How much do you know about Air-Condition Compressor? We summarized here with several typical types of air-conditioning compressors and TBB bearing usages. 1, V5 COMPRESSOR Improved air conditioning pe…

Bearing in ABEC-7(P4) or ABEC-1(P0) for my application? ●What does Bearing Precision mean? When dealing with rolling bearings, precision is described by tolerance classes which include dimensiona…

● Functions of a lubricant If rolling bearings are to operate reliably they must be adequately lubricated to prevent metal-to-metal contact between the rolling elements, raceways and cages. Separation…

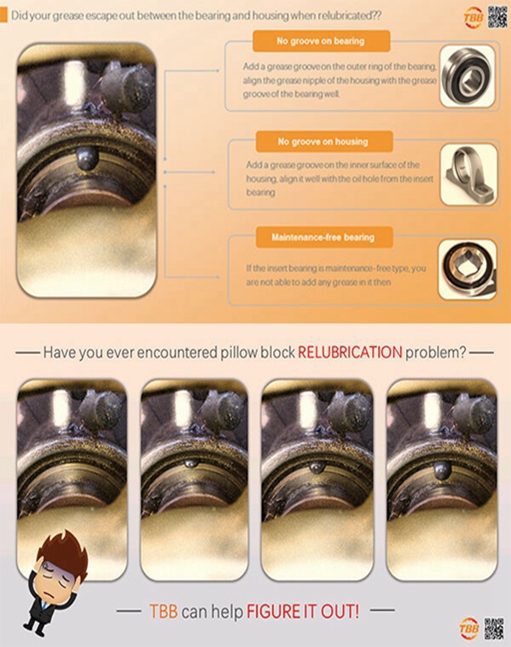

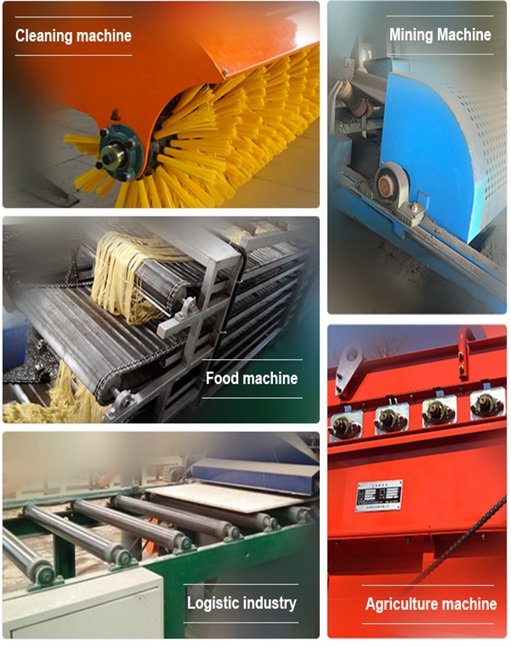

Basic Introduction Pillow block consists of Plummer Block (Bearing Housing) & Insert Bearing(Y-Bearing).It provides supports for a rotating shaft with the help of compatible bearings & other a…

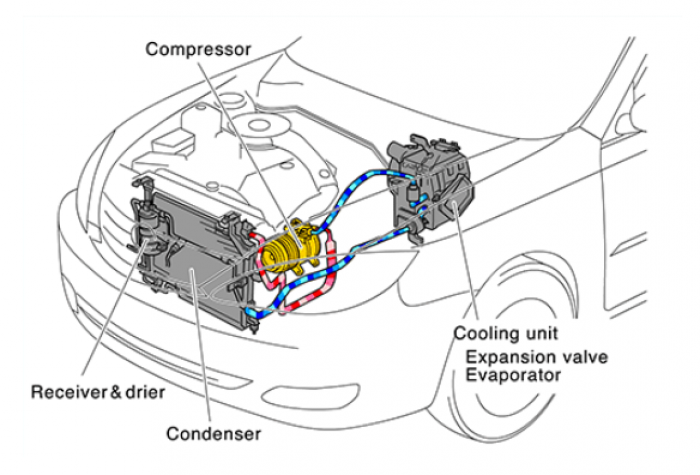

Much like a heart in a human body, the compressor circulates the system’s lifeblood, in this case the refrigerant, that is vital to the proper operation of the air conditioning (A/C) system.The world-…

Rolling element bearings are available in a variety of types, configurations, and sizes. When selecting the correct bearing for your application, it is important to take these factors below into consi…