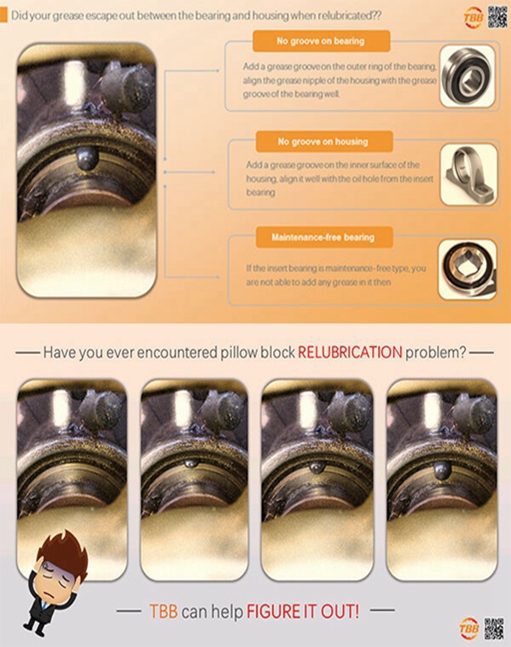

● Functions of a lubricant If rolling bearings are to operate reliably they must be adequately lubricated to prevent metal-to-metal contact between the rolling elements, raceways and cages. Separation of the surfaces in the bearing is the primary function of the lubricant, which must also inhibit wear and protect the bearing surfaces against corrosion. In some applications the lubricant is also used to carry away heat. The choice of a suitable lubricant and method of lubrication for each individual bearing application is therefore important, as is correct maintenance. Lubricants for rolling bearings serve the following functions: * Separate the rolling contact surfaces in the bearing; * Separate the sliding contact surfaces in the bearing; * Protect highly finished bearing surfaces from corrosion; * Provide sealing against contaminants (in the case of grease); * Provide a heat transfer medium (in the case of oil). ● Re-lubrication of pillow block The purpose of any bearing, housed or not, is to reduce the amount of friction between connected or interacting components. The right bearings also reduce the amount of wear-and-tear on the equipment. This, in turn, increases the longevity and operational capabilities of the machinery which requires some form of lubrication. A single…

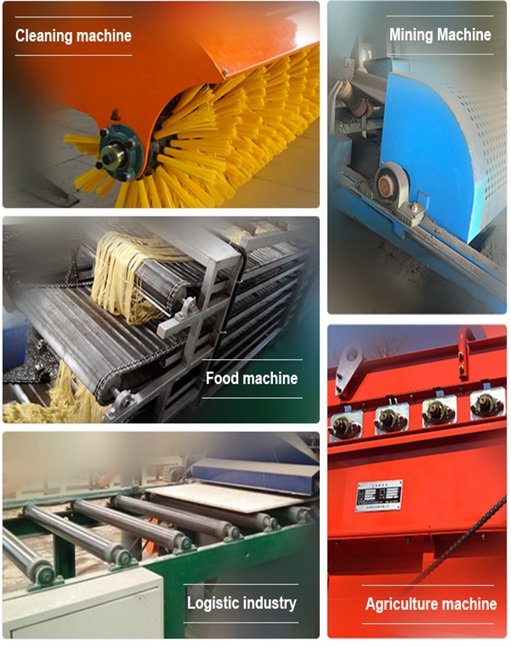

Basic Introduction Pillow block consists of Plummer Block (Bearing Housing) & Insert Bearing(Y-Bearing).It provides supports for a rotating shaft with the help of compatible bearings & other accessories. The units are available in a variety of pillow block, flange, cartridge and take-up mounted configurations with one piece cast iron, ductile iron, stainless steel, thermoplastic or two pressed steel housings. There are many different combinations of insert bearings and housings. Material of bearing units A, Material of bearings: The materials of the race and ball of bearing require enough hardness and the following qualities:(1). Large fatigue strength against repeated stress due to fatigue fracture of the race surface which governs the life of the bearings.(2). High limit of elasticity and high yield strength to prevent deformation when a large load is applied per unit area.(3). Large abrasion resistance against sliding friction between the retainer and the ball.(4). High strength against crack due to impact load and failure caused by improper fitting etc.(5).Small secular change in dimension and shape due to change of structure or internal stress. GCr15 Steel (High carbon chromium bearing steel) satisfies the above comparatively well, and its chemical composition is shown in the following table. Chemical composition of…