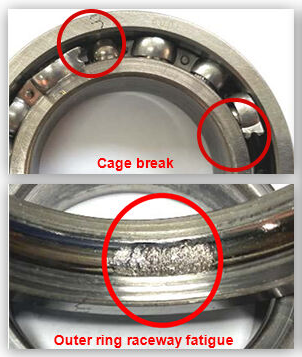

With the wide application of PWM and IGBT in motor, the problems caused by electromagnetic damage such as electric corrosion of bearing are more and more prominent. What causes electromagnetic damage …

A casual visitor was called Nove壯陽藥 l Coronavirus when we were preparing to celebrate the Spring Festival in January 2020. Because of it, billions of people in our country could not go out, the malls…

The performance of ball bearings can be critically affected by minute particles. Particles as small as 0.005mm can cause problems. To prevent such problems, we use a class 1,000 clean room throughout …

Although 2019 was a tough year, TBB have made a lot of achievements with our efforts. We hope in 2020 TBB will win customers’ heart with TBB professionalism, and make greater achievements. In the comi…

After offering we heard many times voice of “Your price is too high” or “Our current price is 50% lower than yours ” …You have explained to customer that how good quality your product is, showed…

5 Reasons to Choose TBB Needle Roller Bearing 1. Years of focusing on bearing, quality guaranteed Estabilished for many years since 1998 and is a p壯陽藥 rofessional supplier of bearings With an a…

Gearboxes are used in a very wide range of industrial fields. Thanks to the use of gearboxes, a small rotation force (torque) can be used to produce a much greater rotation force, and a slow rate of r…

The manufacturing of metal parts and components is so significant to any economic marketplace, typically, the machine tool industry is utilizing the latest technological advances in manufacturing proc…

Needle bearings are roller bearings with rollers that have high length-to diameter ratios. They are used in farm and construction equipment, automotive transmissions, small gasoline engines, gear pump…