● Significance & Application of CQI-9 HTSA The North American automotive association AIAG (Automotive Industry Action Group) is the publisher of the CQI standards (Continuous Quality Improvement). CQI-9 Heat Treatment System Assessment is a self-assessment of the heat treatment system and must be carried out at least once a year.This standard is an appendix to ISO TS 16949 (IATF 16949) under ?customer-specific requirements“ and is valid for all automotive suppliers globally that have entered into a contractual agreement regarding purchasing, supply and quality throughout the supply chain. CQI standards are used in several typical situations as below: Customer’s request, as a supplement of product standardsApplicable to the whole auto Customer’s request, as a supplement of product standards Applicable to the whole automotive industry Assessment of manufacturer to comply with automotive industry standards Applicable to all?heat treatment enterprises ● Structure, Content and Elements of the CQI-9 Questionnaire ● Process Tables of the CQI-9 HTSA More about CQI – Continuous Quality Improvement? More about CQI-9HTSA?

There’s always a chance that things break. Same with bearings, but it doesn’t mean that we can’t prevent those issues beforehand to avoid further troubles. The below chart will show you how bearing failure comes and what we can do to prevent it ahead of time to make your application much stronger. With the above knowledge, you don’t have to wait for the symptoms of a bearing failure before you take actions, which can help save your time and money. We TBB Bearing Provision is always here happy to provide you with assistance and support upon your request.

Bearing in ABEC-7(P4) or ABEC-1(P0) for my application? ●What does Bearing Precision mean? When dealing with rolling bearings, precision is described by tolerance classes which include dimensional accuracy and running accuracy.it is regulated by ISO or other related standards. Dimensional Accuracy includes (the items related to the installation of shaft and outer shell): 1. Allowable deviation (acceptable values) for bore diameter, outer diameter, width and assembled bearing width 2. Bore diameter uniformity as seen in chamfer dimensions 3. Allowable inner ring tapered bore deviation and shape error 4. Average bore diameter variation 5. Outer diameter variation 6. Average outer diameter unevenness 7. Raceway width and height variation (for thrust bearings) Running Accuracy includes (items related to the runout of the rotator): Acceptable values for inner and outer ring radial runout and axial runout Acceptable values for inner ring side runout, and outer ring outer diameter runout Permissible variation of raceway thickness of thrust bearing Permissible deviation and variation of tapered hole Permissible variation of inclination of the outer ring surface Here I attached the comparison table from different countries: The applicable accuracy levels are different according to different types of bearings. The following table shows different types of bearings and their…

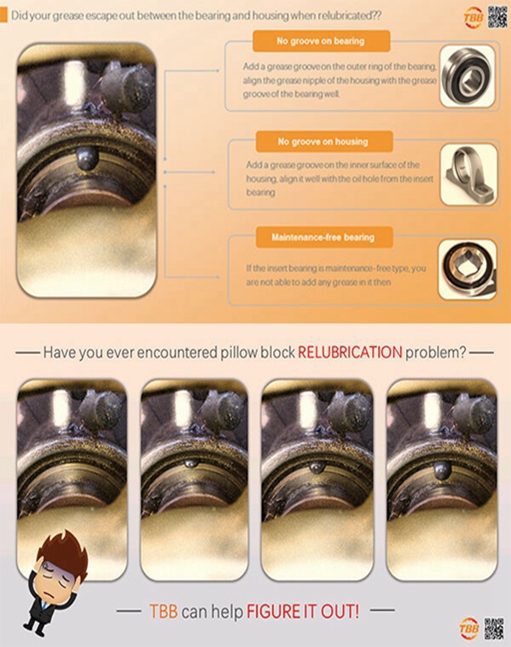

● Functions of a lubricant If rolling bearings are to operate reliably they must be adequately lubricated to prevent metal-to-metal contact between the rolling elements, raceways and cages. Separation of the surfaces in the bearing is the primary function of the lubricant, which must also inhibit wear and protect the bearing surfaces against corrosion. In some applications the lubricant is also used to carry away heat. The choice of a suitable lubricant and method of lubrication for each individual bearing application is therefore important, as is correct maintenance. Lubricants for rolling bearings serve the following functions: * Separate the rolling contact surfaces in the bearing; * Separate the sliding contact surfaces in the bearing; * Protect highly finished bearing surfaces from corrosion; * Provide sealing against contaminants (in the case of grease); * Provide a heat transfer medium (in the case of oil). ● Re-lubrication of pillow block The purpose of any bearing, housed or not, is to reduce the amount of friction between connected or interacting components. The right bearings also reduce the amount of wear-and-tear on the equipment. This, in turn, increases the longevity and operational capabilities of the machinery which requires some form of lubrication. A single…

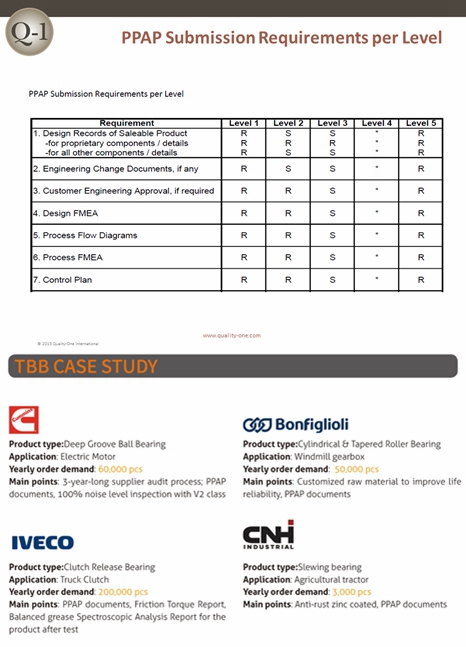

●What is PPAP? PPAP is the abbreviation of Production Part Approval Process, a valuable tool for establishing confidence in component suppliers and their production processes. Initially, PPAP was utilized by the automotive and aerospace industries. PPAP is now being utilized by several industries to improve communication and provide quality products. Within the automotive industry, the ultimate resource for PPAP information is the manual published by the Automotive Industry Action Group (AIAG). PPAP defines the approval process for new or revised parts, or parts produced from new or significantly revised production methods.?It verifies that the supplier understands all customer engineering design specifications and requirements and that the process is capable of consistently producing product meeting those requirements during an actual production run at the quoted production rate. ●How to perform PPAP? The PPAP process consists of 18 elements that may be required for approval of production level parts. Not all of the elements are required for every submission. There are five generally accepted PPAP submission levels. A, 18 elements of PPAP: 1. Design RecordsA copy of the drawing. If the customer is responsible for designing, this is a copy of customer drawing that is sent together with the Purchase Order (PO)….

Rolling element bearings are available in a variety of types, configurations, and sizes. When selecting the correct bearing for your application, it is important to take these factors below into consideration. 1. Operating conditions and operating environment1) Function and construction of components to house bearings2) Bearing mounting location3) Bearing load (direction and magnitude)4) Rotational speed5) Vibration and shock load6) Bearing temperature (Ambient temperature/temperature rise)7) Operating environment (potential for corrosion, degree of contamination, extent of lubrication) 2. Bearing type and configuration1) Dimensional limitations2) Bearing load (magnitude, direction, vibration, presence of shock load)3) Rotational speed4) Bearing tolerances5) Rigidity6) Allowable misalignment of inner/outer rings7) Friction torque8) Bearing arrangement (fixed side, floating side)9) Installation and disassembly requirements10) Bearing availability and cost 3. Bearing dimensions1) Design life of components to house bearings2) Dynamic/static equivalent load conditions3) Safety factor4) Allowable speed5) Allowable axial load6) Allowable space 4. Bearing tolerances1) Shaft run-out tolerances2) Rotational speed3) Torque fluctuation 5. Bearing’s internal clearance1) Material and shape of shaft and housing2) Fit3) Temperature differential between inner/outer rings4) Allowable misalignment of inner/outer rings5) Load (magnitude, nature)6) Amount of preload7) Rotational speed 6. Cage type and material1) Rotational speed2) Noise level3) Vibration and shock load4) Momentary load5) Lubrication type and method 7. Lubricant, lubrication method, sealing method1) Operating temperature2) Rotational speed3) Lubrication…