I was once a piece of iron Coming through a great deal of difficulties Smelting from iron ore Until the billet is formed Continuously quenching from lots of processes Built me an indomitable and undau…

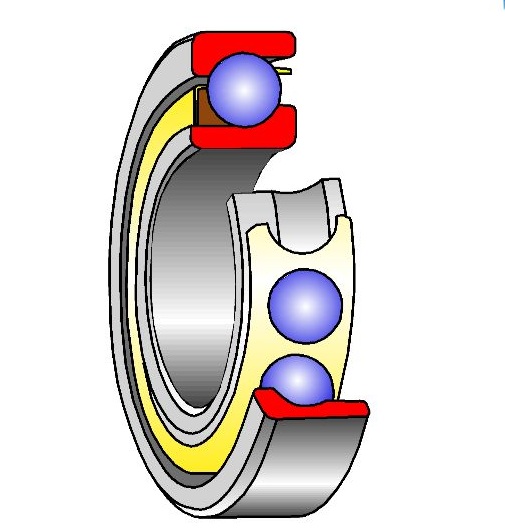

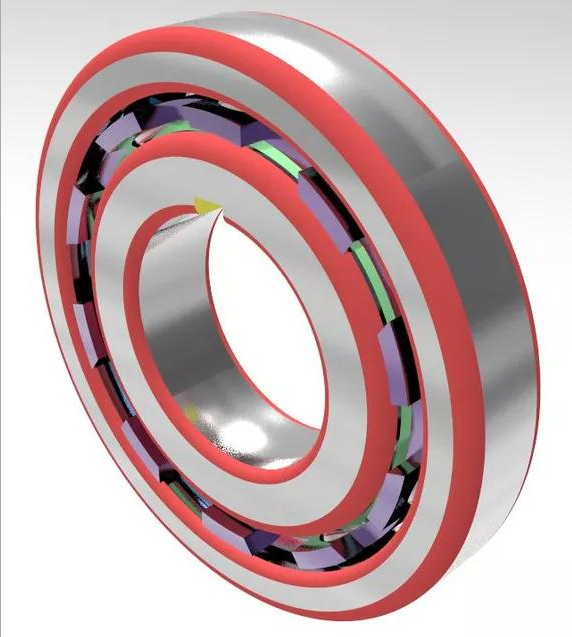

Design Variants To allow the bearings to accept the maximum number of balls, four point contact ball bearings are designed with split inner ring or with split outer ring so these bearings have two bas…

The PTC (Power Transmission and Control) Asia is an international trade fair for power transmission and control, which takes place once a year in Shanghai. Since its foundation in 1991 it has establis…

NSK has developed a new ultra-high-speed bearing ideal for electric vehicles, including battery electric, hybrid, and other new energy vehicles. The new bearing enables electric motors to operate at h…

Size from 2mm to 6m Bearings vary in sizes. The smallest “miniature bearing” in the world is with ID 0.6mm× OD 2.0mm× Thickness 0.8mm, which is used in micro motor. The large-size bearing,…

With the wide application of PWM and IGBT in motor, the problems caused by electromagnetic damage such as electric corrosion of bearing are more and more prominent. What causes electromagnetic damage …