● Functions of a lubricant

If rolling bearings are to operate reliably they must be adequately lubricated to prevent metal-to-metal contact between the rolling elements, raceways and cages. Separation of the surfaces in the bearing is the primary function of the lubricant, which must also inhibit wear and protect the bearing surfaces against corrosion. In some applications the lubricant is also used to carry away heat. The choice of a suitable lubricant and method of lubrication for each individual bearing application is therefore important, as is correct maintenance. Lubricants for rolling bearings serve the following functions:

* Separate the rolling contact surfaces in the bearing;

* Separate the sliding contact surfaces in the bearing;

* Protect highly finished bearing surfaces from corrosion;

* Provide sealing against contaminants (in the case of grease);

* Provide a heat transfer medium (in the case of oil).

● Re-lubrication of pillow block

The purpose of any bearing, housed or not, is to reduce the amount of friction between connected or interacting components. The right bearings also reduce the amount of wear-and-tear on the equipment. This, in turn, increases the longevity and operational capabilities of the machinery which requires some form of lubrication.

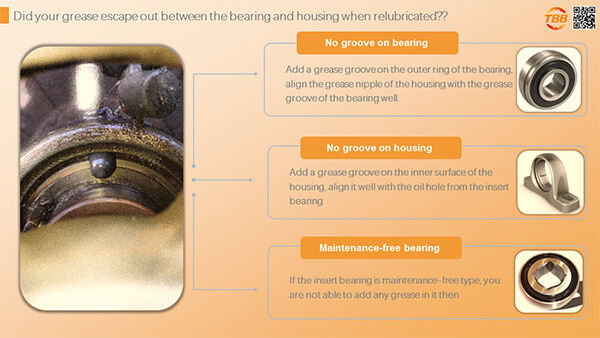

A single oil groove connected with an oil entry hole will distribute the lubricant more positively and more copiously. Sometimes we may encounter this kind of problem that the pillow block is failed with re-lubrication, i.e. grease runs out between the housing and bearing. It is normally because the grease hole of the insert bearing does not match the oil hole in the inner ring of the house.

How to solve this problem then?

1. Add an oil groove in the outer ring of the insert bearing and align it with the oil nipple of the housing properly;

2. Add an oil groove in the inner surface of the housing and correctly match the grease hole of the insert bearing with it

Note: Move

● Re-lubrication of pillow block

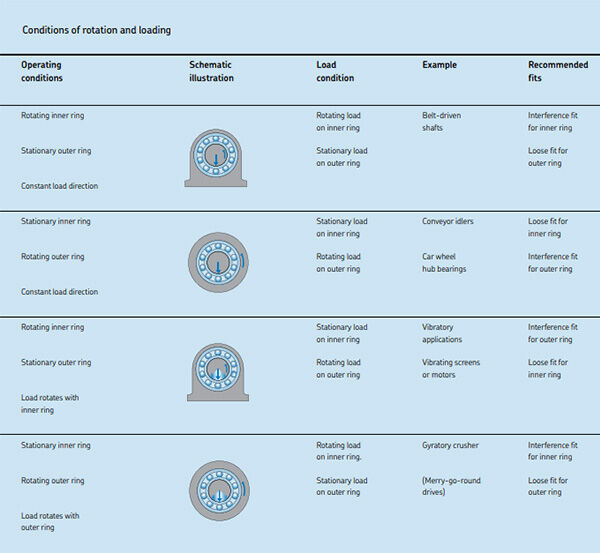

In order for a bearing to function properly and achieve its load carrying ability, the fit between the shaft and the inner ring, and the fit between the outer ring and the housing must suitable for the application. Types of fitting include tight, transition and loose fitting, selection of a proper fit depend upon

1.Shaft and housing material, wall thickness, finished surface accuracy, etc

2.Machinery operating conditions(nature and magnitude of

3. Consideration must also be given to the fact that a solid shaft deforms differently than a hollow one

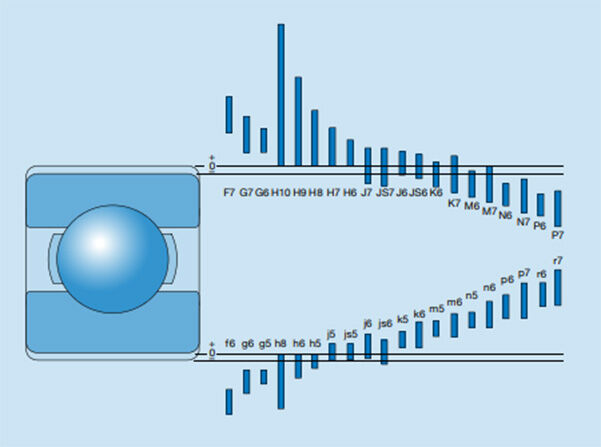

Bearing Fits is divided into two parts: Fitting against Shaft & Fitting against Housing

Fitting against shaft: n8(Loose fit). n9(Loose fit)

Fitting against housing: H7(Loose Fit), J7(Transition fit) & K7(Transition fit)

In

Basic information of pillow block,

Different material of pillow block,

Application of pillow block,

How to mount pillow block,

Lubrication and

Also, if you want to know more about pillow block or TBB Bearing, please feel free to contact us, we are always at the service.

No Comments