Slewing Bearing, also known as slewing ring bearing, turntable bearing, slewing ring, etc, is widely used in modern industries.

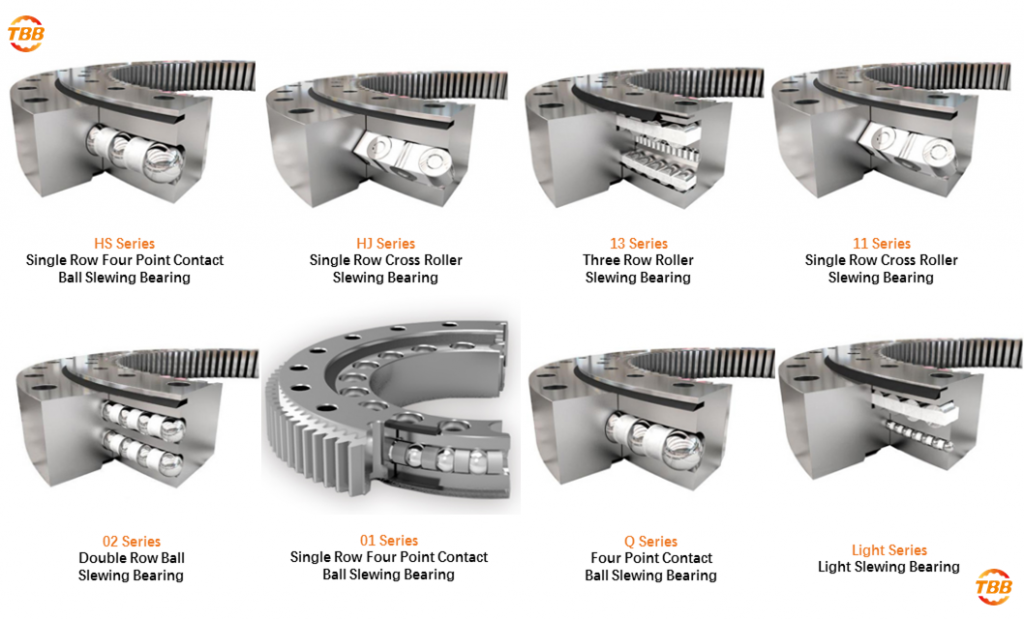

Types of Slewing Bearing

Single-row ball type (01 series, HS series, Q series)

Double-row ball type (02 series)

Three-row roller type (13 series)

Single-row cross roller type (11 series)

Double-row ball type (07 series) )

Light and non-standard specifications series slewing bearing

Manufacturing Processing

- Raw material inspection

- Chemical composition analysis

- Heat treatment

- Raceway hardness inspection

- Gearing processing

- Gear inspection

- CNC drilling processing

- Mounting hole inspection

- Turning processing

- Raceway inspection

- Assembly

- Finished product inspection

- Qualified stock

In the entire cycle of slewing bearings from forgings to finished products to the hands of customers, the tooth processing technology takes the longest time, and the length of the delivery period depends greatly on the timeliness of the slewing gear processing. Hobbing machining accounts for about 45% of the entire slewing bearing processing volume, or even a larger proportion. For large diameter and large modulus slewing bearing machining, milling gear machining also reflects the characteristics of good machining accuracy, high efficiency, and convenient programming.

In recent years, in order to adapt to the improvement of machining precision and production efficiency requirements of slewing bearing processing, the hobbing technology has continuously developed in the direction of full numerical control, zero transmission, high speed, high precision, and intelligence. After the epidemic, the infrastructure construction, new energy equipment and other fields have been vigorously supported by the sta壯陽藥 te. The market demand for slewing bearings has also increased sharply, and there is often a shortage of supply.

Slewing Bearing Cage

The main purpose of the slewing bearing cage is to maintain the proper spacing between the rolling elements and avoid immediate contact between the adjacent rolling elements to maintain the friction and the resulting heat to a low level; make the rolling elements uniform Spreading in all bearings, so that the load can be spread evenly in all bearings, so that the load can be spread more evenly and reduce noise. In the no-load area, the rolling elements are correctly guided to improve the rolling standard in the bearing and avoid destructiveness.

For the separated bearing, when installing or disassembling in one of the bearing rings, the rolling element can be maintained in an integrated cage. It must bear the ground stress caused by friction, strain and inertia moment, and also bear some lubricating fluid. The preservatives in the lubricating fluid or the individual characteristics caused by its embrittlement, the organic chemical etching effect of solvents or coolants, etc. Therefore, the design and raw materials of the cage are particularly important for the reliability of the bearings for their performance.

Therefore, bearing manufacturers have developed and designed cages of various types, designs and raw materials for different types of bearings.

In addition, according to the application characteristics of bearings, the design and manufacture of bearing cages have unique performance requirements such as impact resistance, fatigue relief, high toughness, wear resistance, corrosion resistance, and self-lubrication according to the working conditions of bearing applications. The cage should carry out surface strengthening solutions, surface organic chemical solutions, surface barrel plating, gold plating, electroplating and other processing techniques to improve reasonable application performance.

For the design and calculation of the main parameters of various cages, you can refer to the relevant commodity design methods for design and calculation.

The ROLE of slewing bearing cage:

1. Guide and drive the slewing bearing rolling body to roll on the correct raceway.

2. The cage separates the rolling elements at equal distances and is evenly distributed on the circumference of the rolling track to prevent slewing bearing collision and friction between the rolling elements during work.

3. In the split bearing, the rolling element is combined with a ferrule to prevent the rolling element from falling off.

There are many equally spaced pockets on the slewing bearing cage. The shapes of the pockets are spherical, circular, oval, rectangular, and toothed. The size is larger than the size of the rolling body. The difference between the two is the pocket gap. The connecting part between the frame windows is called the lintel, which plays the role of connecting and increasing the strength of the cage.

Inspection And Repair Problems Before Using Slewing Bearing

1. The idling of newly purchased products is not flexible. Please check the production date of the slewing bearing. If the time is long (such as more than half a year) and the climate is cold, there may be impurities such as salt mist in the raceway, which may cause malfunctions (cold areas, winter is more prominent). Remedy: It can be used normally if it can be operated without any other abnormality after boosting.

2. The operation is not flexible after installation. It may be that the installation surface of the main machine and the slewing bearing installation surface are not well coordinated, so that the axial clearance of the slewing bearing after installation cannot compensate for the deformation of the slewing bearing. The slewing bearing is in a negative clearance state, and the rolling element is difficult to run in the raceway (sometimes accompanied by different Ringing); or poorly meshed large and small gears; or foreign objects stuck in the large and small gears. Remedy: re-machine the installation plane of the host machine to make the installation plane meet the requirements; readjust the backlash of the meshing of the large and small gears according to the requirements, especially pay attention to the maximum position of the gear jump; check to ensure that there is no foreign matter in the meshing position of the large and small gears; replace a rotation with a slightly larger gap Support.

3. The operation of slewing bearing is not flexible during use. The sealing strip is damaged, causing foreign matter to enter the raceway (such as poor operating conditions, immersion of dust in the raceway, etc.); check the meshing of the gears, whether there is foreign matter or broken teeth.

The Role Of Slewing Bearing Grease

The slewing bearing must be lubricated during use, and its lubrication effect is as follows:

1. Reduce sliding original rub. Although the slewing bearing is mainly rolling friction, due to manufacturing deviation and elastic deformation of the part under load, it is often between the rolling body and the raceway, between the rolling body and the cage; the cage is inside and outside There is sliding friction between the rings. This sliding friction increases with the increase of speed and load. In order to reduce friction and wear and prevent burns and corrosion, rolling bearings should have good lubrication.

2. Derive the heat generated when the slewing bearing works.

3. Prevent the rolling body and the polished surface and other surfaces of the channel from being corroded.

4. The shaft is elongated due to the increase in operating temperature, which makes it easy to move the movable bearing in the box or on the shaft in the axial direction.

5. Fill the gap between the bearing parts. When the bearing and moving parts are filled with grease, it can prevent dust, moisture and other sundries from entering the bearing and improve the function of the sealing device

The APPLICATION part will be followed in our next post.

2 Comments

I have question about slewing ball bearing.that, why some slewing bearing have cage and some have spcers? I guess that the purpose is same for both to separate the balls.

then why?

Thank you for reply

Why slewing bearing have “SOFT ZONE‘’ on the rings?