Most rolling-element bearings are either ball or roller bearings. The roller bearing family consists basically of cylindrical, tapered, spherical, and needle bearings. Needle roller bearings are the s…

When bearing steels are in their soft (unhardened) state, metallurgists refer to their structure as being in the pearlite state. In order to harden the steel it must be heated to a very high temperatu…

In our previous blog entry, we examined static and dynamic load ratings for spherical plain bearings. This week, we continue our look into this bearing segment with some further information on the ope…

We have assembled a wide variety of frequently asked questions (FAQs) about bearings (e.g. ball bearings, roller bearings, plain bearings, linear bearings) and bearing related products (and bearing se…

1) High carbon chromium bearing steel High carbon chromium bearing steel specified in JIS is used as a general material in bearing rings (inner rings, outer rings) and rolling elements (balls, rollers…

Since the characteristics of materials used for cages greatly influence the performance and reliability of rolling bearings, the choice of materials is of great importance. It is necessary to select c…

In shipping bearings, since they are covered with proper anti-corrosion oil and are wrapped in antitarnish paper, the quality of the bearings is guaranteed as long as the wrapping paper is not damaged…

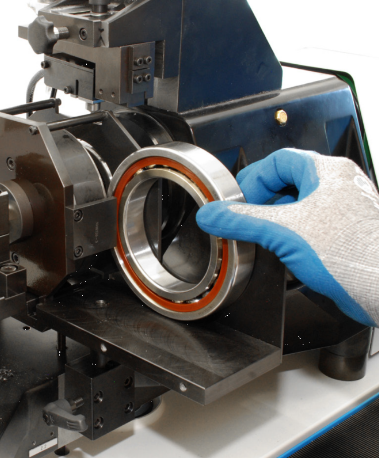

Periodic and thorough maintenance and inspection are indispensable to drawing full performance from bearings and lengthening their useful life. Besides, prevention of accidents and down time by early …

In selecting bearings, the most important thing is to fully understand the operating conditions of the bearings. The main factors to be considered are listed below: 1.Installation space Bearing can be…

Bearings with diameters between 36 and 169 in. typically cost a lot and have long lead times, forcing end users to keep spare bearings on hand or face extensive downtime should a bearing fail. Therefo…