Since bearings are metallic products they rust easily. So their treatment requires certain precautions. 1. When handling bearings, use finger caps, pincers or gloves that do not generate cotton fibers. 2. When you must use naked fingers, first make sure they are clean and free from perspiration and dust. Then apply a quality mineral oil to the fingertips before touching the bearings. Do not use hand cream, as it may induce rust. 3. If a shaft is dirty on the surface, rust may gather between the shaft and the bearing after they are fitted. So it is important to make certain the shaft is free from finger prints and perspiration. 4. When handling bearings choose a place that is dry. Always place the bearing boxes on a shelf or pallet. Avoid placing the boxes directly on the floor or other locations where moisture and dirt may be present. 5. Avoid storing bearings near air conditioners and direct sunlight. Bearings may rust when placed near an air conditioner outlet or any place where wind or sunlight can enter directly. 6. A great temperature variance may cause condensation to form on bearings. In colder climates allow the bearings to reach room temperature…

The performance of ball bearings can be critically affected by minute particles. Particles as small as 0.005mm can cause problems. To prevent such problems, we use a class 1,000 clean room throughout our bearing assembly operation. “Keeping bearings clean” is the most important rule of bearing use. Avoid exposing bearings to any environment where particles may be present. Once inside a bearing, such particles can cause raceway scratches, abrasion and shortened life. They can also generate acoustic noise and vibration. We use shields or seals to keep particles out. But there is still a gap between the shield and inner ring of shields and non-contact seals. This gap may permit particle entry. So it is important to observe the following procedures carefully. 1. Keep your bearing handling area as clean as possible. 2. Do not remove the bearings from their packaging until just before use. If you move the bearings to a container, be sure the container is clean. Its lid should be kept closed and it should be cleaned every day to prevent particle accumulation. 3. Never use a bearing that has been dropped. It may be brinelled (race track dented). In use, a brinelled bearing will generate a…

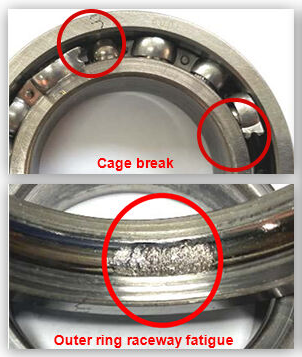

After offering we heard many times voice of “Your price is too high” or “Our current price is 50% lower than yours ” …You have explained to customer that how good quality your product is, showed your testing reports with thousands times, because you know clearly the difference between products of different price level. How do you prove it? Yes, taken inspection for these different products is a good method . TBB did so.However, the testing of basic data such as size, clearance, precision, vibrate. Sometimes there have very big different on measurement, but sometimes there do not have very obvious different on data. What is the deep reason for big price gap? To end the confusion, TBB did further testing- Life Reliability Comparison Test at National Bearing Testing & Inspection Institute.A group of 4 piece of deep groove ball bearings, after rigorous and reasonable experimental process: Firstly, can you guess how the bearings performed ? Here comes some pictures to show how it performance. Secondly, can you guess how many hours the bearings lasting? Here comes the testing results. #1 bearing from TBB OEM product, it lasting for 121.5 hours till the testing ended with good condition.#2 bearing from world well-known second-class…

Gearboxes are used in a very wide range of industrial fields. Thanks to the use of gearboxes, a small rotation force (torque) can be used to produce a much greater rotation force, and a slow rate of revolution can be speeded up. In many industries, the gearbox, which is the equipment that transmits mechanical power, is an essential piece of equipment. This step-up unit is the: heart of a wind turbine transmission in an automobile the reduction gears in a Ferris wheel By supplying bearings for gearboxes such as these in support of their most important function: “revolving,” we believe that it can even be said to be supporting the world. However, because there are many instances where the breakdown of a gearbox would have serious implications, extremely high reliability is demanded. Naturally, we seek to ensure that its designs closely match customer needs, and the company is always aiming to enhance product quality. We supply bearings that offer long life to reduce equipment maintenance costs, can handle high load capacities, and are extremely reliable. We will continue to pool our comprehensive strengths. With environmental issues firmly in its sights, our company will continue product development efforts so that it…

At this year’s Hannover Messe in Germany, bearing manufacturer NKE Austria GmbH presents bearings with black oxide finish. The protective layer improves run-in and wear characteristics and protects against environmental effects. Especially in critical applications such as wind turbine gear boxes, black oxide finish is a cost-effective and technically viable means of prolonging the service life and performance of rolling bearings. The black oxide finish forms a protective layer for steel parts. In a multistage chemical process, the surface layer of the treated parts is converted into a 1 to 2 micrometer thin mixed ferrous oxide layer that causes the characteristic black appearance. Black oxide finished bearing components feature a set of special technical characteristics, especially in the case of components that move relative to each other. Multiple protective effects can be achieved if only one functional element (typically the rolling elements) is treated. For best effect, however, all functional surfaces of a rolling element bearing, including the inner and outer ring as well as the rolling elements, should be black oxide finished. Black oxide finishing is already an established method in other industries. NKE uses this technology to further improve the technical properties of rolling bearings. The method has…

TBB drawn cup needle roller bearings is formed with thin steel plate through precision punching with very sectional height and big load capacity. This kind of bearings are especially applicable to the big quantity production with economic demands. Stable combination is used between the needle bearings and the bearing cage. No axle fixture is required. Even under high speed and heavy load condition, the bearing functions can be fully maintained. Furthermore, no lubricating for a long time is possible due to its high storage volume of grease. Structure Types Mounting The outer ring of the drawn cup needle roller bearings made of thin steel plate through punching will reach the correct shape and dimension precision when it is pressed into the bearing cage. Therefore, the dimensional precision and the shaped of bearing cage will directly effect the inscribed circle of the bearing. Thus enough attention must be attached to the size and shape of the bearing cage. In mounting this kind of bearings, it will be easier to use the pressing core shaft as illustrated in the figure. Special tool must be used to press on the side with printed code mark to compress get the bearings fitted when assemblying….

Material Cronidur30ISO Standard: DIN 1.4108Chemical formula: X30CrMoN15-1Advantages: Finer structure, less heat generated, higher permissible contact pressure, much higher fatigue life reliability (10x compared with GCr15 in best case), better corrosion resistance and high temperature resistance Material Ceramic Si3N4Advantages: Excellent tribological properties, lower density to improve the bearing kinematics, lower coefficient of thermal expansion, no magnetism, high current insulation

A GROWING NUMBER OF “BARGAIN” BEARINGS are being brought into the Heavy Duty Truck and Trailer marketplace by bearing brokers whose primary emphasis is on price. They ignore the critical issues of product integrity, performance, and supplier support. Initially the price has some attraction, but testing performed by Hyatt and other major suppliers has proven that a much superior performance is achieved from a quality product provided by a reputable manufacturer. For tapered roller bearings to achieve their Maximum Life in application (L10 Life), the load must be evenly distributed over the length of the rollers. To ensure proper distribution of bearing loads, Hyatt Tapered Roller Bearings are manufactured with a crown on the raceways and rollers. In our experience, the “bargain” products rarely have raceways and rollers that are crowned. Frequently the components have concave contact areas, generating even higher stresses within the bearing and promoting early catastrophic failure. Bearing brokers will state that their products conform to American Bearing Manufacturers Association (ABMA) specifications. These standards, however, only relate to the external dimensions of the bearing and its compatibility with the wheel hub and spindle. If you want a quality product which is going to provide years of uninterrupted service, then…

Wheel hub problems are often discovered while ruling out other sources for the squealing and grinding sounds coming from that area of the vehicle or the gradually increasing vibration noticed by the driver. Because such symptoms – odd noises, vibration, deterioration in handling, etc. – The common to a variety of suspension and steering system parts, it is often through the process of elimination that the need to replace this part is apparent. the it is determined for sure that this is the source of the vehicle’s problems, however, the repair Should be made as soon as possible in order to avoid causing damage to other parts or a dangerous road situation. Those that are fairly skilled at performing automotive repair projects at home are likely to find the replacement of the hub and related parts more time consuming than Challenge. Any repair is more likely to last longer when made with quality parts,Timken, Pronto, Quality-Built, WJB, Replacement, Centric, Moog, Dorman, Genuine, Beck Arnley, First Equipment Quality, DuraGo, API, NSK and Febi. (MAPC Bearings OEM for most of these brands) Wheel Hub Assembly – Time for replacement? Wheel Hub AssemblyA hub assembly, also known as a wheel hub assembly or…

Stainless steel and chrome steel are normally corrosion-resistant, not easy to rust. However, improper storage or handling at high humidity, condensation environment will reduce bearing life. How does the corrosion of bearings happen? If the bearing is prolonged exposure to water can cause rust. With the passage of time can cause peeling and crack formation, which are premature bearing failures. In addition, if the bearing is too loose or improper installated, contact corrosion will occur.. Bearing corrosion will reduce the machine performance and productivity, increasing the cost of operation. Common raceway corrosions include, bearing contact corrosion, corrosion of the outer surface and the inner ring of holes. How to prevent bearing corrosion? Prevention is the main thing. Here are some methods which can prevent bearing corrosion Use waterproof grease, it can form a protective barrier in the wet environment Add some protective coatings, such as chrome, nickel, zinc Adjust bearing, if it is suspected of contact corrosion Try to use a different material, in extremely corrosive environment, you can use ceramic bearings for example.