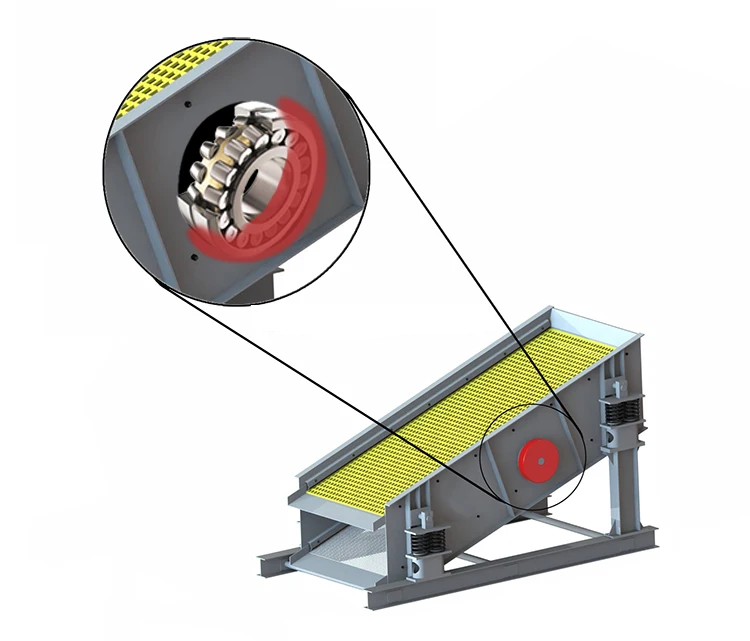

Vibrating screen bearing is a kind of special bearing designed for vibrating screen equipment, which can maintain stable operation under high-speed vibration, cyclic impact and heavy load conditions, withstand large radial and axial composite load, and at the same time, have the characteristics of high temperature resistance, anti-wear and long life.

Vibrating screen bearings convert the vibration energy of the screen body into smooth mechanical energy transfer through the rolling motion of the rolling body between the inner and outer rings. Its core functions include:

Supporting the screen body: Bear the dynamic load generated by the impact of materials in the screening process.

Reduce friction: Reduce energy consumption and wear by replacing sliding friction with rolling friction.

Buffer vibration: Absorb high frequency vibration energy, prolong the life of the equipment.

Vibrating screen bearings are usually composed of the following parts

- Inner ring: Fits with the shaft and transmits the load.

- Outer ring: Cooperate with bearing housing, support the inner ring.

- Rolling body (roller/ball): The core element of load transmission, common types include cylindrical roller, tapered roller, spherical roller.

- Cage: Separates the rolling bodies to reduce friction and wear.

- Seals: Prevent dust, moisture and lubricant leakage

Technical features

- Material selection

Bearing steel: High-carbon chrome steel (e.g. GCr15) or carburised steel for high strength and wear resistance.

Special materials: heat-resistant alloys are used in high temperature environments, and stainless steel or ceramic bearings are used in the food and pharmaceutical industries. - Lubrication and sealing

Lubrication: grease lubrication (high temperature resistant grease), some high-speed scenes use oil lubrication.

Sealing design: Multiple sealing structure (such as labyrinth + rubber sealing) to prevent dust and foreign matter from intruding. - Structural optimisation

Reinforced design: Increase the cross-section size or adopt special geometrical shapes to Improve fatigue resistance.

Preload control: Reduce vibration-induced loosening by adjusting the clearance.

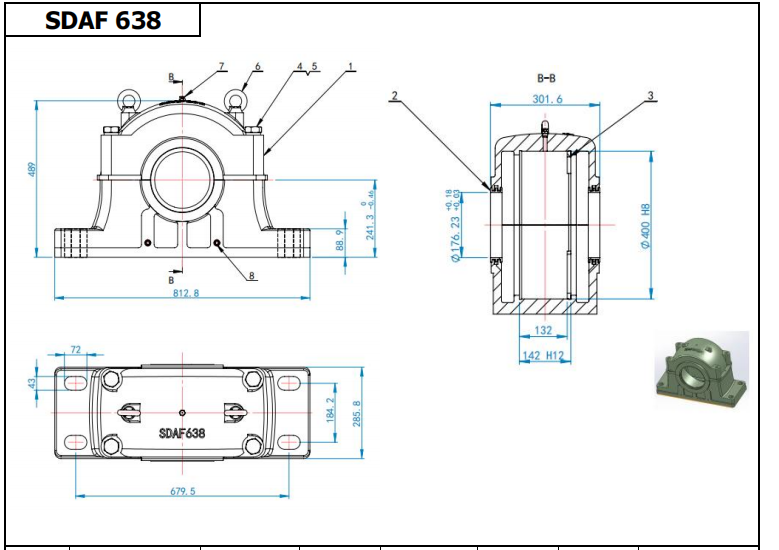

SDAF 638Recently we promote this bearing housing and the matching bearing. The price of that is very competitive, if you need it pls feel free to contact us.

- Product type: Split bearing housing

- Application information: For tight sleeve mounted bearings

- Matching bearing: Spherical roller bearing 22338MBW33

- Application: Mining machinery such as vibrating screens, crushers, blowers, etc.

2-1-1-1024x141.png)

No Comments