There’s always a chance that things break. Same with bearings, but it doesn’t mean that we can’t prevent those issues beforehand to avoid further troubles. The below chart will show you how bearing failure comes and what we can do to prevent it ahead of time to make your application much stronger. With the above knowledge, you don’t have to wait for the symptoms of a bearing failure before you take actions, which can help save your time and money. We TBB Bearing Provision is always here happy to provide you with assistance and support upon your request.

How much do you know about Air-Condition Compressor? We summarized here with several typical types of air-conditioning compressors and TBB bearing usages. 1, V5 COMPRESSOR Improved air conditioning performance and fuel economy because of its smooth, continuous operation without clutch cycling. Meets vehicle air conditioning demand with its adjustable displacement capability. Compatible with R-12 & R-134a Systems. 2, HS COMPRESSOR HS Compressor which has been Hanon Systems’ first development compressor is fixed swash plate type. It maintains the constant compression ratio and discharge rate of refrigerant. Also, HS Compressor is able to adjust the cooling load through the on/off function of Clutch which is compressor’s component. It’s been one of the Hanon Systems’ competitive products as a low-cost product. 3, R4 COMPRESSOR The R4 compressor has just under 10 cubic inches of displacement per revolution, with four cylinders radiating from its crankshaft. It has basically the same characteristics as the A-6 compressor, except it seems to fit in smaller spaces and is much lighter due to its mostly aluminum construction. The R-4 is larger in capacity than we like in an average classic car installation.

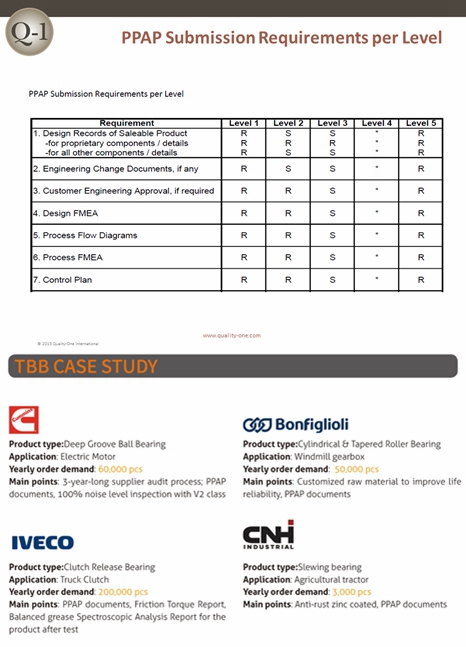

●What is PPAP? PPAP is the abbreviation of Production Part Approval Process, a valuable tool for establishing confidence in component suppliers and their production processes. Initially, PPAP was utilized by the automotive and aerospace industries. PPAP is now being utilized by several industries to improve communication and provide quality products. Within the automotive industry, the ultimate resource for PPAP information is the manual published by the Automotive Industry Action Group (AIAG). PPAP defines the approval process for new or revised parts, or parts produced from new or significantly revised production methods.?It verifies that the supplier understands all customer engineering design specifications and requirements and that the process is capable of consistently producing product meeting those requirements during an actual production run at the quoted production rate. ●How to perform PPAP? The PPAP process consists of 18 elements that may be required for approval of production level parts. Not all of the elements are required for every submission. There are five generally accepted PPAP submission levels. A, 18 elements of PPAP: 1. Design RecordsA copy of the drawing. If the customer is responsible for designing, this is a copy of customer drawing that is sent together with the Purchase Order (PO)….