With the development of mechanical manufacturing industry towards high precision and high speed, the application range of bearings is more and more wide, and the performance requirements of bearings are also higher and higher, especially in some special working environment, metal bearings can not adapt to the demand, or even can not work at all. Because of its low density, high modulus of elasticity, low coefficient of linear expansion, wear resistance, high temperature resistance, corrosion resistance and other excellent properties, ceramic material has become an ideal material for high-speed manufacturing of precision bearings. Advantages and Characteristics of Silicon Nitride Ceramics Although silicon nitride is not the hardest and the most tough material in industrial ceramics, it is considered to have the best mechanical and physical properties in high performance bearing applications. Heat ResistanceGenerally, when the service temperature of steel bearings exceeds 120 ℃, the hardness will decrease and the rolling life will also decrease. Silicon nitride has good temperature characteristics, especially suitable for high temperature environment. Centrifugal ForceThe density of silicon nitride is about 3.24 × 103kg / m3, while the density of bearing steel is about 7.8 × 103kg / m3, which is only about 40% of the density…

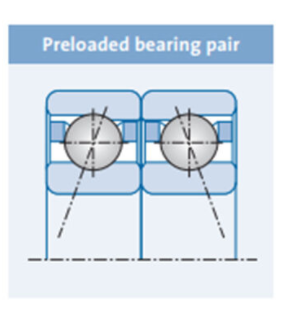

Bearing is an important part of mechanical rotation, and its stiffness and working temperature will directly affect the bearing efficiency on the mechanical operation. In order to provide the rotation accuracy of the bearing, increase the rigidity of the bearing device, and reduce the vibration of the shaft when the machine is working, the preloaded rolling bearing is often used, such as the spindle bearing of machine tool. The bearing stiffness is the force required to produce a unit deformation. The elastic deformation of rolling bearing is very small, which can not be considered in most machines. However, in some machines, such as machine tool spindle, bearing Stiffness is an important factor, in which case generally cylindrical roller bearings and tapered roller bearings should be selected. Because these two kinds of bearings are in line contact with the raceway when they are under load, they have small elastic deformation and good stiffness. All kinds of bearings can also be preloaded to increase the support stiffness. Such as angular contact ball bearing and tapered roller bearing, in order to prevent shaft vibration and increase support stiffness, a certain axial force is often applied in advance during installation to make them compress…

Powder metallurgy (PM) is a technology that uses metal powder or nonmetal powder or its mixture as raw materials to manufacture metal materials, composite materials and various types of products through forming and sintering. Its three core elements are technology, materials and equipment, which are widely used in transportation, machinery, electronics, aerospace and other important industrial fields. It is the most potential and dynamic branch of new materials science.

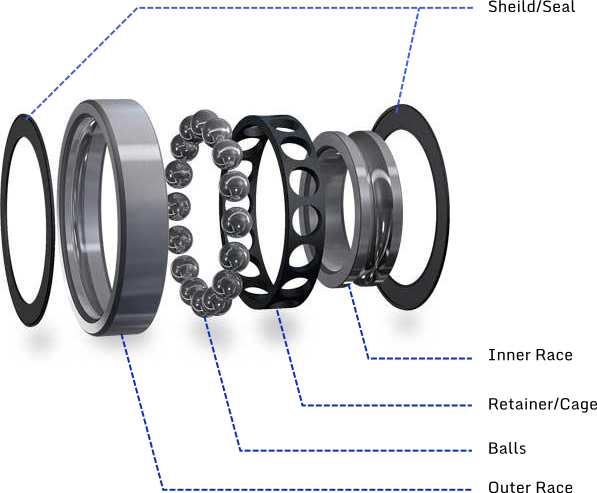

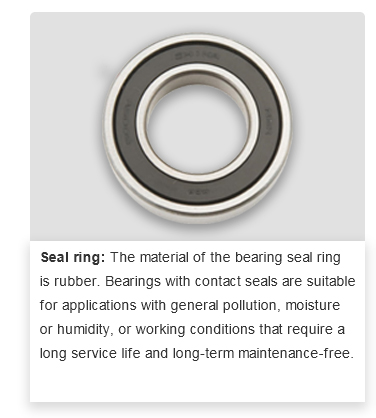

Sealing devices can generally be divided into static seals (fixed seals) and dynamic seals (rotating seals).

The former is called gasket seal, and the latter is called gasket seal.

Sealing is indispensable for bearings. Sealing can not only prevent the leakage of lubricant, but also prevent the invasion of harmful foreign bodies. Otherwise, it will cause the abrasive wear of the bearing raceway, reduce the service life of the bearing, and make the bearing parts corroded by harmful gas and moisture, and accelerate the aging of the lubricant.

TBB can provide various types of maintenance-free spherical plain bearings.

“Maintenance-free” is an industry-wide term used to describe plain bearings and rod ends with self-lubricating sliding contact surface combinations.

These so-called maintenance-free bearings and rod ends offer a number of advantages for OEMs and end users alike. These advantages, which include minimal maintenance and reduced lubricant consumption, quickly compensate for the difference in the initial purchase price. And of course, the impact that maintenance-free bearings have on the environment is an added benefit.

Here are some examples of applications in which spherical roller bearings might be used: Vibration Screen Bearing, Wind turbine bearings, Papermaking mills bearings, Continuous Caster bearings & etc.

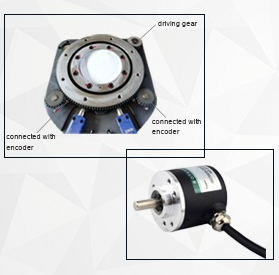

Here you can find some application cases for slewing bearings used in indoor EVs

Spherical Roller Bearings have many different structures, such as CC type, CA type, E type from SKF and MA type, MB type, E1 type from FAG. Now let me give you a detailed introduction of the difference between these designs.