Apprehensions about a steel shortage in China are unfounded and the recent price increases have largely been a result of short-term market-related factors, experts said. “There is no shortage of supplies. The price surge is not an exact reflection of the current supply and demand situation,” said Wang Jing, an analyst with the Lange Steel Information Research Center. On Monday, steel product prices, tracked by the center, ro...

With the development of mechanical manufacturing industry towards high precision and high speed, the application range of bearings is more and more wide, and the performance requirements of bearings are also higher and higher, especially in some special working environment, metal bearings can not adapt to the demand, or even can not work at all. Because of its low density, high modulus of elasticity, low coefficient of linear expansion,...

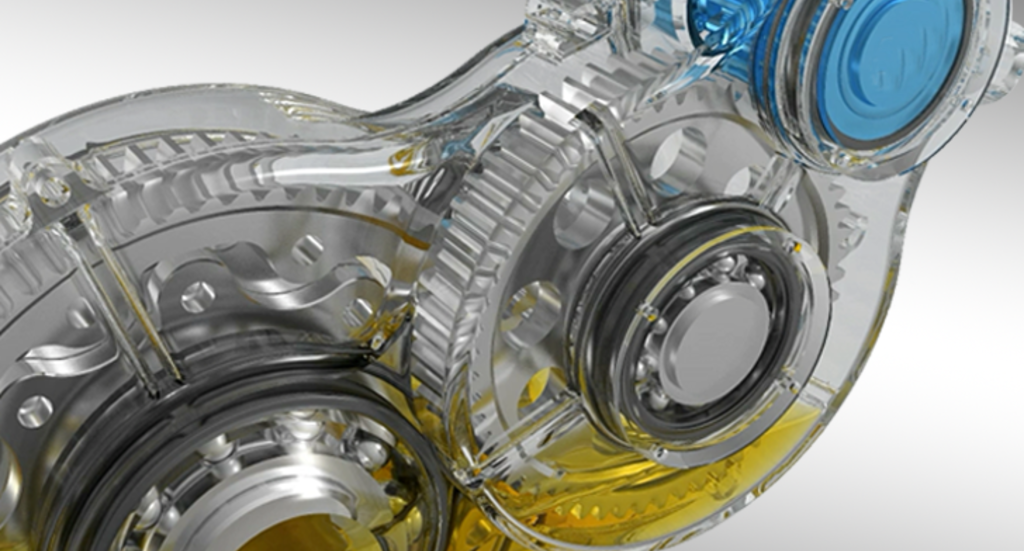

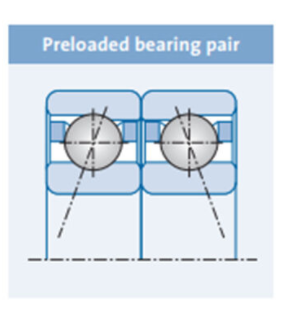

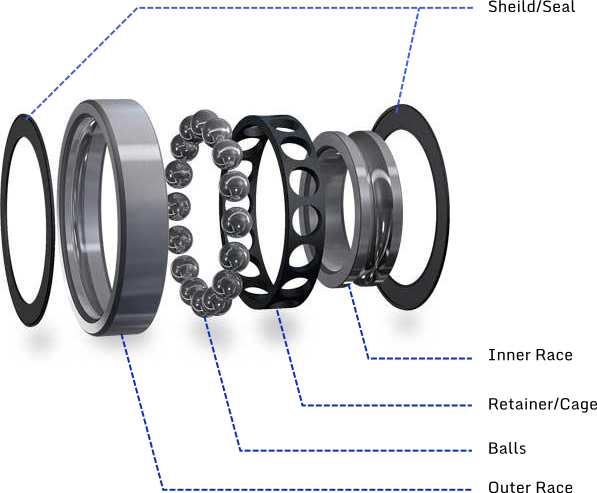

Bearing is an important part of mechanical rotation, and its stiffness and working temperature will directly affect the bearing efficiency on the mechanical operation. In order to provide the rotation accuracy of the bearing, increase the rigidity of the bearing device, and reduce the vibration of the shaft when the machine is working, the preloaded rolling bearing is often used, such as the spindle bearing of machine tool. The bearing ...

TBB family is getting bigger and bigger. The only constant 犀利士 is the smile on our faces, and sincerity to our clients....

Since the second half of 2020, affected by multiple factors, bearing raw materials have increased significantly. At the end of the year, the price of bearing steel has increased by nearly 30%. Bearing steel has a net increase of 1300 yuan per ton, while bearing steel pipe has a net increase of 2800 yuan per ton. By the end of January 2021, bearing steel has increased by another 300 yuan per ton, with an increase of 35.6%. Coupled with t...

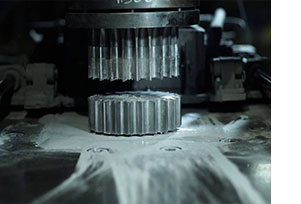

Powder metallurgy (PM) is a technology that uses metal powder or nonmetal powder or its mixture as raw materials to manufacture metal materials, composite materials and various types of products through forming and sintering. Its three core elements are technology, materials and equipment, which are widely used in transportation, machinery, electronics, aerospace and other important industrial fields. It is the most potential and dynami...

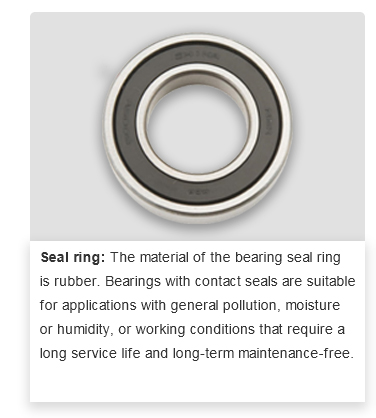

Sealing devices can generally be divided into static seals (fixed seals) and dynamic seals (rotating seals). The former is called gasket seal, and the latter is called gasket seal....

Sealing is indispensable for bearings. Sealing can not only prevent the leakage of lubricant, but also prevent the invasion of harmful foreign bodies. Otherwise, it will cause the abrasive wear of the bearing raceway, reduce the service life of the bearing, and make the bearing parts corroded by harmful gas and moisture, and accelerate the aging of the lubricant. ...

These News About Bearing Industry You Must Know in 2021...

The number of electric and hybrid cars on the road is on the rise leading to innovation in the bearings used on the production line. Nobody could have predicted the huge number of electric and hybrid cars on the road worldwide today....