The manufacturing of metal parts and components is so significant to any economic marketplace, typically, the machine tool industry is utilizing the latest technological advances in manufacturing processes.

Here we’d like to talk about machine tool SPINDLE BEARING

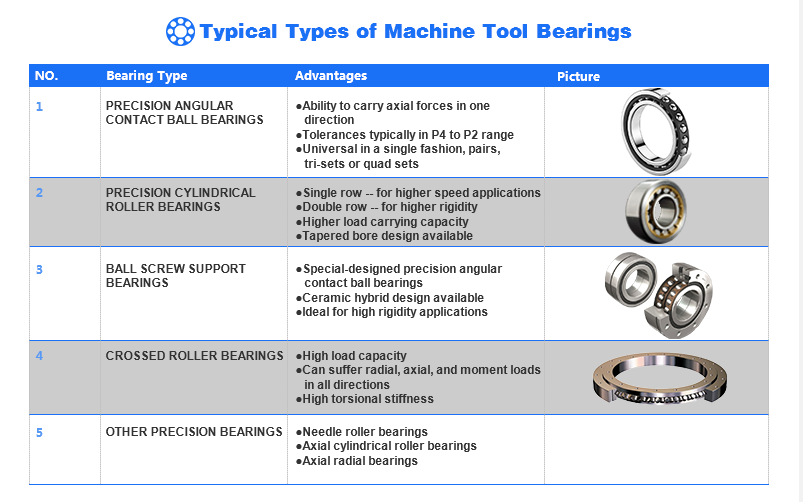

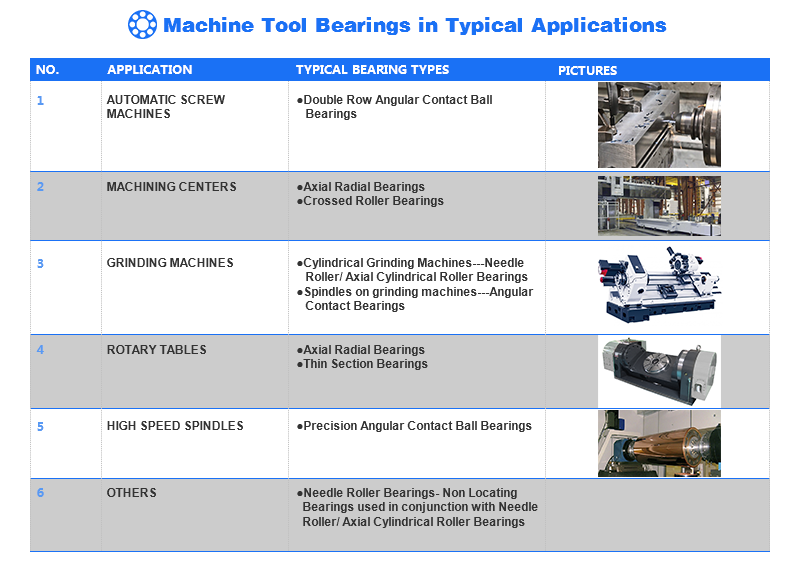

Most spindles use a combination of angular-contact ball bearings and cylindrical roller bearings. The angular-contact types install at a spindle work end because they handle both axial and radial loads. The other end houses a cylindrical roller bearing which, by design, floats or slips axially to compensate for spindle thermal expansion yet operates with zero radial clearance for rigidity.

The basic requirements for spindle:

High running accuracy

High speed

Wide range of speed

High rigidity

Low temperature rise

High reliability

Some of the above requirements are in confrontation, so it’s almost impossible for spindle to meet all the above requirements simultaneously. Therefore, the main performance of spindle should be taken into consideration when designing spindle supporting. Bearing types and matched method depend on machine tool different performances.

3 Comments

Can you quote TYN silent cage? NSK design…

That’s a type of PA-46 cage, our sales department will be in contact with you

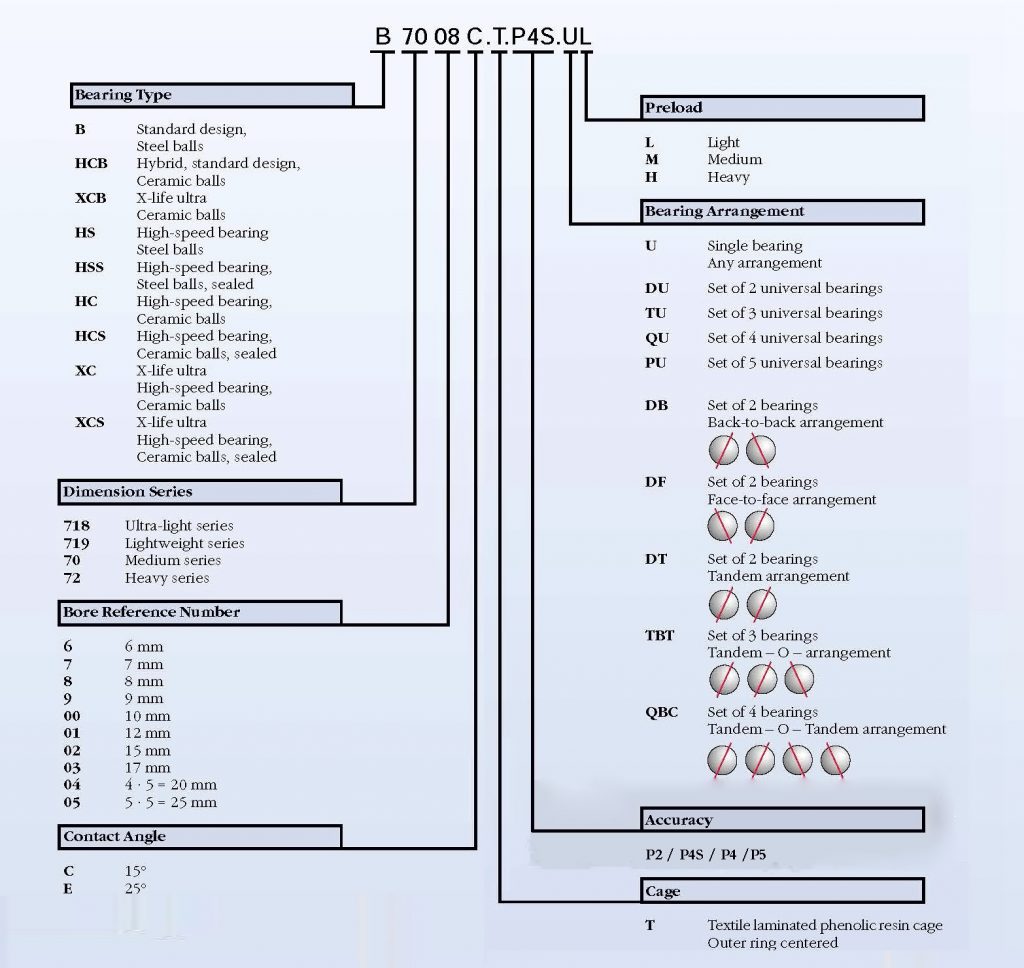

Can you produce this bearing with P2 class?