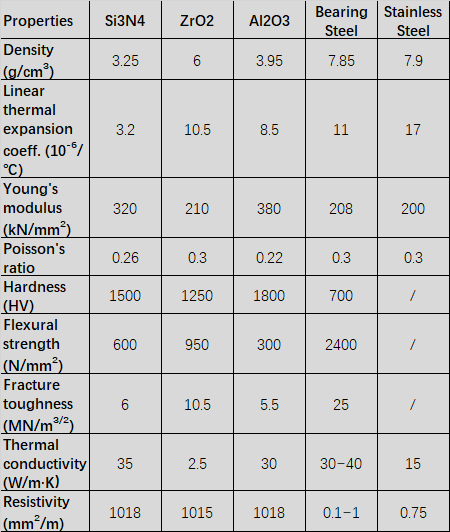

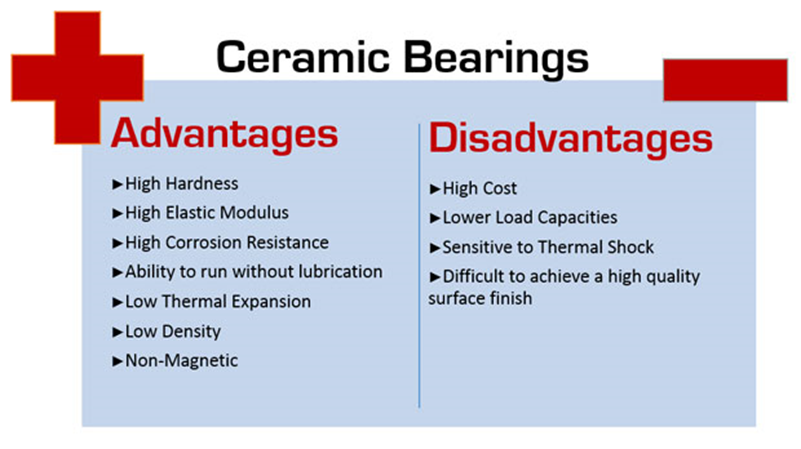

With the development of mechanical manufacturing industry towards high precision and high speed, the application range of bearings is more and more wide, and the performance requirements of bearings are also higher and higher, especially in some special working environment, metal bearings can not adapt to the demand, or even can not work at all. Because of its low density, high modulus of elasticity, low coefficient of linear expansion, wear resistance, high temperature resistance, corrosion resistance and other excellent properties, ceramic material has become an ideal material for high-speed manufacturing of precision bearings.

Advantages and Characteristics of Silicon Nitride Ceramics

Although silicon nitride is not the hardest and the most tough material in industrial ceramics, it is considered to have the best mechanical and physical properties in high performance bearing applications.

Heat Resistance

Generally, when the service temperature of steel bearings exceeds 120 ℃, the hardness will decrease and the rolling life will also decrease. Silicon nitride has good temperature characteristics, especially suitable for high temperature environment.

Centrifugal Force

The density of silicon nitride is about 3.24 × 103kg / m3, while the density of bearing steel is about 7.8 × 103kg / m3, which is only about 40% of the density of bearing steel. Therefore, when the rolling element is used as bearing, the increase of rolling element load caused by centrifugal force can be restrained when the bearing rotates at high speed.

Linear Thermal Expansion Coefficient

The linear thermal expansion coefficient of silicon nitride is about 1 / 4 of that of bearing steel, so the size change with temperature is small, so it is beneficial to use in the environment with large temperature change.

Hardness, Elastic Coefficient and Poisson’s Ratio

Because the elastic coefficient of silicon nitride is about 1.5 times that of bearing steel, the elastic deformation of relative load is small and the rigidity of relative load is high.

Corrosion Resistant, Non-Magnetic and Electrical Insulation

When steel bearings are used in chemical machinery, food, marine and other departments, their corrosion is a problem.犀利士

In the strong magnetic environment, when steel bearings are used, the micro powder from the bearing itself is absorbed between the rolling element and the rolling surface, which will be the main reason for the bearing spalling damage and the increase of noise.

3 Comments

Perfect material, just the costs…

Good article👍

Insulation bearing with material Si3N4 is possible?