Slewing bearings usually have a diameter ranging from 0.2 to 10 meters. They consist of mounting holes, internal or external ring gears, lubricating oil holes, and sealing devices. The mounting holes are divided into through holes and threaded holes. Different for different industries The slewing bearing has a variety of structural types to meet its requirements, and can meet the needs of the main engine function with different manufacturing accuracy levels. Therefore, the slewing bearing is an indispensable machine on the slewing device of medium and large construction machinery slewing bearing. component. It plays an important role in the machinery industry, construction industry, coal industry and shipbuilding industry.

The slewing bearing has toothless type, external tooth type and internal tooth type. The structure types slewing bearing generally include single-volley, double-volley, cross-roller, three-row roller, ball-column combined and other forms, of which single-row ball The slewing bearing has a relatively low cost and excellent overall performance. The double volleyball slewing bearing has certain advantages in service life, strong bearing capacity, small swing resistance, large allowable wear, and strict requirements for the mounting base. Raceway rotation accuracy is low; Crossed roller slewing bearings have high accuracy, long life, and high dynamic load capacity, but have high requirements for the rigidity and accuracy of their mounting bases, and the rollers and raceways are prone to contact The edge effect causes the actual stress at the edge to be much greater than the design stress.

The three-row roller slewing ring generally has a very high static load bearing capacity. The ball-column combined slewing ring bears the axial force by a horizontally placed roller, and the steel ball bears the radial Force, the two bear the tipping moment together. Therefore, this type of slewing bearing can bear not only a large axial force, but also a certain tilting moment and radial force, and the cross-sectional size is small, and the production cost is low.

Now let me introduce you some detailed applications of slewing bearings below.

Slewing Bearing For Crawler Piling Machine

The special chassis of the piling machine should have the characteristics of good stability, easy operation and maintenance, and meet the needs of multiple construction methods and configurations of the pile driver equipment. The slewing bearing is mostly used to link the slewing platform and walking chassis of the crawler pile driver chassis. The application of the slewing bearing on the pile driver is the same as that of the excavator. It is used as a mechanically flexible joint to facilitate their 360-degree rotation.

The piling machine generally selects 01 series internal teeth and external teeth, and 11 series internal teeth and external teeth are more. The latter has a smaller clearance than the former and a large overturn. It also requires higher installation accuracy. But for small and medium-sized piling machine, we recommend 01 single-row four-point contact ball slewing bearing.

Slewing Bearing For Concrete Pump Truck

The concrete pump truck is a rising star, combining the concrete conveying and pouring processes together, saving a crane, ensuring the quality of the concrete, cooperating with the concrete conveying truck, realizing a completely mechanized conveying process and improving the transportation efficiency.

The slewing bearing is mainly connected to the rotary table and the fixed turret on the concrete pump truck to meet the requirements of multi-directional rotation during the construction of the pump truck. Generally, the four-point contact ball type 01 series and the cross roller 11 series slewing bearings are generally used for the selection. According to different load and torque requirements, the specific selection needs professional technical talents to help the selection.

Slewing Bearing For Package Machine

Slewing ring bearings for packaging machine usually have large diameters and thin section. which require strict process control.

For example,the qualified package machine slewing bearing have the following features:

1.Low and constant rotational torque

2Can meet the requirements of high speed operation

3.Light weight

4 Controlled axial and radial run-outs

5.Built-in mounting holes for easy installation

The slewing ring can be used in many machines on package line.

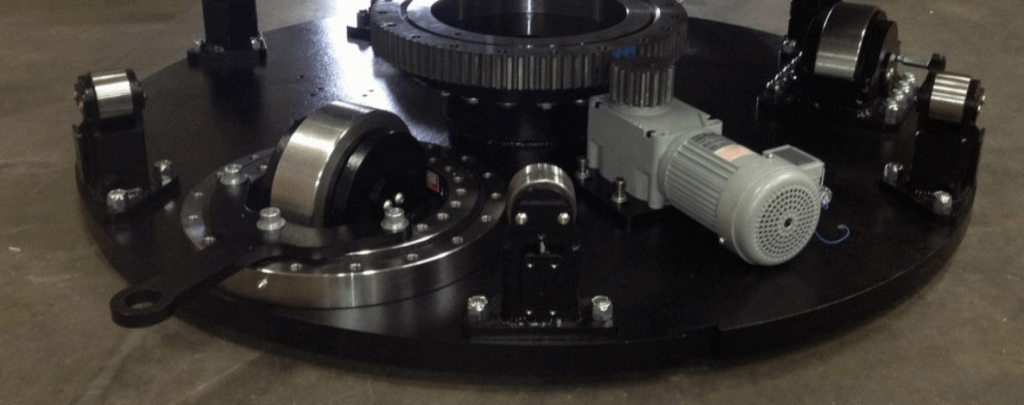

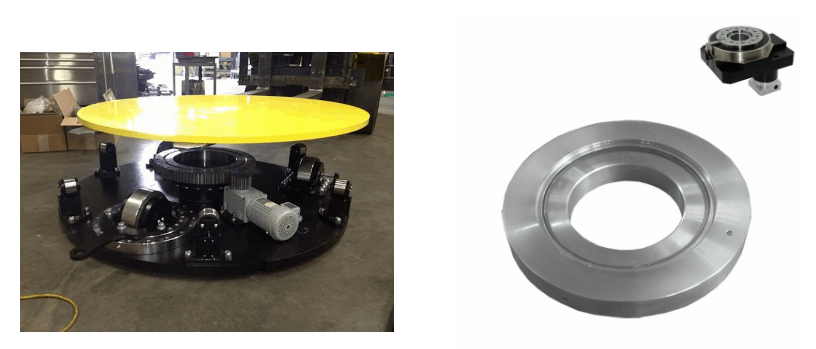

Slewing Ring For Car Turntables

Automobile rotary table is a complete set of electromechanical equipment for rotary platform developed by turntable company in the 1990s according to the needs of domestic and foreign markets. It was initially used in domestic and international auto exhibitions to make rotating displays for cars. Then it is widely used in various industries, including automobiles, exhibitions, metallurgy, mining, machinery, advertising, stage design, manufacturing, etc. The main advantages of the car rotary turntable compared with other transmission rotary tables are high transmission precision, smooth operation and no noise, simple use and easy installation, and can design and produce rotary tables of different sizes and different bearing capacities according to user needs.

Rotating exhibition stands are mainly used in rotating exhibition stands, car exhibition stands, rotating billboards, rotating spheres. Users can choose to use the method according to their needs.

Slewing bearings are often used on car turntables, with flexible rotation and large load. The rotation speed can reach 20 revolutions per minute, and different sizes and materials can be customized according to customer requirements.

Slewing Bearing For Machine Tool Industry

Slewing bearing In the machine tool industry, the slewing bearing of standard structure adopts high-precision grade while applying preload to eliminate clearance and reduce vibration.

The radial run out and diameter tolerance of the slewing bearing range from one thousandth to one ten thousandth of an inch (2.54 tan), the structure is compact, the cross-sectional size is small, and the diameter range can be as small as 50 mm (this type of slewing bearing steel ball The size is smaller than the steel ball size of the heavy series slewing bearing traditionally used). This prompted designers to begin to reconsider the traditional slewing bearing configuration.

The hanger column bearing used to bear radial, axial and moment loads is installed with two sets of ball or roller slewing bearings spaced along the shaft. This configuration is achieved by placing two sets of slewing bearings on the shaft for a long distance Set to obtain higher moment load capacity. However, for this configuration, due to space constraints and installation complexity, it is difficult to adapt to new applications, and this is the advantage of slewing bearings.

Using one set of slewing bearings instead of two sets of slewing bearings can not only reduce the height of the device, but also simplify the assembly structure. Therefore, the slewing bearings are particularly suitable for new operating devices in industrial automation.

The correct choice of slewing bearing depends on the requirements of load, stiffness, speed, size and rotational flexibility. The user and the slewing bearing manufacturer jointly discuss the design goals and the suitability of the slewing bearing, which helps to optimize the performance of the system under the premise of the lowest cost and the guarantee of trouble-free operation.

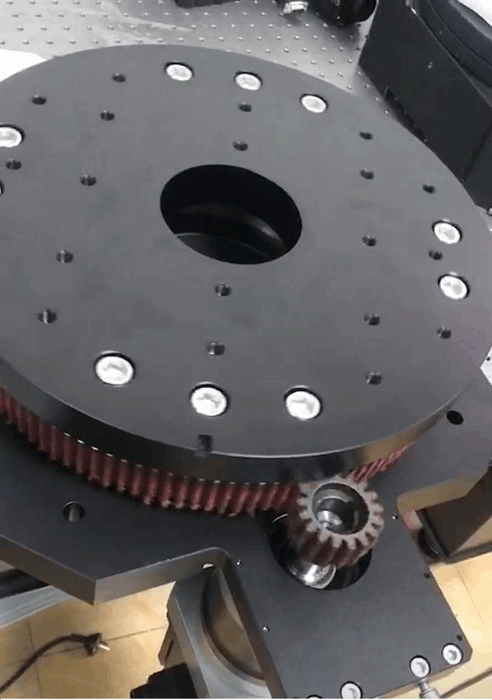

Slewing Ring Bearing With Pinion For Automated Machinery

We can provide customized pinion based on your 2D engineering drawings or 3D models, worn parts or samples with 42crmo or 45 # steel and other materials. We accept customized pinions, mainly the pinion gears for large slewing bearings. Gears are designed to run on parallel shafts to transfer motion and power, and are currently the most commonly used option for supporting slewing bearings.

When transmitting power and uniform rotational motion from one parallel shaft to another, spur gears are the most popular form and the most efficient gear device, and their cost is high. Within the limits of the center distance, the spur gear provides forward constant speed drive, which can be increased or decreased by increasing or decreasing the number of teeth in the driving gear. Run, but they must all have the same modules.

Slewing Bearing For Rotary Table

The rotating table is mainly composed of a base, a rotating part, a slewing bearing, and a mechanical block. The rotating part is composed of upper conveying rollers, lower conveying rollers, and other components. The motor drives the slewing bearing to make a circular motion, and the slewing bearing drives the conveying roller to rotate to realize the change of the conveying direction. Each rotation and stop in place are detected by sensors, and the execution of each instruction is completed by PLC.

With the rapid development of contemporary technology, people’s living standards continue to improve, and home automation equipment has also brought a lot to people. For example, car rotating platform, people can use it to facilitate travel, do not need to reversing and storage, having a rotating platform will help you adjust the parking direction. Being able to achieve this operation, the slewing bearing plays a big role.

Slewing bearings are more and more widely used in the automation industry. According to the self-spirit characteristics of the slewing bearings, they can bear the needs of rotation and can withstand more axial forces and overturning moments. The slewing bearing with teeth can cooperate with the pinion to provide power input, so it is more and more widely used.

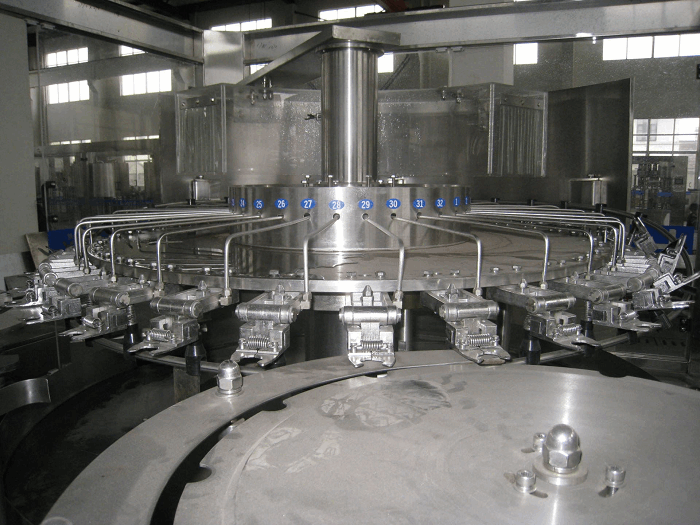

Slewing Ring For The Filling Machine

The light type slewing bearing is light in weight, thin in thickness and flexible in movement. It is widely used in food machinery, filling machinery, environmental protection machinery, etc. Therefore, the light type slewing bearing used by the filling machine has the following specific characteristics:

1. In general, the rolling body of slewing bearing is made of carbon chromium bearing steel with integral hardening. The grade is GCr15 or GCr15SiMn steel; the surface hardening steel is used for the slewing ring ferrule. When the user has no special requirements, 50Mn steel is generally used for manufacturing, but sometimes in order to meet the needs of the host machine in some special applications, other grades of surface hardening steel, such as 42CrMo, can also be selected according to the specific use conditions provided by the user.

2. Cage material

The cage used for the bearing of rotary table has the structural forms of integral type, sectional type and isolation block type. The integral and sectional cages are made of 20 steel or ZL102 cast aluminum alloy. The isolation block is made of Polyamide 1010 resin and ZL102 cast aluminum alloy.

3. Sealing ring material

The sealing ring of slewing bearing is made of oil resistant rubber or NBR.

One Comment

👍