1) High carbon chromium bearing steel High carbon chromium bearing steel specified in JIS is used as a general material in bearing rings (inner rings, outer rings) and rolling elements (balls, rollers).Their chemical composition classified by steel type is given in “Table 13-1 Chemical composition of high carbon chromium bearing steel”.Among these steel types, SUJ 2 is generally used. SUJ 3, which contains additional Mn and...

Since the characteristics of materials used for cages greatly influence the performance and reliability of rolling bearings, the choice of materials is of great importance. It is necessary to select cage materials in accordance with required shape, ease of lubrication, strength, and abrasion resistance. Typical materials used for metallic cages are shown in Tables 13-3 and 13-4. In addition, phenolic resin machined cages and other synth...

In shipping bearings, since they are covered with proper anti-corrosion oil and are wrapped in antitarnish paper, the quality of the bearings is guaranteed as long as the wrapping paper is not damaged. If bearings are to be stored for a long time, it is advisable that the bearings be stored on shelves set higher than 30cm from the floor, at a humidity less than 65%, and at a temperature around 20℃. Avoid storage in places exposed dire...

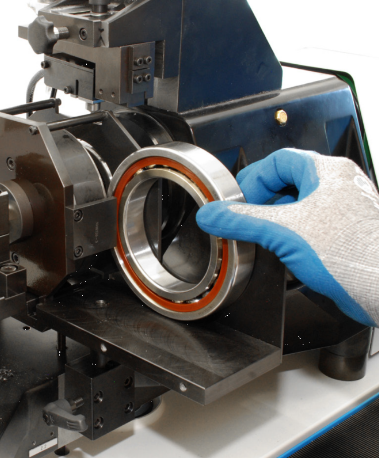

Periodic and thorough maintenance and inspection are indispensable to drawing full performance from bearings and lengthening their useful life. Besides, prevention of accidents and down time by early detection of failures through maintenance and inspection greatly contributes to the enhancement of productivity and profitability. Cleaning Before dismounting a bearing for inspection, record the physical condition of the bearing, including...

It is important for enhancing productivity and profitability, as well as for accident prevention that abnormalities in bearings are detected during operation.Representative detection methods are described in the following section. 1)Noise checking Since the detection of abnormalities in bearings from noises requires ample experience, sufficient training must be given to inspectors. Given this, it is recommended that specific persons b...

In selecting bearings, the most important thing is to fully understand the operating conditions of the bearings. The main factors to be considered are listed below: 1.Installation space Bearing can be installed in target equipment When a shaft is designed, its rigidity and strength are considered essential; therefore, the shaft diameter, i.e., bore diameter, is determined at start.For rolling bearings, since wide variety with different ...

Bearings with diameters between 36 and 169 in. typically cost a lot and have long lead times, forcing end users to keep spare bearings on hand or face extensive downtime should a bearing fail. Therefore, it can make sense to replace a bearing before it degrades. Bearings removed this way often make good candidates for repair or refurbishment. But what qualifies a bearing as repairable? How are repairs carried out? And what kind of resul...

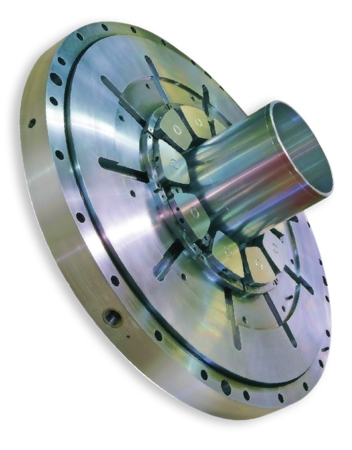

Massive rotors in hydroelectric generators, large ball mills, rolling mills, large electric motors, and steam and gas-turbine generators normally operate with great efficiency on oil films in sleeve and thrust bearings. But trouble arises when rotational speed is too low, as it is at starting and stopping, to generate a complete oil film. Then frictional drag and wear increase with metal-to-metal contact between the bearing and rotating...

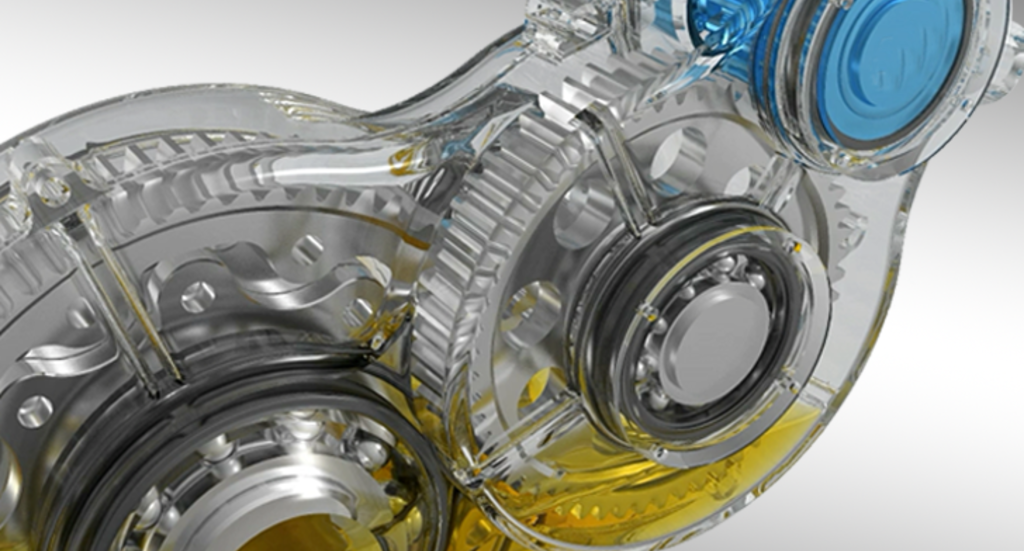

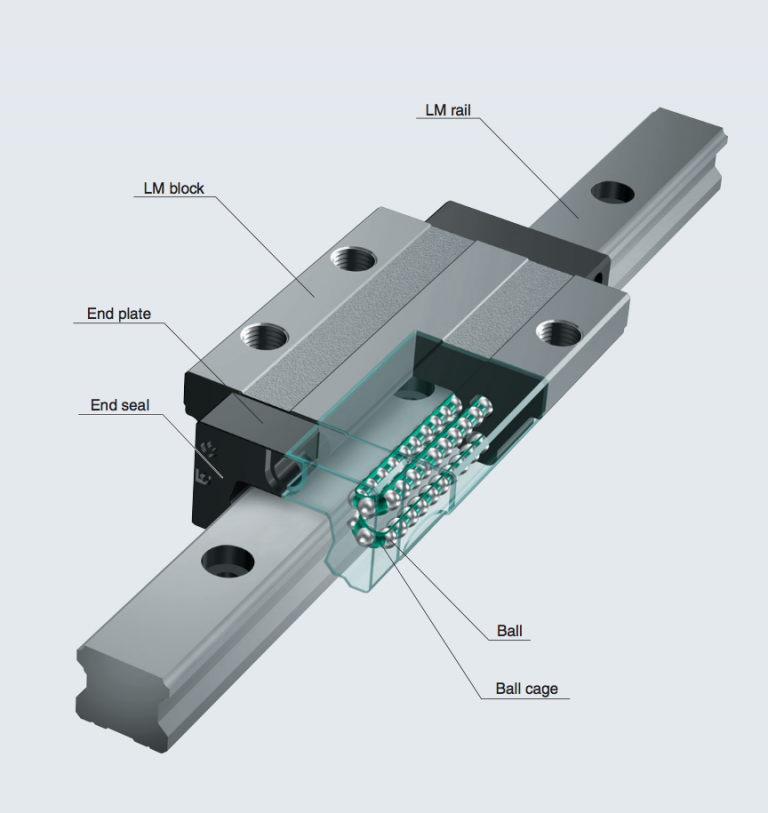

Caged balls offer several benefits, ranging from minimized wear to reduced maintenance. Let’s look deeper into caged balls, their benefits, and design t犀利士 ips for success. Caged balls are widely deployed in motion systems throughout industry. Whether used in ball bearings, linear guides, or ballscrew actuators, caged balls bring both performance and practicality. The addition of the cage minimizes wear, reduces noise, and ex...

For instrument bearings, certain special considerations should be emphasized: Heavy press fits should be avoided. Accuracy of mounting surfaces should be equal to accuracy of mating bearing surface. Misalignment for low torque and running accuracy should not exceed 1/4°. Loading across the bearing during assembly should be avoided. Axial positioning: Accurate axial positioning of the shaft relative to the housing requires shoulder...