Bearing packaging is an important step in bearing export. Improper packaging will bring many problems to bearing products and customers, resulting in unnecessary losses and trouble. Case example: Many bearing suppliers will encounter the problem of bearing packaging, especially large bearings. We learned about this case of bearing packaging complaint from a produc犀利士 er. Bearing type:24044CA.W33.S1,Product weight:39kg,Packaging method: three layers of wrapping packaging, 10 products stacked in a wooden box. Customer complaint: because the product is too heavy, 10 products are stacked in a wooden box, which can not be taken out and moved with the help of tools. Manual handling is not safe, and it is also easy to cause product damage. Large bearing packaging of TBB Therefore, for large bearings, packaging is very important. TBB was considerate in requiring suppliers to pack these large bearings, which not only solved the risk of bearing damage, but also eliminated customers’ safety concerns and greatly improved customers’ satisfaction. The following are the packaging methods and examples of TBB for large bearings. For bearings heavier than 40kg: they are wrapped in three layers. If multiple quantities are stacked in one wooden box, cross wooden frame shall be used to separate each product….

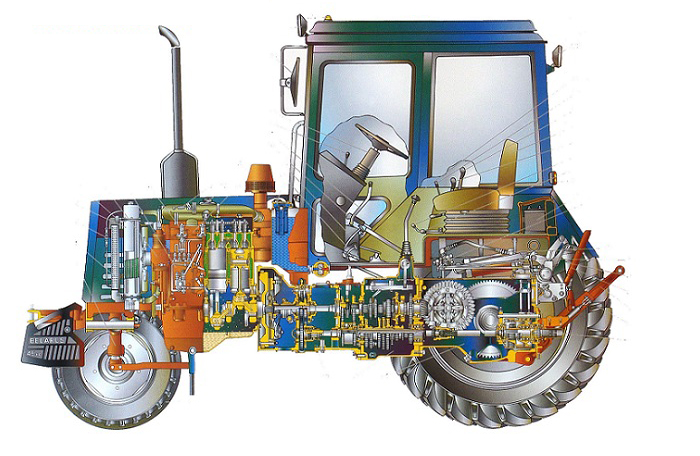

Agricultural engineering involves a wide range of machines, equipment and implements. This ranges from tillage machines, tractors, tedders and balers to powerful harvesting equipment such as forage harvesters or combine harvesters. Even if the machines are very different, the operating conditions are always harsh. In summer, dust and sand place high demands on the bearing seals, whereas during the spring and fall, moisture is a real challenge for farmers. Heavy soils test the mechanical strength of all machine parts to the limit. Constant vibrations and high shocks are loads that occur throughout the entire year. This is why the bearing supports in tillage mach犀利士 ines have to be particularly robust. Here we’ll make an introduction about tractor. Although there are many types of agricultural tractors with different structures, they are composed of three parts: engine, chassis and electrical equipment. Following are typical bearing arrangements in agricultural tractors: For further requests on bearings used in agricultural machinery, please make a direct contact with TBB