A GROWING NUMBER OF “BARGAIN” BEARINGS&犀利士 nbsp;are being brought into the Heavy Duty Truck and Trailer marketplace by bearing brokers whose primary emphasis is on price. They ignore the critical issues of product integrity, performance, and supplier support. Initially the price has some attraction, but testing performed by Hyatt and other major suppliers has proven that a much superior performance is achieved from a quality product provided by a reputable manufacturer.

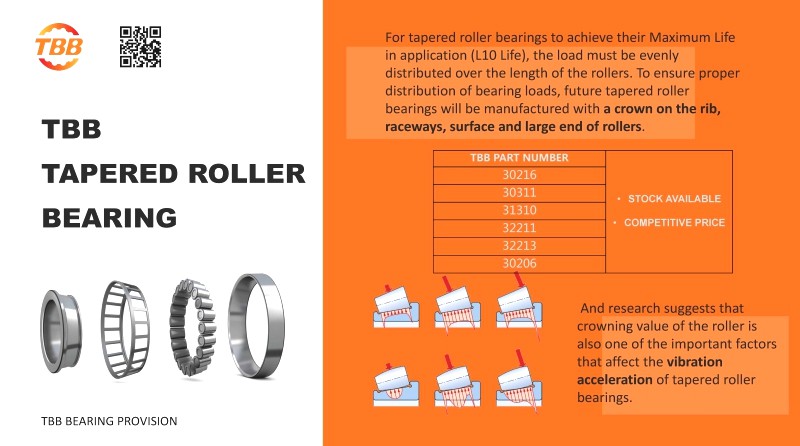

For tapered roller bearings to achieve their Maximum Life in application (L10 Life), the load must be evenly distributed over the length of the rollers. To ensure proper distribution of bearing loads, Hyatt Tapered Roller Bearings are manufactured with a crown on the raceways and rollers.

In our experience, the “bargain” products rarely have raceways and rollers that are crowned. Frequently the components have concave contact areas, generating even higher stresses within the bearing and promoting early catastrophic failure. Bearing brokers will state that their products conform to American Bearing Manufacturers Association (ABMA) specifications. These standards, however, only relate to the external dimensions of the bearing and its compatibility with the wheel hub and spindle.

If you want a quality product which is going to provide years of uninterrupted service, then it pays to install the bearings which have become the industry standard based on performance value.

- When cup and cone are perfectly aligned, the load is evenly distributed across the length of the roller, even with no crown.

- Under heavy loads the wheel end component deflects in operation causing bearing misalignment. When cup and cone are misaligned, the load is concentrated at one end of the roller. The cup and cone are unable to adjust to compensate for the misalignment. This concentration of stress will lead to early bearing failure, specifically raceway and roller spalling and peeling in truck and trailer applications.

- When cup and cone are misaligned, the load will be evenly distributed across the length of the roller. In this case, the cup, cone and roller are self-adjusting to compensate for the misalignment.

The General Bearing

2 Comments

te pressure on te bearing in no efen and te heat on te bearing is hiher

Right, very nice article