TBB Case of Needle Roller Needle Roller Bearing Used in JAC Gearbox MF70B Heavy Duty Cam Followers – Stud Type Track Rollers Comments from TBB Customer

Case No. 1 TBB optimized products can work under higher load rating with longer lifetime. Case No. 2 Case No. 3 Bearing Durability Test Comparison — Needle Roller Bearing HK1010Application: Automotive automatic gearboxTest purpose and method: Bearings run a test continuously under constant radial load. The durability test component level test were run on both TBB and INA, the test results:1, Total test time is about 2870hours and 3.42 times to the L10 lifetime requirement2, No abnormal failure phenomenon was found3, No cracks, spalling or pitting were found on the outer surfaces4, No damage on the components. Both TBB and INA bearings passed the durability test.

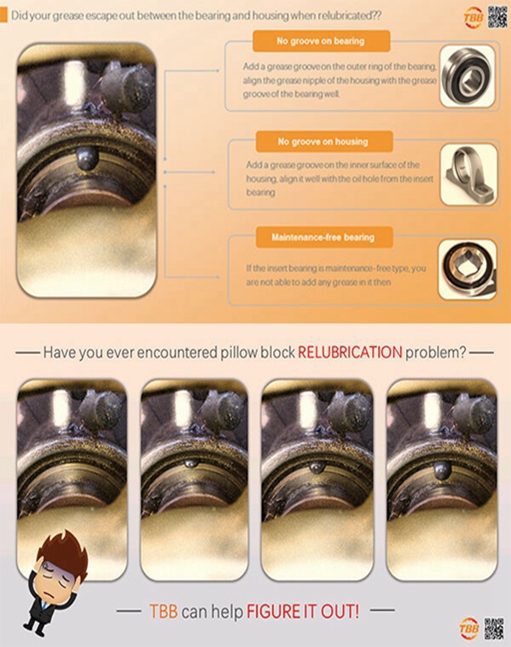

● Functions of a lubricant If rolling bearings are to operate reliably they must be adequately lubricated to prevent metal-to-metal contact between the rolling elements, raceways and cages. Separation of the surfaces in the bearing is the primary function of the lubricant, which must also inhibit wear and protect the bearing surfaces against corrosion. In some applications the lubricant is also used to carry away heat. The choice of a suitable lubricant and method of lubrication for each individual bearing application is therefore important, as is correct maintenance. Lubricants for rolling bearings serve the following functions: * Separate the rolling contact surfaces in the bearing; * Separate the sliding contact surfaces in the bearing; * Protect highly finished bearing surfaces from corrosion; * Provide sealing against contaminants (in the case of grease); * Provide a heat transfer medium (in the case of oil). ● Re-lubrication of pillow block The purpose of any bearing, housed or not, is to reduce the amount of friction between connected or interacting components. The right bearings also reduce the amount of wear-and-tear on the equipment. This, in turn, increases the longevity and operational capabilities of the machinery which requires some form of lubrication. A single…

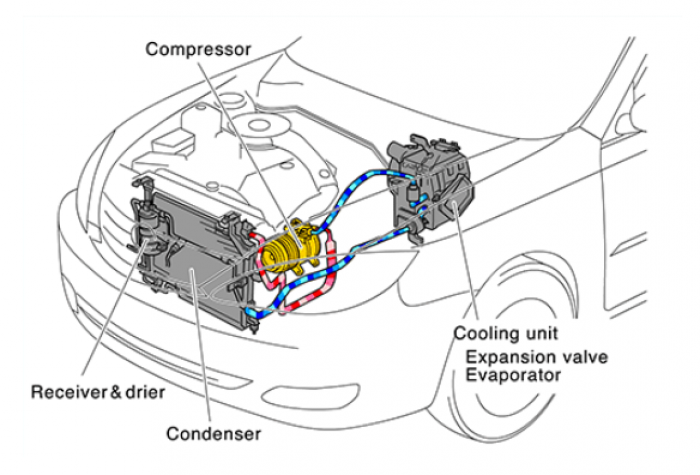

Much like a heart in a human body, the compressor circulates the system’s lifeblood, in this case the refrigerant, that is vital to the proper operation of the air conditioning (A/C) system.The world-leaders of car air-conditioning compressors, such as Toyota Motor Corporation, Daimler AG, General Motors Company (GM), Volkswagen AG and Hyundai Motor Company. Car Air-Conditioning Mechanisms Liquid (refrigerant) is cycled throughout a sealed air conditioning system in a repeated process of vaporization (evaporation), liquefaction, and re-vaporization. It is necessary for a gas to give off heat to liquefy (condense). If the refrigerant gas is pressurized, and the pressure is increased, it becomes comparatively easier to liquefy. TYPES OF COMPRESSOR 1, Swash Plate Type (Fixed Displacement) This piston is constructed from the components shown in the illustration.The pistons move back and forth when power from the engine causes the shaft and swash plate to rotate. One piston is comprised of cylinders on both sides. The ends of the piston intake pressurize and discharge refrigerant. 2, Vane Type (Fixed Displacement) This compressor is constructed from cylinders and five vanes built into the rotors, as well as two discharge valves and front and back side plates.The five vanes rotate in tandem with the rotors…