Scoring and wiping are two common causes of oil-film bearing failure. Scoring is characterized by circular parallel grooves on the bearing lining surface and are heavier at the load zone. Wiping results in the displacement of babbitt from one location to another. If you see air-moving equipment, chances are oil-film bearings lie at the heart of centrifugal and axial fans. Serious damage can result to the entire unit should these bearing...

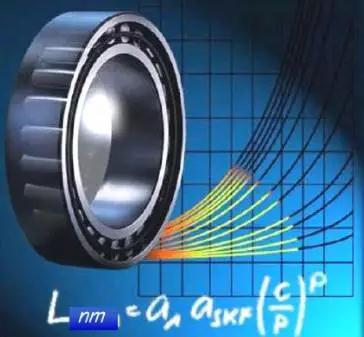

How long will a bearing last? Standardized life equations help to answer. Relative effects of contamination and lubrication condition on bearing life with different load levels. Experience shows seemingly identical rolling bearings operated under identical conditions may not last the same amount of time. In most cases, it is impractical to test a statistically significant number of bearings, so engineers rely on standardized bearing-lif...

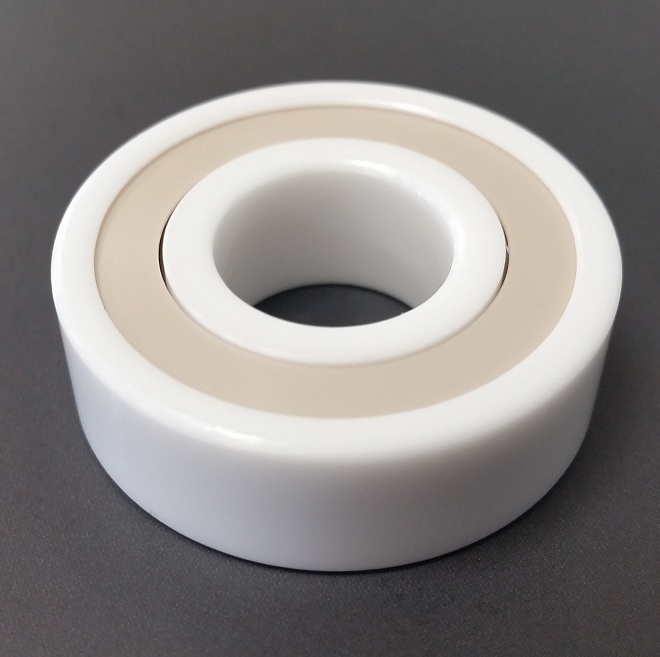

Approximately 27,000 ceramic tiles cover the exterior of the NASA Space Shuttle—a reusable spacecraft that carries astronauts in a low orbit around Earth. Acting as a thermal barrier to the 1,650°C generated by atmospheric re-entry, the tiles illustrate the impressive resistance of ceramic materials. The impressive properties of ceramics are also being used in bearings. Ceramics are primarily used in bearings due to the material’s ...

Thrust bearing are a type of rotary bearing that permits rotation between parts and is designed to support a high axial load while doing so (parallel to the shaft). 犀利士 We specializes in miniature thrust bearings and small thrust bearings. Our ball thrust bearing metric series start with bores as small as 2.0 mm with flat raceways and 3.0 mm with grooved raceways with outside diameters of 6.0 mm and 8.0 mm respectively. Some im...

Small to midsize OEMs that now source rotating-equipment products and services through multiple vendors may want to consider using a dedicated, local distributor. Distributors have access to a broad product range and can readily supply related items such as bearings, electric motors, belts, and gearboxes. This simple tactic of consolidating your supply source will immediately provide tangible benefits, including one-stop shopping, a sin...

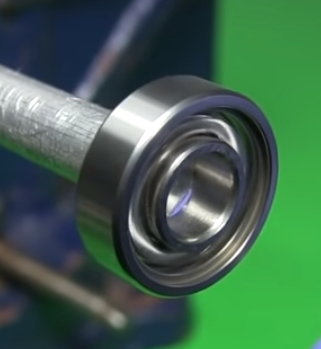

Get out the surgical gloves when working around the most fragile of bearings. Dynaroll miniature ball bearings make a dime look large. (Left)Grooves make room for adhesive to flow without raising runout. (Right)Make sure the shoulder rim clears the opposing ring when locating a bearing against a shoulder in a mating part: Maximum shaft shoulder diameter = Outer ring land diameter – clearance Minimum housing diameter = Inner ring l...

Limiting speed values for instrument bearings are almost impossible to determine. However, generalizations may be made. Bearing size: Highest speeds may be obtained with the smallest bearing. However, extremely small miniature bearings usually have a thin, weak retainer and their maximum speed is less than medium-size miniatures. Load: Limiting speed is directly affected by the magnitude of applied load. Heavy loads result in ...

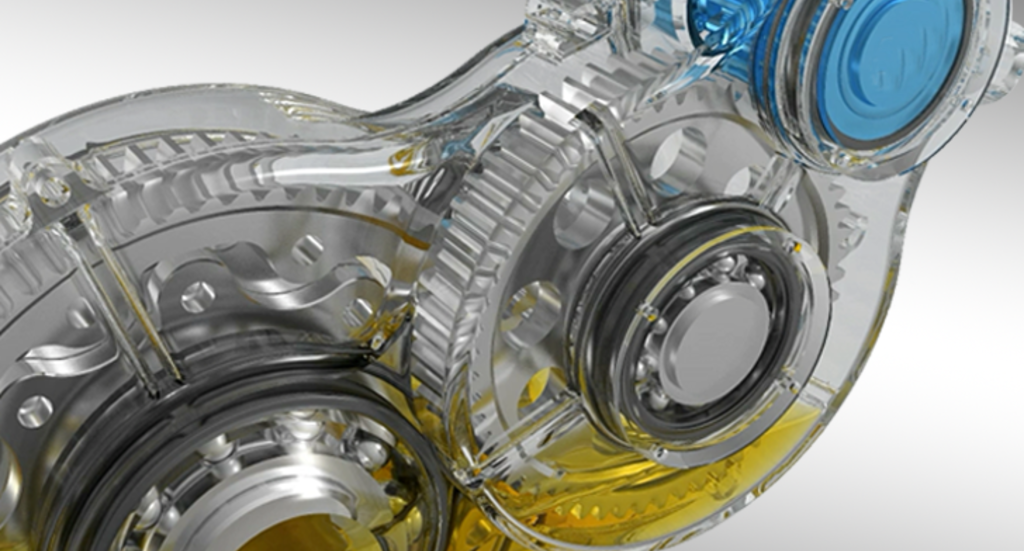

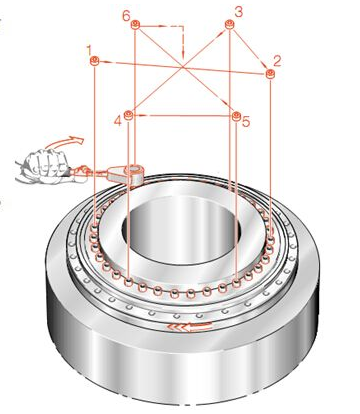

Heat is generated either by shearing of the oil film or by rubbing contact. In hydrostatic and hydrodynamic bearings, heat generation at running speeds is the result of oil shear, and the amount of temperature rise can be estimated if oil viscosity and shear rates are known. Temperature can be regulated by controlling the oil flow through the bearing or by using external cooling. Heat is generated either by shearing of the oil film or b...

Bearing torque is the moment required to overcome internal friction to start or maintain rotation of one ring while the other is stationary. Torque or friction generally increases when: Bearing size is increased because a larger ball and retainer must be moved. Load is increased because of greater deformation and resistance to rolling motion. Speed is increased because of increased lubricant drag. Lubrication type is a critical torque f...

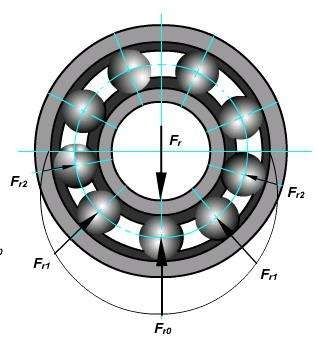

In some applications, allowable load seriously influences selection. Major variables affecting load capacity are ball size and number and internal geometry of the bearing. Static:犀利士 Primary consideration is given to static ratings. A bearing may be deformed permanently by high loads on nonrotating bearings or severe instantaneous loads on rotating bearings. Radial static capacity for instrument bearings is defined a...