Bearings for Car Gearbox Bearings for Car Air Conditioning Compressor

Motorcycles have become popular all over the world as a convenient means of transportation, and wherever they are found there will always be bearings rotating. Large numbers of bearings are used in motorcycles. Actual numbers vary depending on the model and other structural factors, but a single motorcycle will have around 20 to 30 bearings built in. These bearings are used in key revolving parts, supporting the vehicle’s running, including: 1. the engine2. the transmission3. the wheels4. the headrace5. the swingarm6. linkage bearing kits7. the steering… They help to reduce friction and to ensure that the motive power of the engine is reliably transmitted to the wheels. The function of motorcycle bearing mainly includes: 1. Facilitating a smooth ride due to low friction and vibration2. Ensuring durability These factors effect fuel consumption and safety, both of which have a close relationship to our lives. We are always pursuing smoothness in bearing rotation and hope that everyone will be able to enjoy smoother rides with reduced power losses. Bearings used in motorcycles require very high rigidity and excellent anti-dust characteristics because they are always exposed to dusty environments where they are subjected to shock loads at high temperatures and high speed rotation. Endurance in the face of water and mud…

There’s always a chance that things break. Same with bearings., but it doesn’t mean that we can’t prevent those issues beforehand to avoid further troubles. The below chart will show you how bearing failure comes and what we can do to prevent it ahead of time to make your application much stronger. With the above knowledge, you don’t have to wait for the symptoms of a bearing failure before you take actions, which can help save your time and money. We TBB Bearing Provision is always here happy to provide you with assistance and support upon your request.

● What is 8D Problem Solving? When a claim exists and the customer issues you a corrective action, what should you do? No doubt, you should follow the 8D (Eight Disciplines) problem-solving methodology system that is designed to find the root cause of a problem, devise a short-term fix and implement a long-term solution to prevent recurring problems. When it’s clear that your product is defective or isn’t satisfying your customers, an 8D is an excellent first step to improving Quality and Reliability. The strength of the 8D process lies in its structure, discipline, and methodology. 8D uses a composite methodology, utilizing best practices from various existing approaches. It is a problem-solving method that drives systemic change, improving an entire process in order to avoid not only the problem at hand but also other issues that may stem from systemic failure. 8D has grown to be one of the most popular problem-solving methodologies used for Manufacturing, Assembly, and Services around the globe. ● Why apply 8D Problem Solving? After notification of a problem, your customer expects you to take the appropriate steps in a timely manner to resolve that problem. The quicker you address the issue, the more satisfied your customer. A thorough 8D…

There are many bearings used in various active parts of a motorcycle (such as the direction column, the front and rear wheels, the rear chain plate, the rear gearbox, etc.). Bearings produced by regular manufacturers are generally tested as qualified products at the factory, but it is also important to install them correctly. During the usage of motorcycle, if the bearing ball cage falls off, the working surface in the rolling groove will be unconventional wearing, peeling off, and the rotation will be stuck. Few of the problems are caused by the bearing quality itself, most part of them are caused during the installation. We will analysis the most common problems one by one as below, hope that we can draw the attention of the manufaturers, the maintenance industry and the owners of motorcycles and avoid unnecessary losses. 1. Bearings on the front and rear hubs and the rear chain plate During the daily usage of the motorcycle, riding in deep water or washing the motorcycle often may make the water running into it, which causes the grease in the bearing invalidated gradually, the rolling groove and the ball in the bearing are seriously worn, and the clearance is obviously increased….

Riding a bicycle is a common excercise way in our nowaday life. But how much do you know about one of the most important parts in a bicycle–BEARING? Please allow me to show you here. Which parts are bearings used in a bicycle? Bearings are used in bicycles mainly to reduce friction. Normally you can find bearings used in the following parts: 1. The front and rear hubs of the wheels 2. The bottom bracket(BB) where an axle connects the two pedal cranks together 3. The pedals 4. The freewheel where bearings help provide one-direction feature 5. The head parts, normally we used angular contact bearing Here we send you part of our most widely used bearing items in bicycle application: TBB Bicycle Bearing Advantages 1. Low noise 2. Low vibration 3. Low friction 4. High precision (ABEC-1/3/5/7 or P0/P6/P5/P4) 5. Great sealing performance 6. Good rotation performance 7. Long-life Analysis of Different Bearing Materials The bearing materials used in bicycle mainly includes: 1. Chrome Steel (GCr15/100C6) 2. Stainless Steel (SS440C/SS420C) 3. Hybrid Ceramic 4. Full…

How much do you know about Air-Condition Compressor? We summarized here with several typical types of air-conditioning compressors and TBB bearing usages. 1, V5 COMPRESSOR Improved air conditioning performance and fuel economy because of its smooth, continuous operation without clutch cycling. Meets vehicle air conditioning demand with its adjustable displacement capability. Compatible with R-12 & R-134a Systems. 2, HS COMPRESSOR HS Compressor which has been Hanon Systems’ first development compressor is fixed swash plate type. It maintains the constant compression ratio and discharge rate of refrigerant. Also, HS Compressor is able to adjust the cooling load through the on/off function of Clutch which is compressor’s component. It’s been one of the Hanon Systems’ competitive products as a low-cost product. 3, R4 COMPRESSOR The R4 compressor has just under 10 cubic inches of displacement per revolution, with four cylinders radiating from its crankshaft. It has basically the same characteristics as the A-6 compressor, except it seems to fit in smaller spaces and is much lighter due to its mostly aluminum construction. The R-4 is larger in capacity than we like in an average classic car installation.

Bearing in ABEC-7(P4) or ABEC-1(P0) for my application? ●What does Bearing Precision mean? When dealing with rolling bearings, precision is described by tolerance classes which include dimensional accuracy and running accuracy.it is regulated by ISO or other related standards. Dimensional Accuracy includes (the items related to the installation of shaft and outer shell): 1. Allowable deviation (acceptable values) for bore diameter, outer diameter, width and assembled bearing width 2. Bore diameter uniformity as seen in chamfer dimensions 3. Allowable inner ring tapered bore deviation and shape error 4. Average bore diameter variation 5. Outer diameter variation 6. Average outer diameter unevenness 7. Raceway width and height variation (for thrust bearings) Running Accuracy includes (items related to the runout of the rotator): Acceptable values for inner and outer ring radial runout and axial runout Acceptable values for inner ring side runout, and outer ring outer diameter runout Permissible variation of raceway thickness of thrust bearing Permissible deviation and variation of tapered hole Permissible variation of inclination of the outer ring surface Here I attached the comparison table from different countries: The applicable accuracy levels are different according to different types of bearings. The following table shows different types of bearings and their…

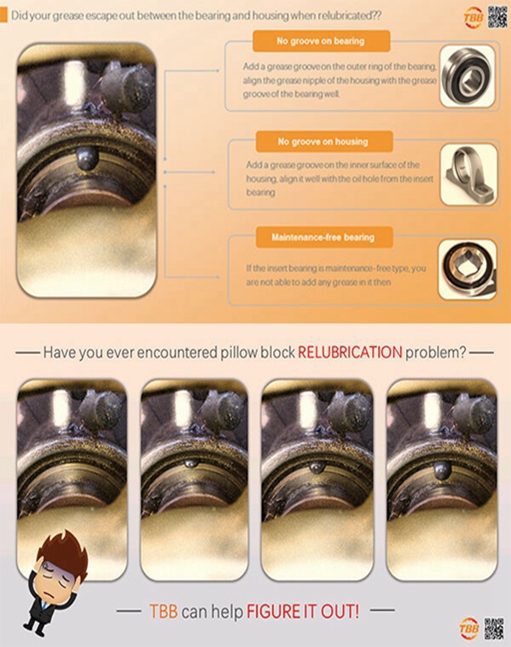

● Functions of a lubricant If rolling bearings are to operate reliably they must be adequately lubricated to prevent metal-to-metal contact between the rolling elements, raceways and cages. Separation of the surfaces in the bearing is the primary function of the lubricant, which must also inhibit wear and protect the bearing surfaces against corrosion. In some applications the lubricant is also used to carry away heat. The choice of a suitable lubricant and method of lubrication for each individual bearing application is therefore important, as is correct maintenance. Lubricants for rolling bearings serve the following functions: * Separate the rolling contact surfaces in the bearing; * Separate the sliding contact surfaces in the bearing; * Protect highly finished bearing surfaces from corrosion; * Provide sealing against contaminants (in the case of grease); * Provide a heat transfer medium (in the case of oil). ● Re-lubrication of pillow block The purpose of any bearing, housed or not, is to reduce the amount of friction between connected or interacting components. The right bearings also reduce the amount of wear-and-tear on the equipment. This, in turn, increases the longevity and operational capabilities of the machinery which requires some form of lubrication. A single…

Basic Introduction Pillow block consists of Plummer Block (Bearing Housing) & Insert Bearing(Y-Bearing).It provides supports for a rotating shaft with the help of compatible bearings & other accessories. The units are available in a variety of pillow block, flange, cartridge and take-up mounted configurations with one piece cast iron, ductile iron, stainless steel, thermoplastic or two pressed steel housings. There are many different combinations of insert bearings and housings. Material of bearing units A, Material of bearings: The materials of the race and ball of bearing require enough hardness and the following qualities:(1). Large fatigue strength against repeated stress due to fatigue fracture of the race surface which governs the life of the bearings.(2). High limit of elasticity and high yield strength to prevent deformation when a large load is applied per unit area.(3). Large abrasion resistance against sliding friction between the retainer and the ball.(4). High strength against crack due to impact load and failure caused by improper fitting etc.(5).Small secular change in dimension and shape due to change of structure or internal stress. GCr15 Steel (High carbon chromium bearing steel) satisfies the above comparatively well, and its chemical composition is shown in the following table. Chemical composition of…