TBB drawn cup needle roller bearings is formed with thin steel plate through precision punching with very sectional height and big load capacity. This kind of bearings are especially applicable to the big quantity production with economic demands.

Stable combination is used between the needle bearings and the bearing cage. No axle fixture is required. Even under high speed and heavy load condition, the bearing functions can be fully maintained. Furthermore, no lubricating for a long time is possible due to its high storage volume of grease.

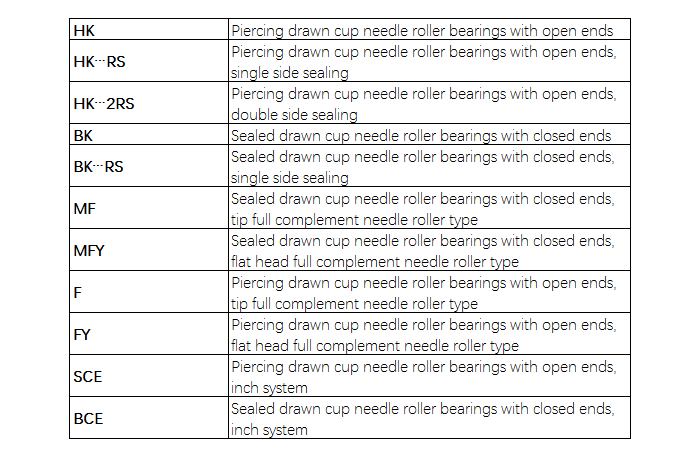

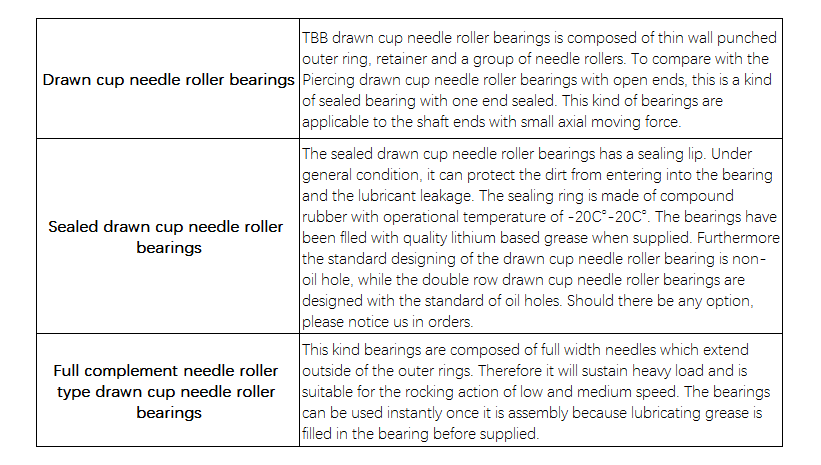

Structure

Types

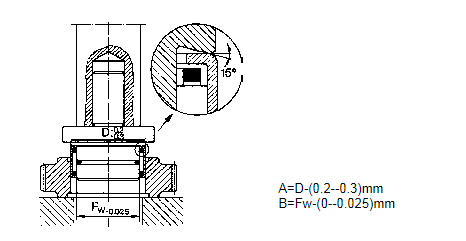

Mounting

The outer ring of the drawn cup needle roller bearings made of thin steel plate through punching will reach the correct shape and dimension precision when it is pressed into the bearing cage. Therefore, the dimensional precision and the shaped of bearing cage will directly effect the inscribed circle of the bearing. Thus enough attention must be attached to the size and shape of the bearing cage.

In mounting this kind of bearings, it will be easier to use the pressing core shaft as illustrated in the figure. Special tool must be used to press on the side with printed code mark to compress get the bearings fitted when assemblying. Direct hammer tapping is strictly forbidden. The core shaft must be made as per the requirements shown below.

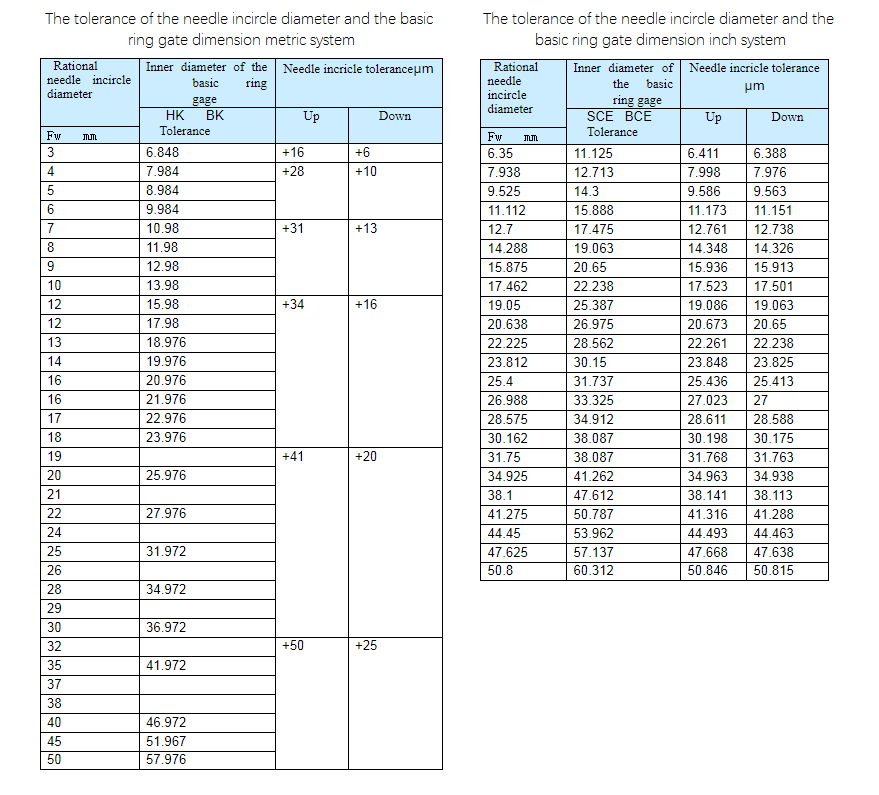

Inspection

In regard to the dimension inspection of this kind of needle bearings, it is meaningless to measure the single bearing because the bearing will deforemed after quenching due to its thin outer ring wall. That is: this kind of needle bearings must be fitted into the bearing cage according to the recommended permissible tolerances before it can reach the vital functional inscribed circle and circularity. So, the following inspection methods are recommended:

1. Press the bearing into basic gauge with rigidity shown in the list(the wall thickness is no less than 20mm)

2. Check with a feeler gage or taper gage the inscribed circle to see if it falls in the required range

Catalogue? Contact Us please~

No Comments