Massive rotors in hydroelectric generators, large ball mills, rolling mills, large electric motors, and steam and gas-turbine generators normally operate with great efficiency on oil films in sleeve and thrust bearings. But trouble arises when rotational speed is too low, as it is at starting and stopping, to generate a complete oil film. Then frictional drag and wear increase with metal-to-metal contact between the bearing and rotating shaft.

So, how do engineers minimize friction and wear at low speed? The answer is hydraulic lift with pockets that provide oil-film lubrication by lifting a slow-turning shaft off its bearing surface.

At low speeds, an auxiliary pumping system with typical pressures of 1,000 to 4,000 psi can float the rotor on an oil film. Once rotational speed reaches the 20 to 30-rpm range, a hydrodynamic bearing operating-fluid film is usually established and can take over the bearing task from the lift pump.

To use additional hydraulic lift, designers must carefully calculateoil-feed rates, oil pressures, and bearing lift height. Although the authors suggest engineers follow the general guidelines that follow 犀利士 in both journal and thrust bearings, consulting manufacturer data for specific recommendations is also important.

Journal bearings

In sleeve journal bearings, pressurized hydraulic oil is supplied through one or more pockets or grooves. The pocket area is small, usually just 3 to 8% of the projected bearing area.

Applications with high loads or large bearing areas, such as large steam-turbine bearings, require special pocket geometries. Small flared-edge, elliptical pockets arranged axially along the bottom centerline help high-pressure oil penetrate between bearing and shaft surfaces.

Such geometries let lift-off action start at lower pressures, extend the pressurized zone to an area of lower elastic contact pressure between the bearing surface and journal, and minimize the axial length of the journal surface that might be scored by any dirt that collects in the pockets.

Another type of geometry includes one or two parallel pockets with long axes perpendicular to the circumference. This arrangement keeps oil from discharging circumferentially to one side.

Journal bearings need to be fed oil with sufficient hydraulic pressure to initiate lift-off. This minimum pressure is called breakaway pressure. Once oil begins to penetrate around a lift pocket, it spreads over the surrounding surface to complete the lift.

Research shows that with elliptical oil-lift pockets, breakaway pressure, Pba, can be estimated from Elwell’s equation (see Resources):

where W = total load on the bearing, lb; D = bearing bore diameter, in.; n = number of pockets along the bottom center line; A = area of a single lift pocket, in.2; and kba = dimensionless breakaway parameter, typically 3.

Fuller (see Resources) developed a method of estimating the oil-feed volume, Q, in in.3/sec required to support the shaft with a minimum oil-film thickness, hm, in inches:

where C = radial clearance, in.; R = bearing bore radius, in.; μ = oil viscosity, lbf-sec/in.2 or reyns; and ε = eccentricity ratio, (1 – lift height)/C.

At this oil-feed volume, the pressurized film extends over the bearing length, either with lift pockets or extended pocket area. Larger pocket areas provide more initial lift, and lower mean hydraulic feed pressures are needed for breakaway.

After lift-off, an equilibrium feed pressure, P, in psi is needed to generate a minimum oil film thickness of 0.002 to 0.010 in. The following expression, modified from Fuller’s work, estimates the required pressure:

where B = ¾ L, and L = axial length, in.

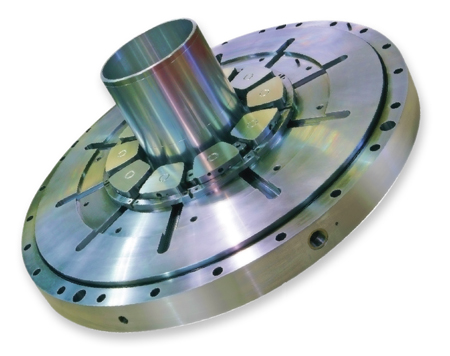

Thrust bearings

Thrust bearings typically have flat bearing surfaces whether they are designed with pivoted or spring-supported pads. In these bearings, central lift pockets can provide hydraulic lift. Lifting oil spreads out from such a pocket when oil-feed pressure is about 500 psi higher than the contact pressure around the pocket.

To determine the equilibrium hydraulic supply pressure, Ps, in the pocket needed to balance the load in a thrust pad, use the following expression from Khonsari and Booser (see Resources). It is derived from the concept of an equivalent circular pressure field.

where W = load, lbf, on a single bearing segment; R1 = outside radius, in.; and R2 = the pocket radius, in.

The area, A, of a conventional wedge shape can be approximated by the product of the segment radial length, B, and the length of the outer arc, L, both in in. This can be converted to a circular area with outside radius, R1:

A = B × L ≈ π × R12

R1 ≈ (BL/π)0.5

Substituting this in the above equation gives:

For bearings with circular segments, estimate the feed-oil volume, Q, in in.3/sec, needed to maintain a lift height of h in inches with the following expression:

where μ = oil viscosity, reyns. Revising this equation for a conventional wedge-shape segment based on the equivalent area, we get:

Additional considerations

Tailoring the lift pocket shape and size to an application can improve lift performance. Choose an elliptical shape with the long axis in the direction of rotation. The shape should straddle the bottom centerline in journal bearings so it doesn’t induce shaft rotation. Larger pockets and flared edges increase lift area and cut the oil pressure needed to generate lift.

The location and number of pockets is also important. Limit the axial spacing between lift pockets along the bottom of a sleeve bearing to about one-fourth of the journal diameter. For flat, pivoted thrust bearings, stick with a single central pocket in each segment.

In journal bearings, rougher surface finishes ease ingress of pressurized oil for the initial break-away lifting action. However, minor wear during the life of a machine may smooth both the journal and bearing surfaces, removing the advantage of the tailored surface finish.

For both journal and thrust bearings, the initial lift-off pressure is several times higher than the equilibrium pressure required for slow-speed turning. A relatively small oil accumulator can supply high-pressure lift-off oil while keeping the overall pressurized-oil-supply system smaller, more efficient, and capable of providing sufficient pressure for running conditions after lift off.

And don’t forget to include effective check valves in the high-pressure feed lines. Otherwise oil from the bearing lift pockets will leak away, endangering normal hydrodynamic operation at higher running speeds. Backflow through check valves can also drive high-pressure hydraulic feed pumps backward and speed pump and drive wear. Relief valves can protect pumps from high-pressure back flow during startup.

Machine Design