With the wide application of PWM and IGBT in motor, the problems caused by electromagnetic damage such as electric corrosion of bearing are more and more prominent.

What causes electromagnetic damage of bearing?

Common mode voltage is the main cause electromagnetic damage.

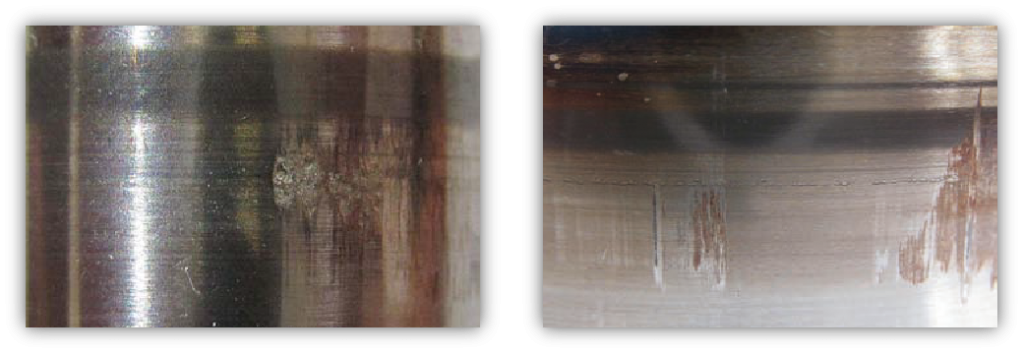

When the b犀利士 earing is running at high speed, there will be a fluid oil with strong insulation between the roller and the inner & outer raceways. Due to the constant change of common mode voltage, fluid film is charging and discharging, leading to currents. It has a continuous thermal effect on the lubricant, which will cause deterioration, deficiency, carbonization of lubricant, thus affecting the life of bearing. Under the deficiency of lubricant, the shaft current directly passes through the bearing and discharges on the contact surface of the bearing, which will cause teeth electric erosion along the rolling direction.

When the common mode voltage on both sides of the fluid film is too large, the fluid film will be broken down, resulting in EMD currents. It will cause electrical erosion pits on the raceway, which usually need to be observed under the microscope. And the raceway appears dim and tarnished.

Solution

In PWM Frequency Modulation Motor, EMD current is the main factor of electric corrosion. Using insulation bearing can effectively reduce the value of EMB current to protect the bearing.

For insulation bearing, insulation resistance and AC withstand voltage are the most important performance indexes. And it is also necessary to control the coating thickness and the coating capacitance within the appropriate range.

4 Comments

Insulated bearing is not so widely used in the market, and price is too high also.

Yeah, but every coin has its worth, for some particular application, you need it

Dear, can you supply INSOCOAT bearing SKF?

Insocoat Bearing is one of our most popular products, we will contact you through email