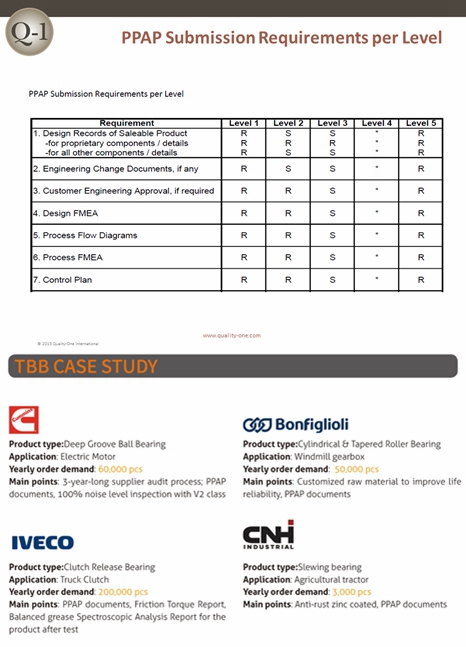

●What is PPAP? PPAP is the abbreviation of Production Part Approval Process, a valuable tool for establishing confidence in component suppliers and their production processes. Initially, PPAP was utilized by the automotive and aerospace industries. PPAP is now being utilized by several industries to improve communication and provide quality products. Within the automotive industry, the ultimate resource for PPAP information is the manual published by the Automotive Industry Action Group (AIAG). PPAP defines the approval process for new or revised parts, or parts produced from new or significantly revised production methods.?It verifies that the supplier understands all customer engineering design specifications and requirements and that the process is capable of consistently producing product meeting those requirements during an actual production run at the quoted production rate. ●How to perform PPAP? The PPAP process consists of 18 elements that may be required for approval of production level parts. Not all of the elements are required for every submission. There are five generally accepted PPAP submission levels. A, 18 elements of PPAP: 1. Design RecordsA copy of the drawing. If the customer is responsible for designing, this is a copy of customer drawing that is sent together with the Purchase Order (PO)….