Bearing Selection Guide

The types, structures, and sizes of rolling bearings are diverse. In order to make the mechanical device play the expected performance, it is very important to choose the most suitable bearing.

To select a bearing, many factors need to be analyzed. The general sequence is as follows:

(1) Understand the operating conditions of mechanical devices and bearings, etc.

(2) Clear requirements for bearings

(3) Select the type of bearing

(4) Select the bearing configuration

(5) Select bearing size

(6) Select bearing specifications

(7) Installation method of selected bearing

The location of the bearing, the operating conditions, and the environmental conditions are the prerequisites for choosing a suitable bearing. For this, it is necessary to obtain the following data and information:

(1) Function and structure of the mechanical device

(2) Where to use the bearing

(3) Bearing load (size, direction)

(4) Rotation speed

(5) Vibration and shock

(6) Bearing temperature (ambient temperature, temperature rise)

(7) Ambient atmosphere (corrosive, clean, lubricating)

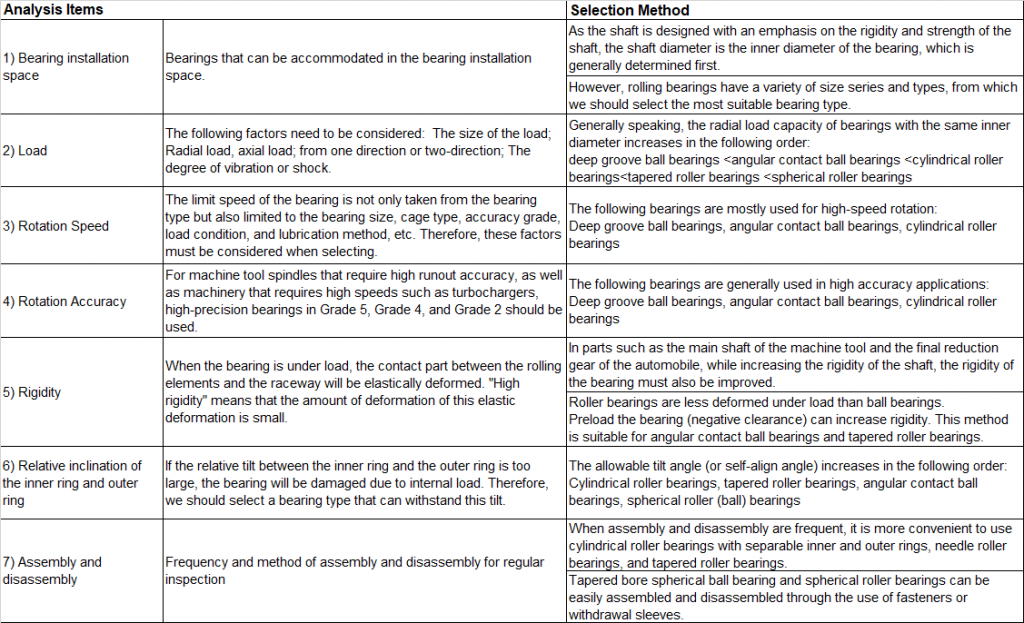

How to select the bearing type for your machine?

When selecting a bearing type, it is important to fully understand the operating conditions of the bearing. The following table lists the main analysis items:

One Comment

Common knowledge