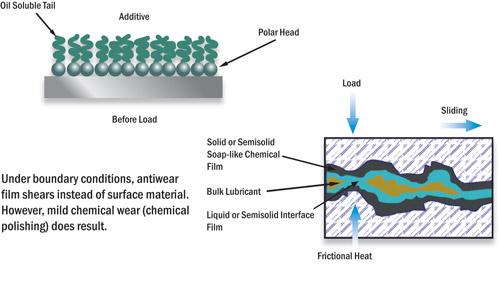

ADDITIVES

The additives used in a lubricant will generally determine the class of lubricant and affect a variety of key performance characteristics under gearbox operating conditions.

Additives are typically dissolved or suspended in the oil in concentrated classes of organic or inorganic compounds. They represent a very small percentage of the lubricant, typically between 0.1% and 30%, and are selected according to the operating conditions of the gearbox.

BASE OIL

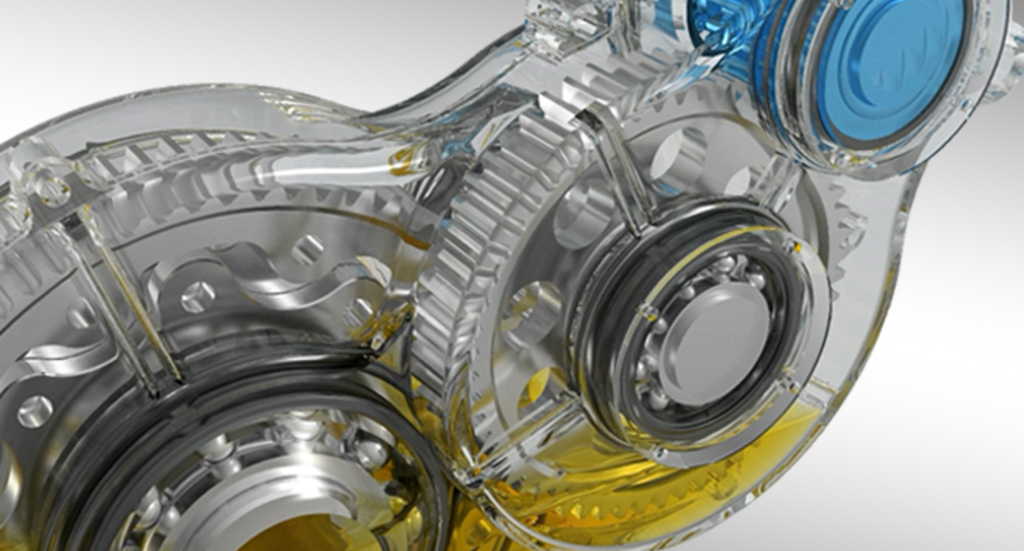

Gear lubricants are generally available in two base oil types, mineral oils and synthetic oils. The final determination of the base oil type is based on factors such as its application conditions and gear type.

High quality mineral base oils perform well in most applications. This is because mineral base oils typically have a higher-pressure viscosity factor than common synthetic oils, thus allowing for greater film thickness at a given operating viscosity.

Synthetic base oils, on the other hand, are more stable to oxidation and thermal degradation, are better suited for applications with high operating temperatures, and allow longer in-lubrication intervals in some applications. In addition, synthetic oils perform better in machines with lower ambient temperatures due to their high viscosity index.

Selecting the right lubrication for a gearbox is similar to most other industrial applications in that there is usually no very fixed standard value to be used as a uniform reference. Therefore, it becomes very important to determine the operating parameters of the gearbox for a given operating condition and the lubrication conditions required for such conditions.

Thanks for your time on TBB Share. If you’re interested in our posts, feel free to discover our technical blog for more interesting themes.

You’re welcome to come to us with any questions on bearing technology or relevant application. We’ll be glad to join in and dissolve all your bearing problems.

No Comments