Full ceramic bearings have the characteristics of magnetoelectric insulation, wear resistance, corrosion resistance, oil-free self-lubrication, high temperature and cold resistance, which can be used in extremely harsh environment and special working conditions. Material ZrO2 has perfect properties such like suitable for low and high temperatures, high load capacity, corrosion resistance, nonmagnetic insultated and self-lubrication. Thus it suits for the specific applications which are not available for bearing steel and hybrid construction ceramic bearing materials.

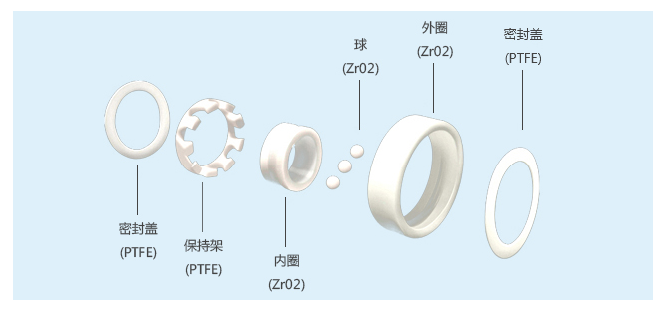

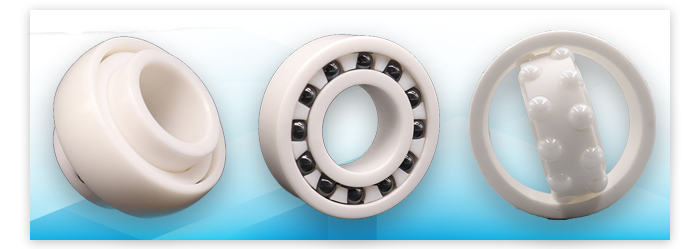

ZrO2 full ceramic bearings use zirconia (ZrO2) material for inner/outer rings as well as balls/rollers, retainer material is PTFE as standard, glass fiber reinforced nylon 66(PA66-25), PEEK, PI, SUS316, CU are also used as ceramic bearing retainers.

Hybrid ceramic ZrO2 bearings use ceramic ZrO2 balls/rollers (weigh up to 40% less than steel balls/ rollers, depending on size, the lighter ball/roller allows the bearing to spin faster, use less energy to maintain its speed) and steel inner/outer rings(Normally chrome steel GCr15 or stainless steel AISI440).

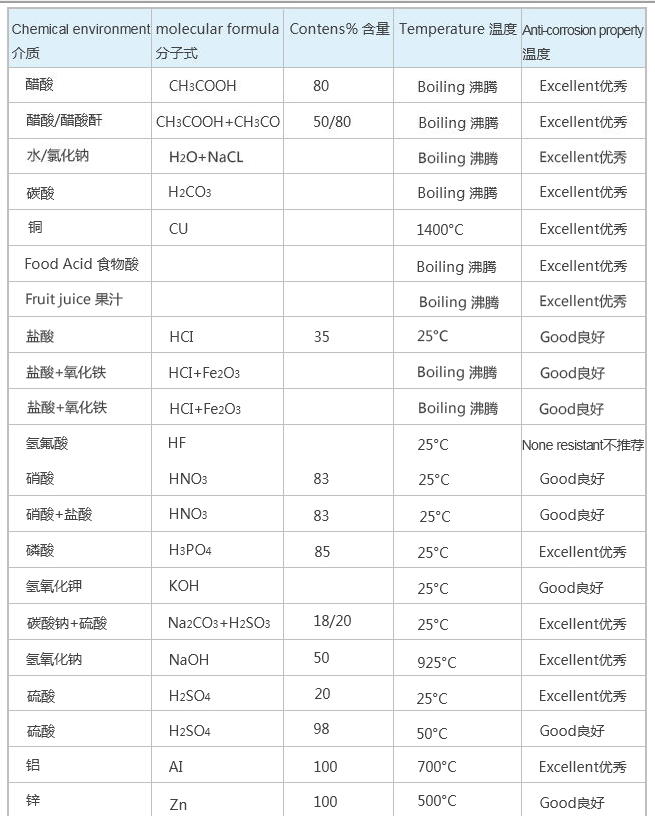

Anticorrosion properties of ZrO2 bearing

Application: Food conveyor, Non-magnetic and insulation condition, Dust condition, Vacuum condition, High-temperature condition, Clean condition, Corrosive condition, Food industry, Linear guideway, etc.

<壯陽藥 !– /wp:image –>

Description: Full and Hybrid Ceramic Bearing ZrO2

Cage: PTFE/PEEK/PI/PA66-25/SUS316/CU

Version: Natural white

Note: Zirconia(ZrO2) is a cost-effective alternative to Si3N4, it also has the advantage that the thermal expansion is similar to that of steel, which means that a shrink fit is not required as expansion differences between the bearing housing and a steel shaft do not occur.

On request: with cage/without cage

Safety: Reacts with concentrated hydrochloric acid, nitric acid and sulphuric acid

ZrO2 Deep Groove Ceramic Ball Bearings: Deep groove ball bearings mainly take radial load as well as take moderate axial load. With less coefficient of friction, high limiting speed, large size range and shape variations of diversity.

ZrO2 Self-aligning Ball Ceramc Bearings: With two structures of bore cylindrical and conical, retainers made of steel sheet or synthetic tesins, the bearings are characteristic of their spherically formed outer ring raceways allowing for misalignment within 3 degree between inner ring and outer ring, so as to compensate concentricity and deflection errors.

ZrO2 Thrust Ball Ceramic Bearings: This type of bearings is separable, which can only carry axial load, the single direction bearings of them can only carry axial load in one direction, while the double can carry alternating axial load in either directions. Before using they have to be preloaded. The thrust ball bearings are used in lathe centers, automobile clutches, reducers etc. The double direction angular contact thrust ball bearings are suitable for machine tool spindles, while the single are used to support ball screws.

ZrO2 Angular Contact Ball Ceramic Bearings: Angular contact ball bearings are able to support radial load and axial load. As single row angular contact ball bearings can only support axial load in single direction, matched bearing mounting is often adopted to them. As matched pairs of bearings, preload for them is more conevnient.

ZrO2 Spherical Ceramic Bearings

3 Comments

Can I get the Catalogue?

What’s the performance differences upon different cage materials? Like PTFE, PEEK…

Have you done a life test of this kind of bearing?