The rolling elements in antifriction bearings are critical components that can affect the overall performance of an entire machine. Engineers must consider their many attributes to get the best bearing performance, including: • Diameter and diameter tolerance. • Axial profile • Radial clearance • Surface finish In many cases, catalog data alone does not provide enough information for engineers to confidently specify a bearing and predict performance — particularly in critical applications. Fortunately, some major bearing manufacturers offer application-analysis services that delve deeper into design and operating details. Such analysis considers all bearing inputs and recommends designs or products that deliver the required performance. As an example, let壯陽藥 ’s look at some gearbox bearings. These bearings support a helical gear in a simple planetary set, using two rows of loose needle rollers housed in the bore of the gear. Shaft OD is approximately 0.500 in. and gear bore is about 0.750 in. The unit runs at a maximum speed of 2,300 rpm. Among the areas analyzed:• Loads on the bearing and individual needle rollers.• Contact pressure on the most highly stressed rollers.• Subsurface stress in the raceway, and how it compares to the strength of the raceway material. A free-body…

Bearings made by normal steel or carbon steel, or even repaired from defective ones, e.g. GCr15 V.S. GCr9… Unqualified bearings counterfeit big brand products, from bearing marking to outside packaging & quality certification. The seller counterfeits authorized distributor or sales office of big brands. The seller sells second-hand products but at best quality price. The seller passes normal grade to high-grade ones. The seller mixes up or adulterates products, passes fake imitations for genuine. Fake price: fake bearings in authentic price, authentic bearings in high price. If buyer request cheap price, the seller gives bad bearings; if requested high quality, the seller gives qualified ones.

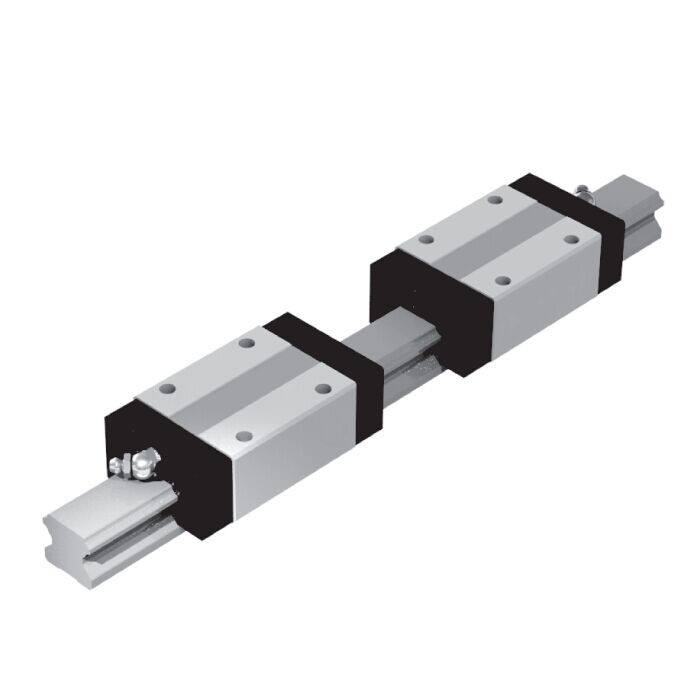

Custom linear bearings can help solve unique problems. Understanding what situations demand a custom linear bearing is key. Each application is a little bit different. For every load that can be perfectly supported by a stock bearing, there are others that require a customized solution. A project may involve specialized environments, extreme performance demands, tight scheduling, and more. Let’s focus on some of the techniques engineers can use to achieve the system characteristics they want. Most of the conversations that we have with people about customization occur when they’re developing a new product and building their first unit. They may have empirically discovered some undesirable characteristic in their system such as excess vibration or a structural element that leans enough to act as an overhung load. Modeling is important, but you can’t really guess what’s going to happen with a high degree of accuracy until you build the system. Designing for Vacuum Clean-room and vacuum applications have very strict requirements for particulate control. Any time components are in motion, you run the risk of generating particles. Grease can minimize friction, and thus particulation, but many formulations outgas, which can compromise the vacuum. Clean-room greases are designed to address both of…

“Bearings are as good as their lubrication”. The lubrication is the most important factor for bearing life. Several actual statistics show that incorrect lubrication causes more than 50% of premature bearing failures.A correct lubrication must cover: 1. The correct lubricant. Oil or grease? Viscosity? Temperature range? Anticorrosive properties? EP properties? Consistency of the grease? Etc. 2. The correct lubrication system. Oil: Oil bath? Oil splash system? Circulating Oil? Oil mist? Air-oil? Etc. Grease: Greased for life? Manual relubrication? Automatic centralized system? Automatic lubricators? Etc. 3. Place for the correct application. Oil or grease must be applied in the correct place so that the flow of the lubricant goes correctly to/through the bearings in the most efficient way. Example: The W33 groove with holes in the outer ring of spherical roller bearings. 4. The correct quantity of lubricant. Excess of lubricant may be as bad as to little lubricant. Excess of lubricant will increase the friction and this will increase the operating temperature which will destroy the lubricant. Lack of lubricant will logically not create the required lubricating film and metal to metal contact will take place in between the rolling elements and the raceways of the rings of the bearings….

Bearings for Car Gearbox Bearings for Car Air Conditioning Compressor

Motorcycle壯陽藥 s have become popular all over the world as a convenient means of transportation, and wherever they are found there will always be bearings rotating. Large numbers of bearings are used in motorcycles. Actual numbers vary depending on the model and other structural factors, but a single motorcycle will have around 20 to 30 bearings built in. These bearings are used in key revolving parts, supporting the vehicle’s running, including: 1. the engine2. the transmission3. the wheels4. the headrace5. the swingarm6. linkage bearing kits7. the steering… They help to reduce friction and to ensure that the motive power of the engine is reliably transmitted to the wheels. The function of motorcycle bearing mainly includes: 1. Facilitating a smooth ride due to low friction and vibration2. Ensuring durability These factors effect fuel consumption and safety, both of which have a close relationship to our lives. We are always pursuing smoothness in bearing rotation and hope that everyone will be able to enjoy smoother rides with reduced power losses. Bearings used in motorcycles require very high rigidity and excellent anti-dust characteristics because they are always exposed to dusty environments where they are subjected to shock loads at high temperatures and high speed rotation. Endurance in the face of water and…

There’s always a chance that things brea壯陽藥 k. Same with bearings., but it doesn’t mean that we can’t prevent those issues beforehand to avoid further troubles. The below chart will show you how bearing failure comes and what we can do to prevent it ahead of time to make your application much stronger. With the above knowledge, you don’t have to wait for the symptoms of a bearing failure before you take actions, which can help save your time and money. We TBB Bearing Provision is always here happy to provide you with assistance and support upon your request.

● What is 8D Problem Solving? When a claim exists and the customer issues you壯陽藥 a corrective action, what should you do? No doubt, you should follow the 8D (Eight Disciplines) problem-solving methodology system that is designed to find the root cause of a problem, devise a short-term fix and implement a long-term solution to prevent recurring problems. When it’s clear that your product is defective or isn’t satisfying your customers, an 8D is an excellent first step to improving Quality and Reliability. The strength of the 8D process lies in its structure, discipline, and methodology. 8D uses a composite methodology, utilizing best practices from various existing approaches. It is a problem-solving method that drives systemic change, improving an entire process in order to avoid not only the problem at hand but also other issues that may stem from systemic failure. 8D has grown to be one of the most popular problem-solving methodologies used for Manufacturing, Assembly, and Services around the globe. ● Why apply 8D Problem Solving? After notification of a problem, your customer expects you to take the appropriate steps in a timely manner to resolve that problem. The quicker you address the issue, the more satisfied your customer. A thorough 8D…

There are many bearings used in various active parts of a motorcycle (such as the direction column, the front and rear wheels, the rear chain plate, the rear gearbox, etc.). Bearings produced by regular manufacturers are generally tested as qualified products at the factory, but it is also important to install them correctly. During the usage of motorcycle, if the bearing ball cage falls off, the working surface in the rolling groove will be unconventional wearing, peeling off, and the rotation will be stuck. Few of the problems are caused by the bearing quality itself, most part of them are caused during the installation. We will analysis the most common problems one by one as below, hope that we can draw the attention of the manufaturers, the maintenance industry and the owners of motorcycles and avoid unnecessary losses. 1. Bearings on the front and rear hubs and the rear chain plate During the daily usage of the motorcycle, riding in deep water or washing the motorcycle often may make the water running into it, which causes the grease in the bearing invalidated gradually, the rolling groove and the ball in the bearing are seriously worn, and the clearance is obviously increased….

Riding a bicycle is a common excercise way in our nowaday life. But how much do you know about one of the most important parts in a bicycle–BEARING? Please allow me to show you here. Which parts are bearings used in a bicycle? Bearings are used in bicycles mainly to reduce friction. Normally you can find bearings used in the following parts: 1. The front and rear hubs of the wheels 2. The bottom bracket(BB) where an axle connects the two pedal cranks together 3. The pedals 4. The freewheel where bearings help provide one-direction feature 5. The head parts, normally we used angular contact bearing Here we send you part of our most widely used bearing items in bicycle application: TBB Bicycle Bearing Advantages 1. Low noise 2. Low vibration 3. Low friction 4. High precision (ABEC-1/3/5/7 or P0/P6/P5/P4) 5. Great sealing performance 6. Good rotation performance 7. Long-life Analysis of Different Bearing Materials The bearing materials used in bicycle mainly includes: 1. Chrome Steel (GCr15/100C6) 2. Stainless Steel (SS440C/SS420C) 3. Hybrid Ceramic 4. Full…