Bearings for Car Gearbox Bearings for Car Air Conditioning Compressor

TBB Case of Needle Roller Needle Roller Bearing Used in JAC Gearbox MF70B Heavy Duty Cam Followers – Stud Type Track Rollers Comments from TBB Customer

Case No. 1 TBB optimized products can work under higher load rating with longer lifetime. Case No. 2 Case No. 3 Bearing Durability Test Comparison — Needle Roller Bearing HK1010Application: Auto…

How much do you know about Air-Condition Compressor? We summarized here with several typical types of air-conditioning compressors and TBB bearing usages. 1, V5 COMPRESSOR Improved air conditioning pe…

HVAC: is abbreviation of Heating, Ventilating, Air-Conditioning,mean the unit mounted under the instrument panel with heating, ventilating, and air conditioning functions. Including air intake unit, a…

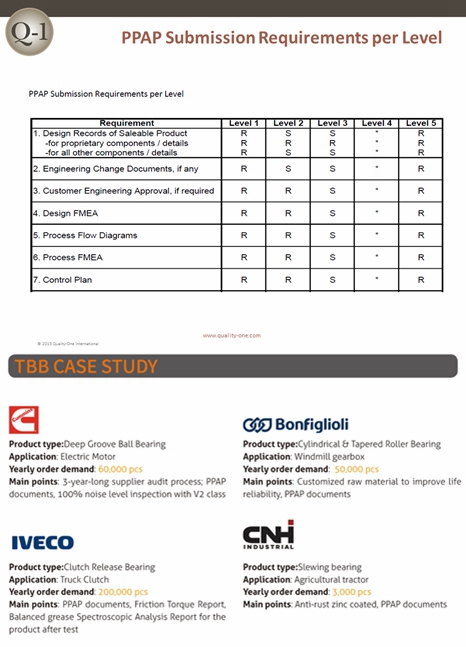

●What is PPAP? PPAP is the abbreviation of Production Part Approval Process, a valuable tool for establishing confidence in component suppliers and their production processes. Initially, PPAP was util…