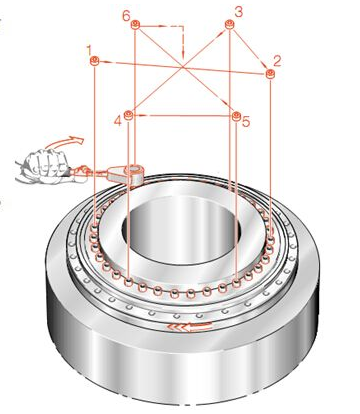

Bearings with diameters between 36 and 169 in. typically cost a lot and have long lead times, forcing end users to keep spare bearings on hand or face extensive downtime should a bearing fail. Therefo…

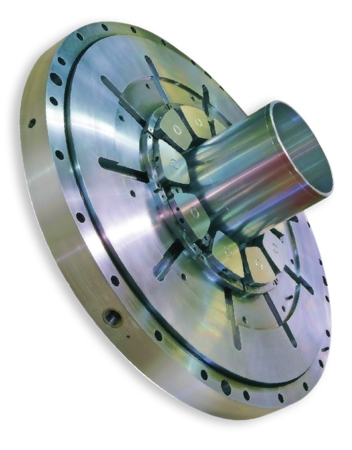

Massive rotors in hydroelectric generators, large ball mills, rolling mills, large electric motors, and steam and gas-turbine generators normally operate with great efficiency on oil films in sleeve a…

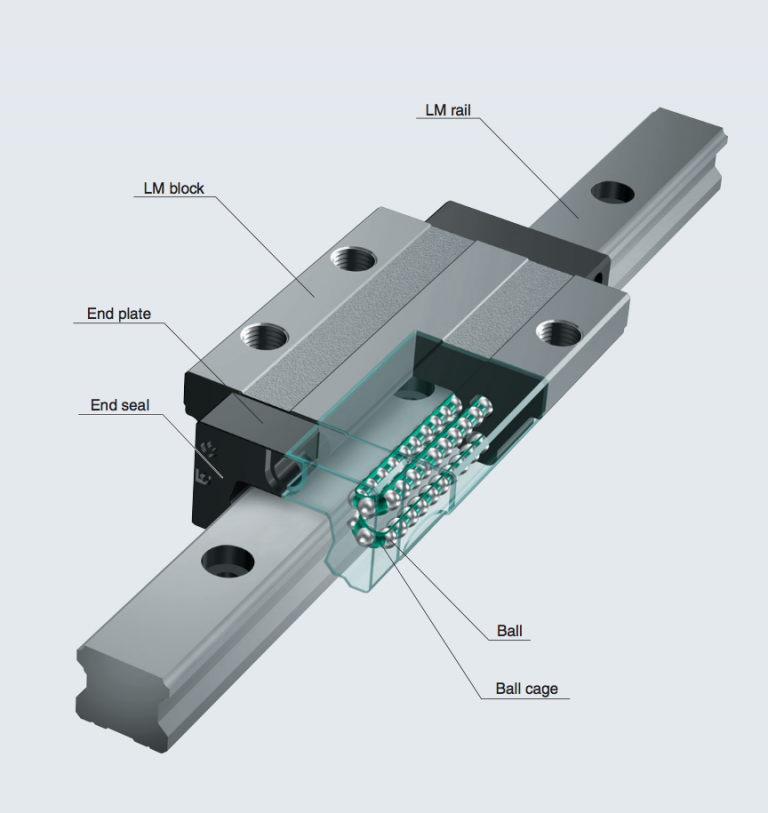

Caged balls offer several benefits, ranging from minimized wear to reduced maintenance. Let’s look deeper into caged balls, their benefits, and design t犀利士 ips for success. Caged balls are widely dep…

For instrument bearings, certain special considerations should be emphasized: Heavy press fits should be avoided. Accuracy of mounting surfaces should be equal to accuracy of mating bearing surface. M…

Scoring and wiping are two common causes of oil-film bearing failure. Scoring is characterized by circular parallel grooves on the bearing lining surface and are heavier at the load zone. Wiping resul…

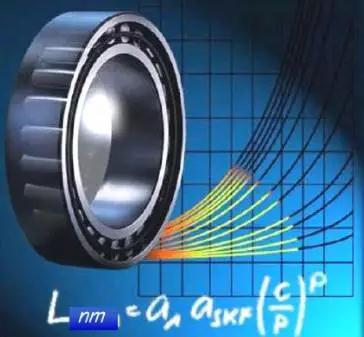

How long will a bearing last? Standardized life equations help to answer. Relative effects of contamination and lubrication condition on bearing life with different load levels. Experience shows seemi…

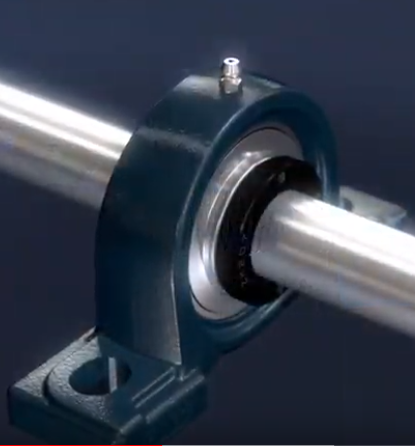

Small to midsize OEMs that now source rotating-equipment products and services through multiple vendors may want to consider using a dedicated, local distributor. Distributors have access to a broad p…

Get out the surgical gloves when working around the most fragile of bearings. Dynaroll miniature ball bearings make a dime look large. (Left)Grooves make room for adhesive to flow without raising runo…

Heat is generated either by shearing of the oil film or by rubbing contact. In hydrostatic and hydrodynamic bearings, heat generation at running speeds is the result of oil shear, and the amount of te…

Bearing torque is the moment required to overcome internal friction to start or maintain rotation of one ring while the other is stationary. Torque or friction generally increases when: Bearing size i…